Commutating structure for disc type permanent magnet motor

A permanent magnet motor, disc technology, applied in electrical components, electromechanical devices, etc., can solve the problems of increasing the weight, size and cost of the motor, and complicating the overall structure and shape of the motor, achieving compact structure, reducing external dimensions and weight. , the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the teachings of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms also fall within the scope defined by the appended claims of the present application.

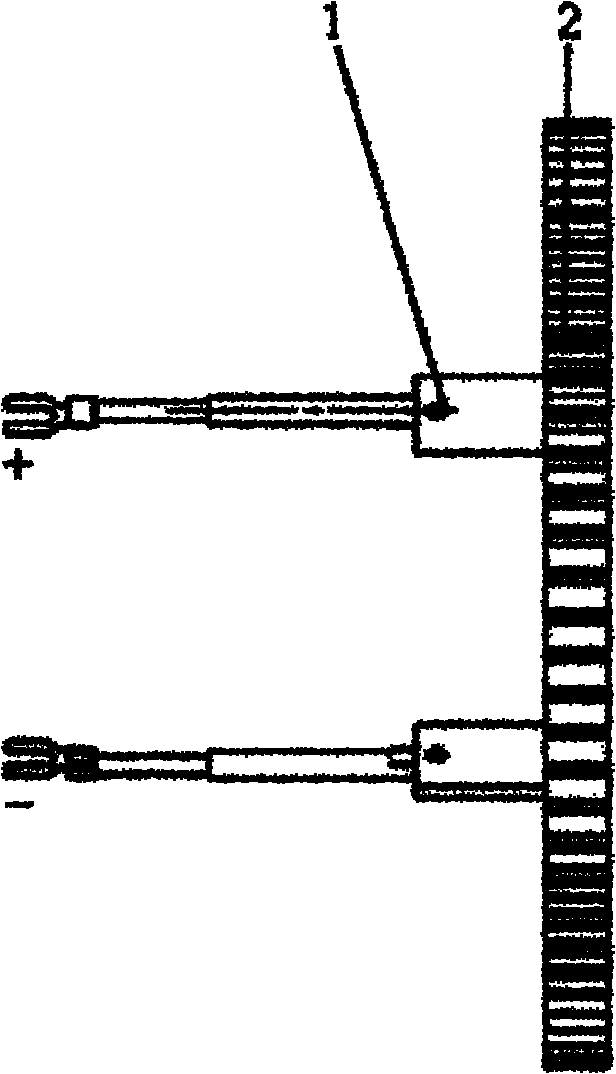

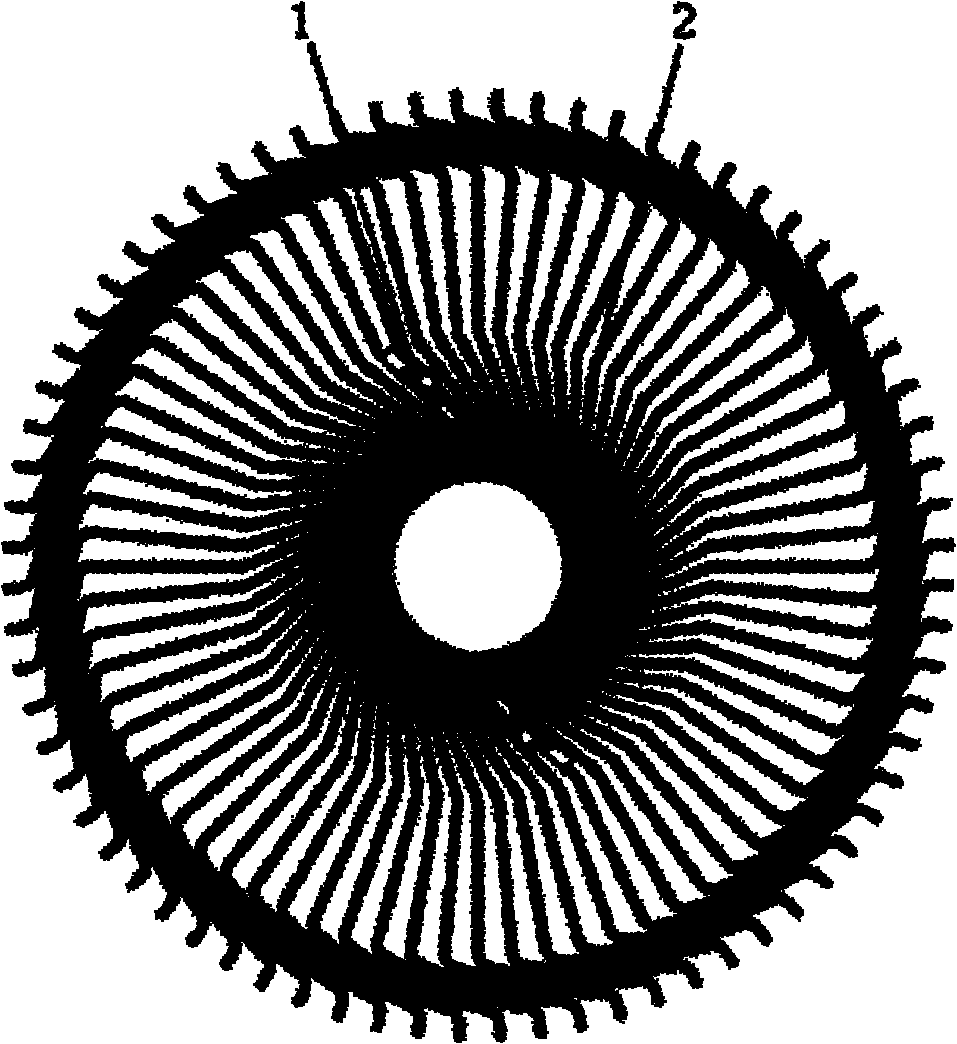

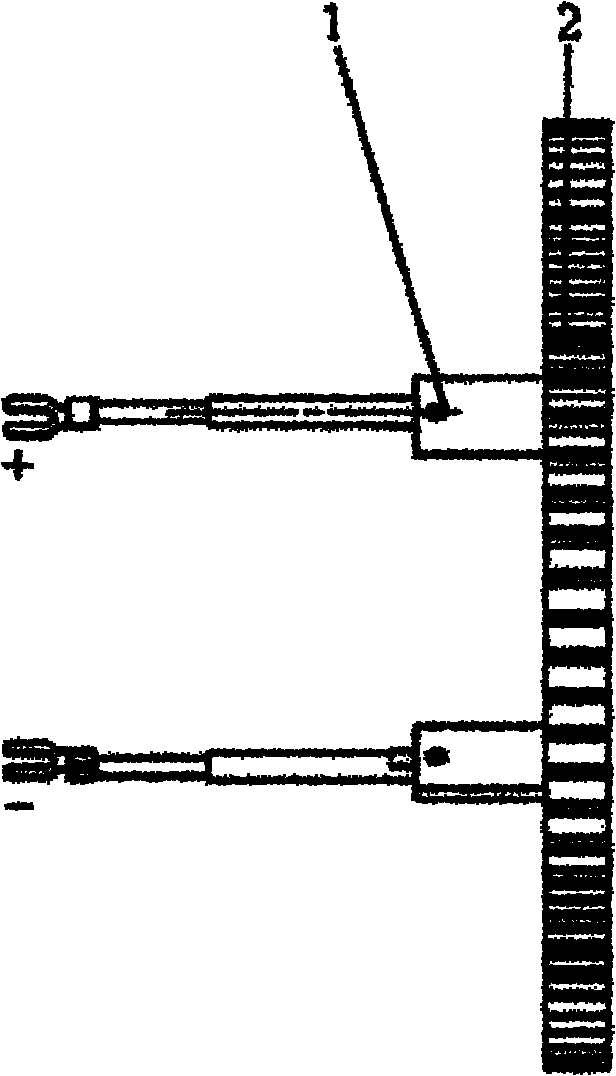

[0011] Embodiments of the present invention relate to a commutation structure of a disc permanent magnet motor, such as figure 1 and figure 2 As shown, it includes brushes and armature windings. The conductor part of the armature windings is formed by laminating and connecting formed coils in series; the brushes are divided into positive and negative poles, which are arranged in the center of the armature winding , and in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com