Parallel bar type anchor device for flexible flaky material and method thereof

A sheet material and anchoring device technology, which is applied in the processing of building materials, erecting/assembling bridges, structural elements, etc., can solve the problems of the size of the body, the difficulty of operation and the anchoring effect is not ideal, so as to improve the utilization efficiency and Scope of application, saving high-priced materials, reducing the effect of overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

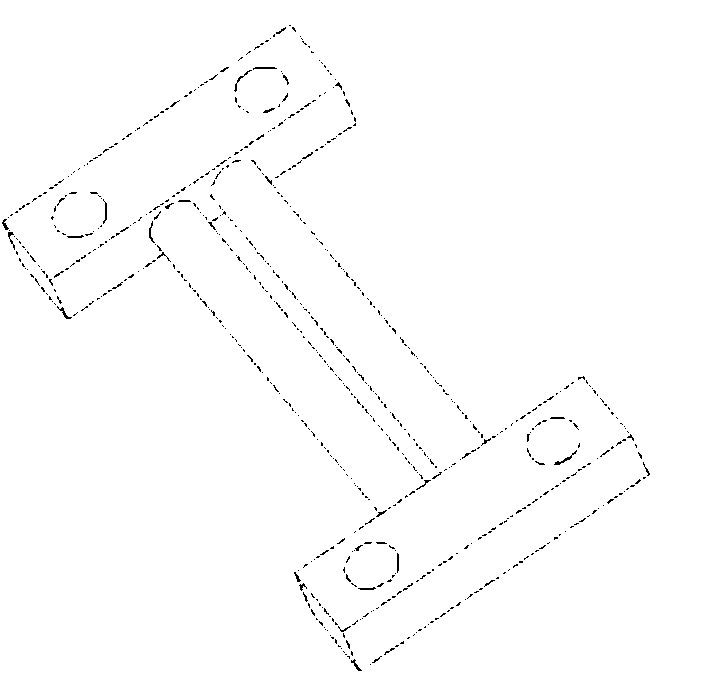

[0036] Embodiment 1: as figure 1 , 2 parallel rods are integrally combined with strip-shaped parallel pieces (can be completed by casting), and each parallel piece is provided with 2 anchor holes for the anchoring rods to pass through.

Embodiment 2

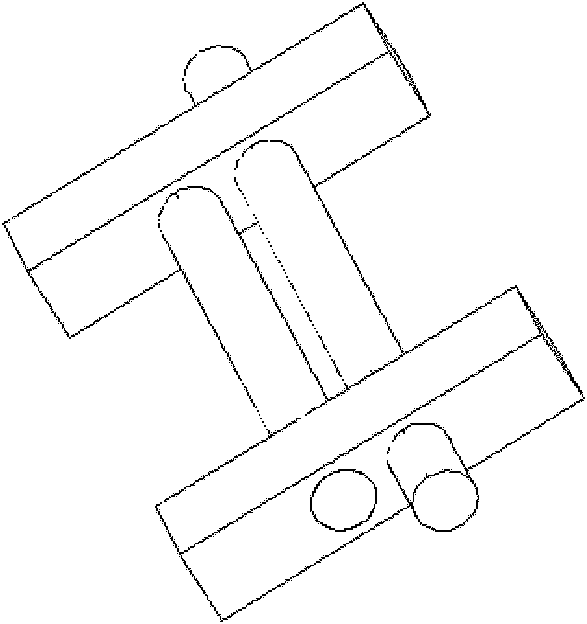

[0037] Embodiment 2: as figure 2 , 2 parallel rods penetrate into the strip-shaped parallel piece with a rod hole (assembled combination), and one of the rods passes through the protruding part of the parallel piece for insertion of auxiliary anchors with holes such as joints.

Embodiment 3

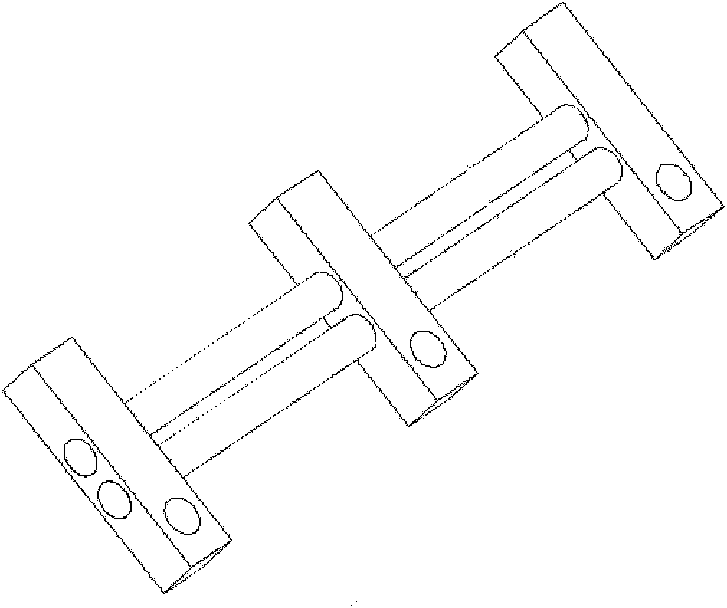

[0038] Embodiment 3: as image 3 , 2 parallel rods penetrate into the strip-shaped parallel piece with rod holes (assembled combination), 3 parallel pieces divide each rod into 2 sections, and each parallel piece is provided with 1 anchor hole for anchoring Pass through with a rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com