Preparation method of Ir and Ir-Pt/C alloy nano-catalyst with high dispersion and high load capacity

A nano-catalyst, high-dispersion technology, applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical instruments and methods, etc., can solve the technical difficulties of Ir and Ir alloy nano-catalysts, Ir and Ir Ir-based alloy nanoparticles are large in size and difficult to reduce Ir precursor compounds, etc., to achieve good industrial application prospects, increase specific surface area, and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation steps of Ir / C catalyst with Ir loading of 5wt% are as follows:

[0023] 1. Add 50ml double distilled water to 100mg carbon black carrier, ultrasonic for 20 minutes, add KBH 4 Form a solution with a concentration of 1 mol / L, stir and react for 8 hours, filter, wash with 50ml of secondary water, and dry in vacuum at 60°C for 2 hours to obtain modified carbon black;

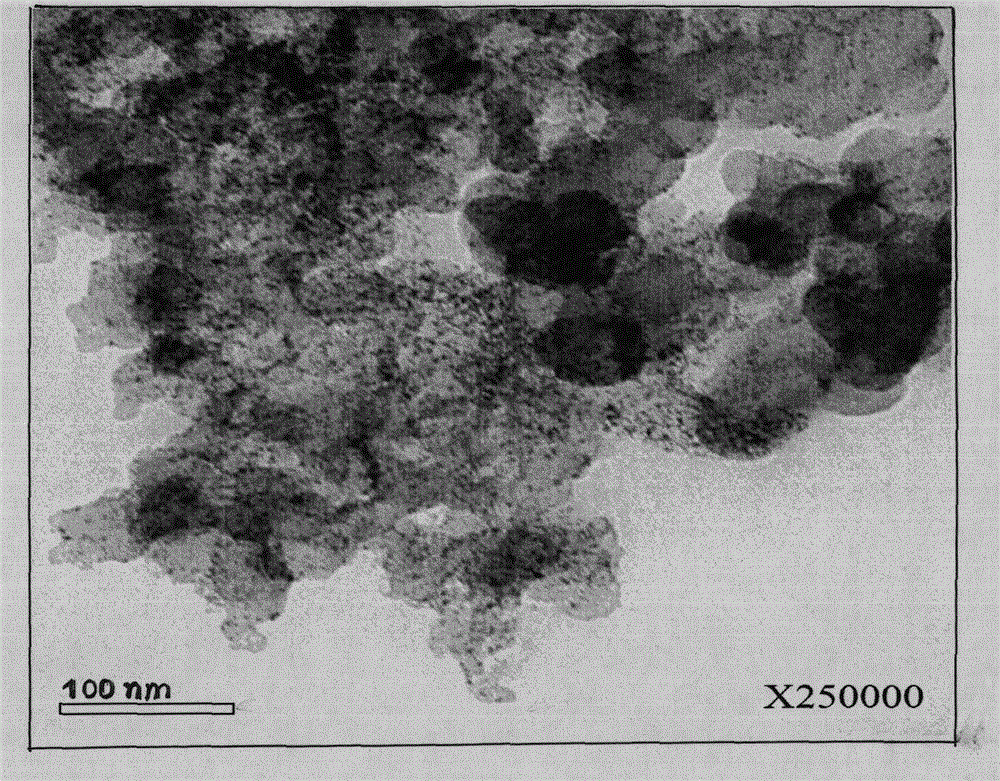

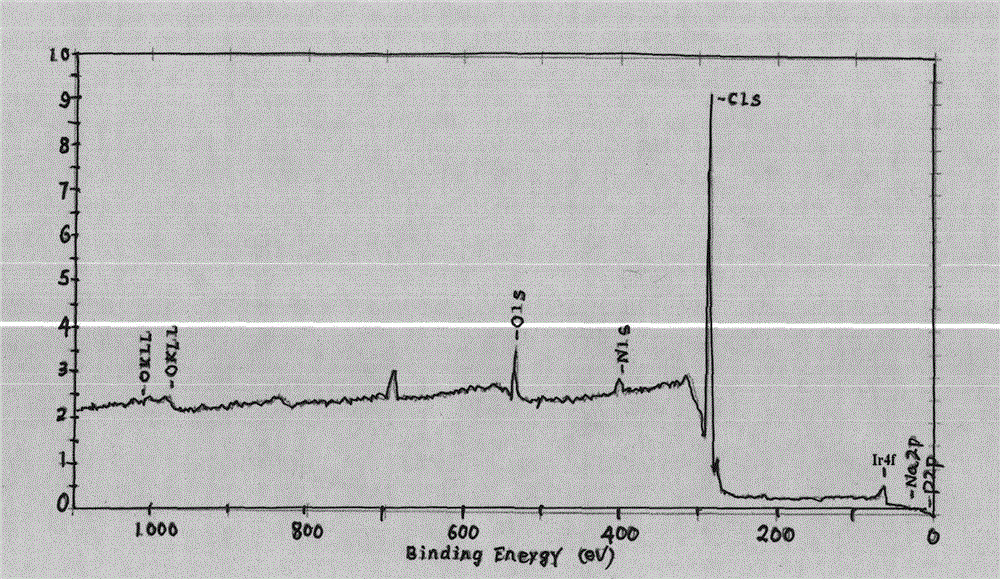

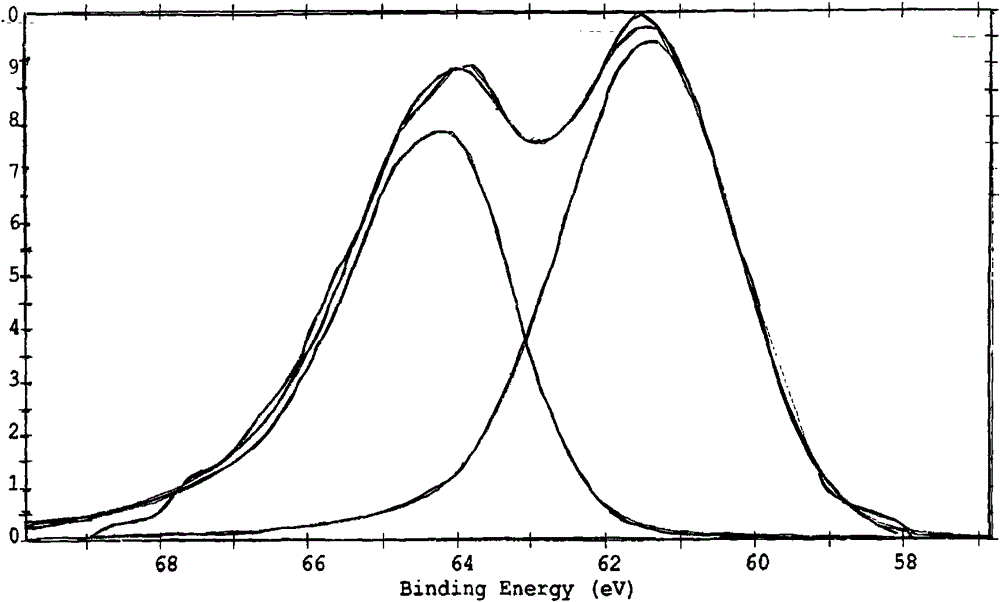

[0024] 2, in the 20ml chloroiridic acid aqueous solution that Ir content is 0.01wt%, adding 1.0ml mass fraction is 1% polyvinylpyrrolidone to do protective agent, stirs 20 minutes, adds the carbon black carrier after 38mg modified treatment, Ir: carbon Mass ratio of black = 5.26:100 Ultrasound for 30 minutes; move the dispersed reaction solution into a high-pressure reactor, pass hydrogen to 4MPa, then heat up to 150°C, react for 7 hours, after cooling to room temperature, filter and wash with double distilled water to no detectable Cl - , 60 ° C vacuum drying for 1 h to obtain a highly disp...

Embodiment 2

[0026] The preparation steps of Ir / C catalyst with Ir loading of 10wt% are as follows:

[0027] 1. Add 50ml double distilled water to 100mg carbon black carrier, ultrasonic for 20 minutes, add KBH 4 Form a solution with a concentration of 1 mol / L, stir and react for 8 hours, filter, wash with 50ml of secondary water, and dry in vacuum at 60°C for 2 hours to obtain modified carbon black;

[0028] 2, in the 20ml chloroiridic acid aqueous solution that Ir content is 0.02wt%, adding 1.0ml mass fraction is 1% polyvinylpyrrolidone to do protective agent, stirs 20 minutes, adds the carbon black carrier after 36mg modified treatment, Ir: carbon Mass ratio of black = 11.1:100 Ultrasound for 30 minutes; move the dispersed reaction solution into a high-pressure reactor, pass hydrogen to 4MPa, then heat up to 150°C, and react for 7 hours. After cooling to room temperature, filter and wash with double distilled water to no detectable Cl - , Vacuum drying at 60°C for 2h to obtain a carbon...

Embodiment 3

[0030] The preparation steps of Ir / C catalyst with Ir loading of 20wt% are as follows:

[0031] 1. Add 50ml double distilled water to 100mg carbon black carrier, ultrasonic for 20 minutes, add KBH 4 Form a solution with a concentration of 1 mol / L, stir and react for 8 hours, filter, wash with 50ml of secondary water, and dry in vacuum at 60°C for 2 hours to obtain modified carbon black;

[0032] 2, in the 20ml chloroiridic acid aqueous solution that Ir content is 0.03wt%, adding 4.0ml mass fraction is that 1% polyvinylpyrrolidone is made protecting agent, stirs 20 minutes, adds the carbon black carrier after 24mg modified treatment, Ir: carbon Mass ratio of black = 25:100 Ultrasound for 30 minutes; move the dispersed reaction solution into a high-pressure reactor, pass hydrogen to 4MPa, then heat up to 150°C, react for 7 hours, after cooling to room temperature, filter and wash with double distilled water to no detectable Cl - , Vacuum drying at 60°C for 2h to obtain a carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com