Liquid crystal display device and driving method of the same

A liquid crystal display device and liquid crystal layer technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of increased spacer condensation, poor alignment around the spacer, poor alignment, etc.

Active Publication Date: 2011-01-26

STANLEY ELECTRIC CO LTD

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the inventors of the present application found that when the distance between the two substrates was further shortened for the purpose of improving the response speed of the vertical alignment liquid crystal display device, alignment defects around the spacers tended to occur.

In the above case, there is a tendency that the smaller the particle size of the spacer is, the more the number of particles per unit area is required to make the distance between the two substrates uniform, and this is considered to lead to an increase in the aggregation of the spacers.

Although a layer with alignment control force is mostly applied on the surface of the spacer so as not to disturb the alignment of the liquid crystal molecules, even after such treatment, when the spacers cohere with each other, it is easy to produce poor alignment around the spacer. , and the poor alignment is also easily recognized as a bad display in appearance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

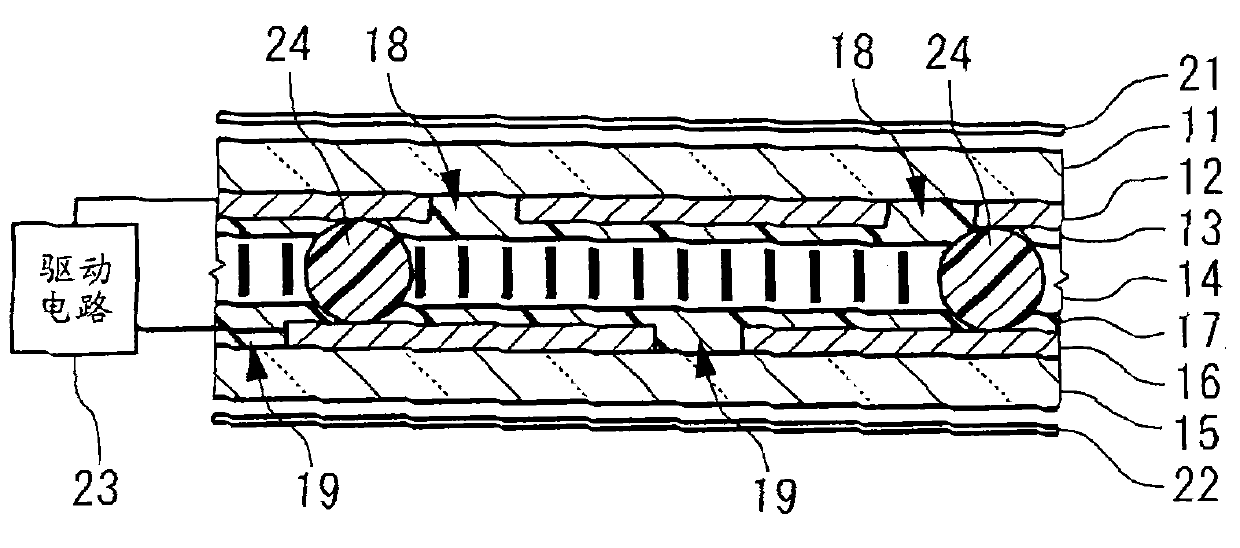

The invention relates to a liquid crystal display (LCD) and a driving method of the same. Bad display caused by mutual cohesion of spacers is reduced. The LCD device is provided with a first substrate equipped with a first electrode at one side; a second substrate equipped with a second electrode at one side, wherein the second substrate is configured corresponding to the first substrate in a manner that the second electrode thereof is corresponding to the first electrode of the first substrate; vertical alignment films arranged on the opposite surfaces of the first and the second substrates; a liquid crystal layer arranged between the first substrate and the second substrate with thickness of d and distortion spacing of p; a plurality of granular solids dispersedly arranged between the first substrate and the second substrate; and a driving circuit connected with the first electrode and the second electrode to perform multiplex drive with duty ratio of 1 / N and offset ratio of 1 / B. the driving circuit performs the multiplex drive after meeting the following conditions: d / p is not less than 0.135+0.3 / N.

Description

technical field The invention relates to a driving technology of a liquid crystal display device. Background technique Liquid crystal display devices are widely used, for example, as information display units in various consumer and vehicle-mounted electronic devices. A general liquid crystal display device has a structure in which a liquid crystal layer made of a liquid crystal material is disposed between two substrates that are disposed facing each other with a gap of about several μm. Spherical particles made of silicon dioxide, plastic, etc. are dispersed as spacers between the two substrates to maintain a uniform gap between them. For example, as shown in Japanese Patent Application Laid-Open No. 2002-148635 (Patent Document 1), as a method of spreading spacers, there are dry spreading method and wet spreading method. dry dispersion method. However, the inventors of the present application found that when the distance between the two substrates was further shortene...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02F1/1339G02F1/1333G02F1/133G02F1/1337

Inventor 岩本宜久

Owner STANLEY ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com