Filling machine packaging bag follow-up sealing device

A sealing device and packaging bag technology, applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of low working efficiency of equipment, consumption of effective time, frequent start of the turntable, etc., and achieve good sealing effect, reliable performance, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with embodiment and accompanying drawing.

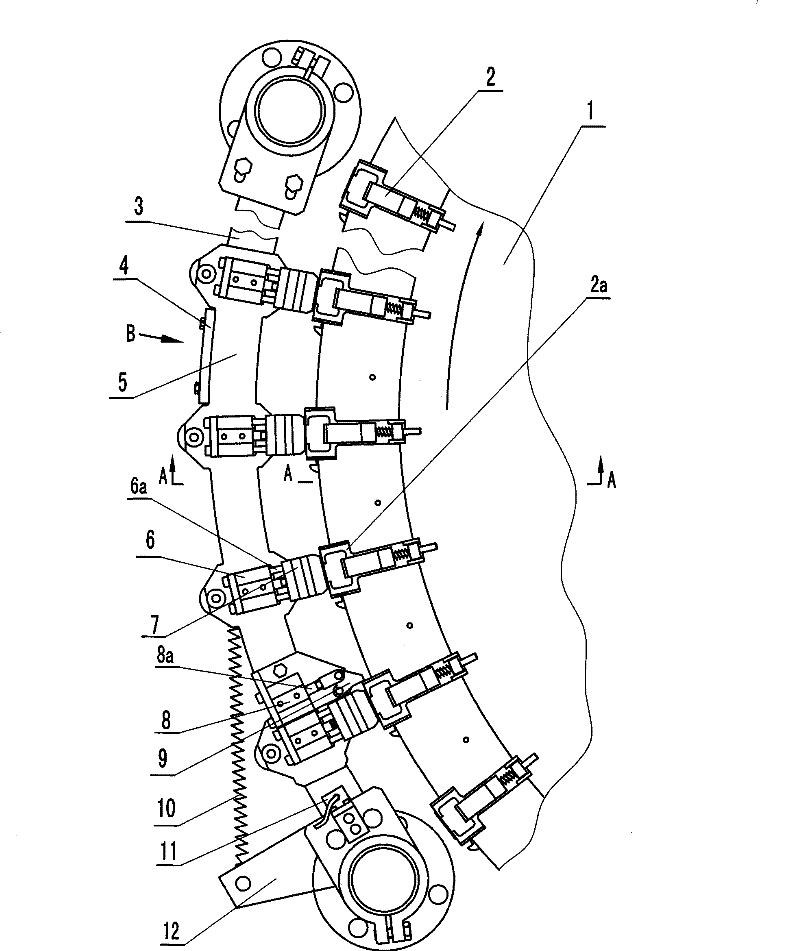

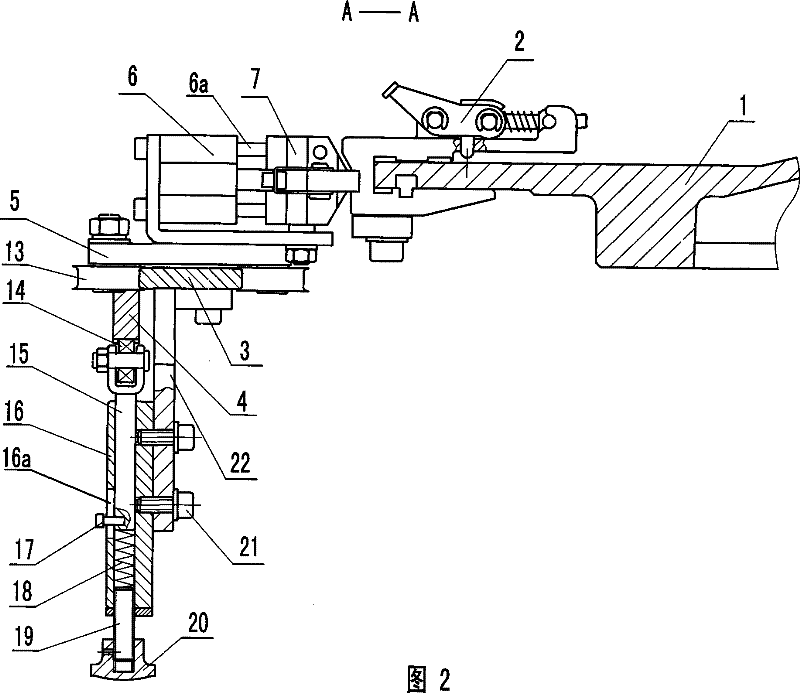

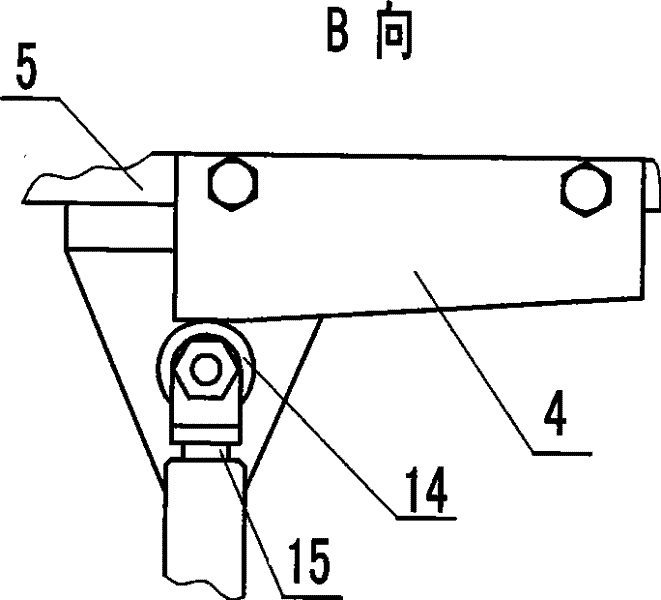

[0011] see figure 1 , figure 2 , The packaging bag follow-up sealing device of the filling machine has a turntable 1 and several clamping components 2, and the clamping components 2 are evenly distributed on the edge of the turntable 1. There is a track 3 on the outer side of the turntable 1, and the track 3 is equipped with a sliding seat 5 slidingly matched with it. On the sliding seat 5, several sealing assemblies corresponding to the clamping assembly 2 on the turntable 1 are installed. The sealing assembly includes a cylinder 6 and a sealing head. 7. The cylinder 6 is fixed on the sliding seat 5, and the head 7 is connected with the front end of the piston rod 6a of the cylinder 6. A damping projection 4 is fixed on the edge of the sliding seat 5 .

[0012] see figure 1 , the blocking member on the turntable 1 is the base 2a of the clamping assembly 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com