Method for self-lock of flexible flaky material by turnstile

A technology of flexible sheets and sheet materials, which is applied in the processing of building materials, building maintenance, fixing devices, etc., can solve the problems of anchor failure, volume size, and operation difficulty, and the anchoring effect is not ideal, so as to reduce the overall The effect of cost, improvement of utilization efficiency and scope of application, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

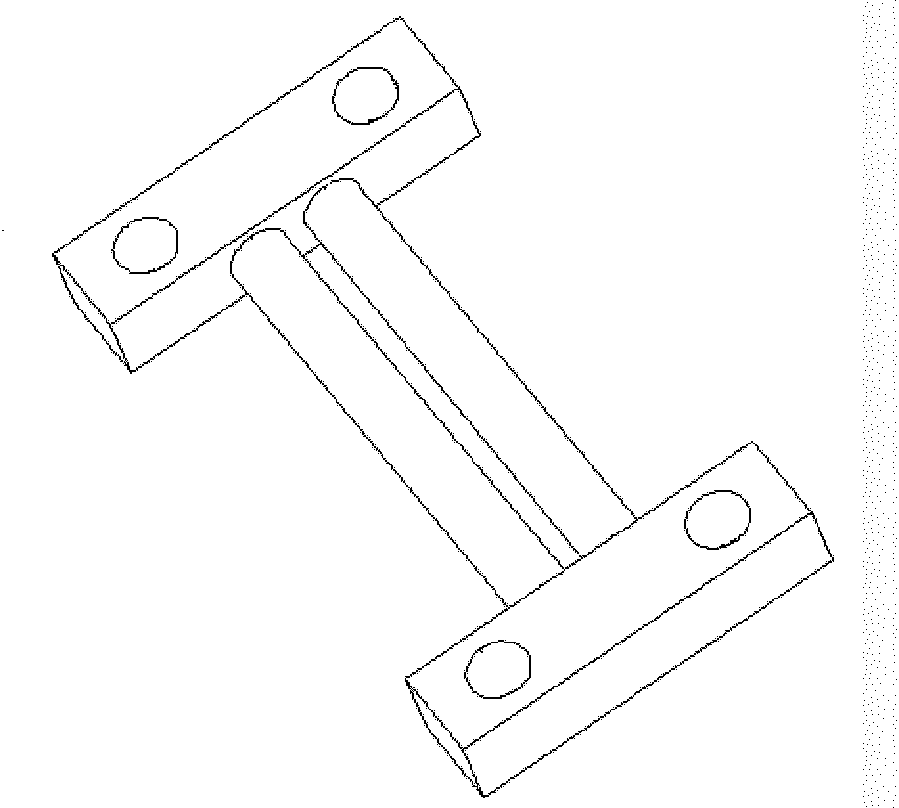

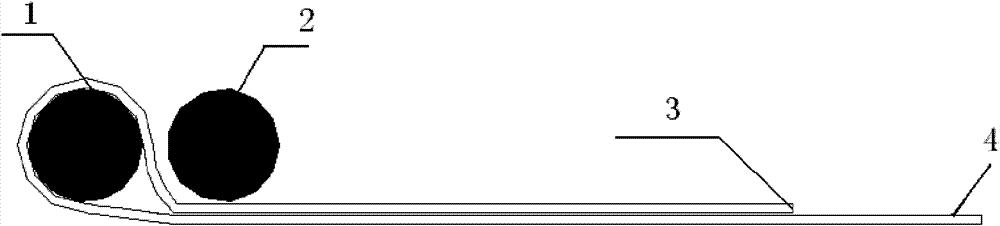

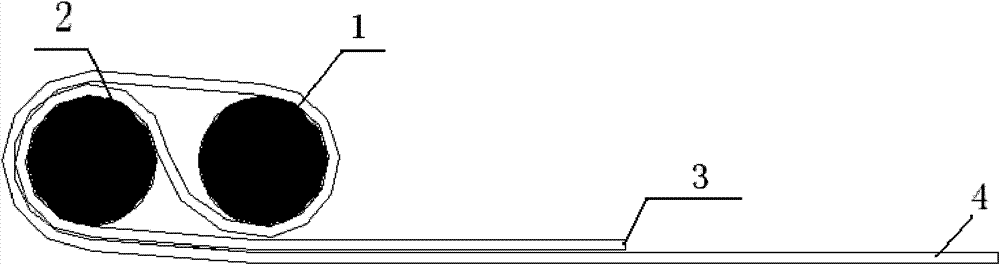

[0033] Such as Figure 1-3 , figure 1 It is a schematic diagram of an embodiment of a flexible sheet material parallel rod anchoring device. Because there are only two rods and they are shaped like parallel bars, they may be called parallel bar anchors or II-shaped anchors. The following takes the application of the double bar anchor as an example, combined with the attached figure 2 , 3 The method of using the device to self-lock around the rod on flexible sheet materials is described.

[0034] And the one-layer flexible sheet-like material or the multi-layer flexible sheet-like material stacked together in the initial state are collectively referred to as one-layer flexible sheet-like material. Lay one sheath of flexible sheet material around one rod to form a knot ( figure 2 , this rod is called the main rod), one hand pinches the laminated flexible sheet material near the end of the sheet and does not move, and then uses the other hand to wrap the double bar anchor a...

Embodiment 2

[0038] In Example 1, the flexible sheet material is wound only once on the rod, in fact, the flexible sheet material can also be wound multiple times on the rod, Figure 4 In the case of two turns, the self-locking effect can also be obtained.

Embodiment 3

[0039] Embodiment 3: Using 4 parallel rods, the winding mode of the flexible sheet material on the rods is as follows Figure 5 As shown, the self-locking effect can also be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com