A kind of electronic throttle control method

A control method and electronic throttle technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of short service life, affecting the reliability and safety of the electronic throttle control system, and easy damage, and improve safety. and comfort effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

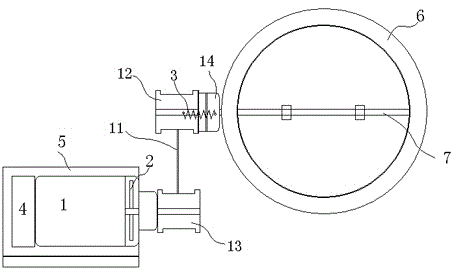

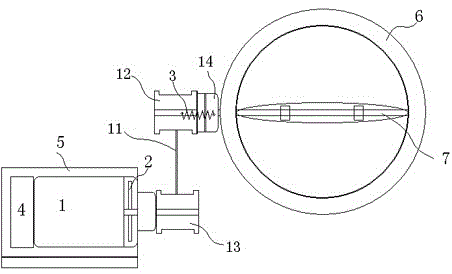

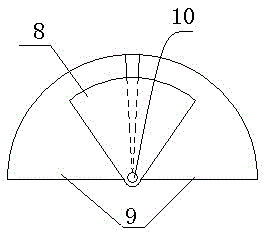

[0020] Such as figure 1 with figure 2 Shown, a kind of electronic throttle control method, it comprises at least: motor 1, angle sensor, return spring 3, controller 4, throttle valve 6 and the throttle control shaft 7 of throttle valve 6, it is characterized in that: throttle valve 6 The throttle control shaft 7 is connected to the shaft sleeve 12, and the shaft sleeve 12 is connected to the motor shaft sleeve 13 through the pull wire 11. The motor 1 and the controller 4 are fixed in the housing 5, and the output shaft between the motor shaft sleeve 13 and the motor 1 There is a differential capacitive angle sensor 2 between 10, two fixed electrode pieces 9 of the differential capacitive angle sensor 2 are fixed to the housing 5, and a moving electrode piece 8 of the differential capacitive angle sensor 2 is connected to the output of the motor 1 The shaft 10 is fixed, and the controller 4 controls the rotation of the motor 1 according to the command of the controller 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com