Method for setting temperature of electric soldering iron

A technology of setting temperature and electric soldering iron, applied in soldering iron, welding equipment, metal processing equipment and other directions, can solve the problem that the temperature cannot be set accurately, cannot reflect the influence of the temperature of the soldering iron on the pad, and cannot fully reflect the temperature performance of the electric soldering iron, etc. problem, to achieve accurate and scientific effect of temperature determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for determining the temperature of the electric soldering iron of the present invention will be further described below in conjunction with the implementation examples.

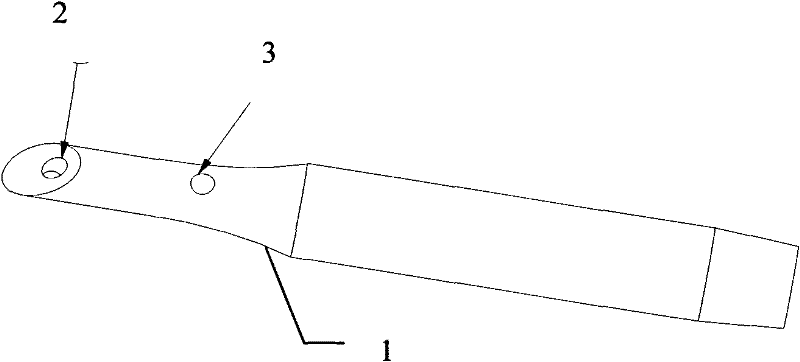

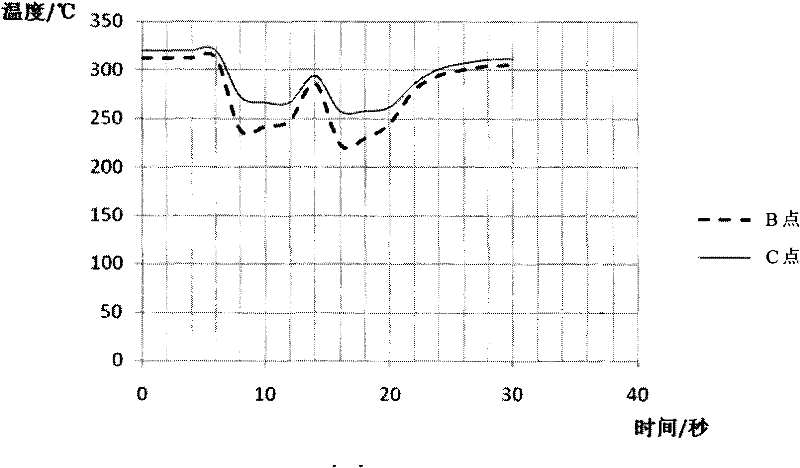

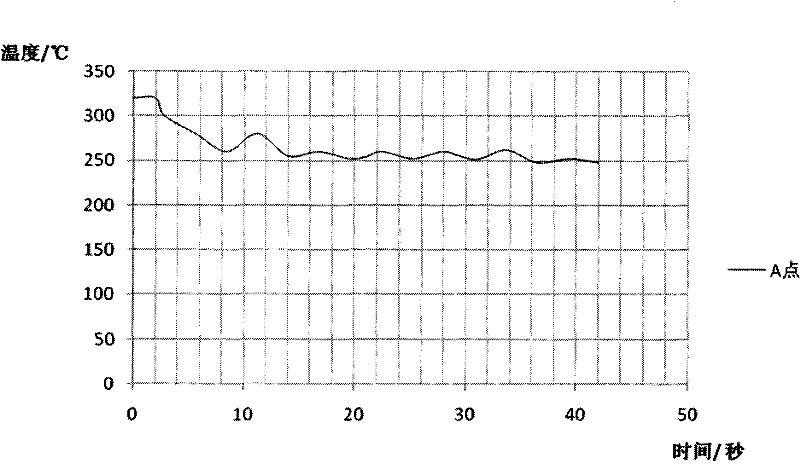

[0024] (1) Select the electric soldering iron and soldering iron tip: the optional electric soldering iron must have a temperature adjustment function; drill through holes at the tip position 2 of the soldering iron tip 1 and the rear position 3 of the front end of the soldering iron tip, and the positions of the through holes are respectively called For points B and C, install the thermocouple of the temperature tester at the through hole ( figure 1 ); Then turn on the temperature tester and weld a solder joint, the temperature tester will collect continuous temperature data, after the welding is completed, derive the temperature-time graph of point B and point C of the soldering iron tip from the temperature tester ( figure 2 ). The closer the temperature curves of point B and point C ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com