Patents

Literature

31results about How to "Load control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

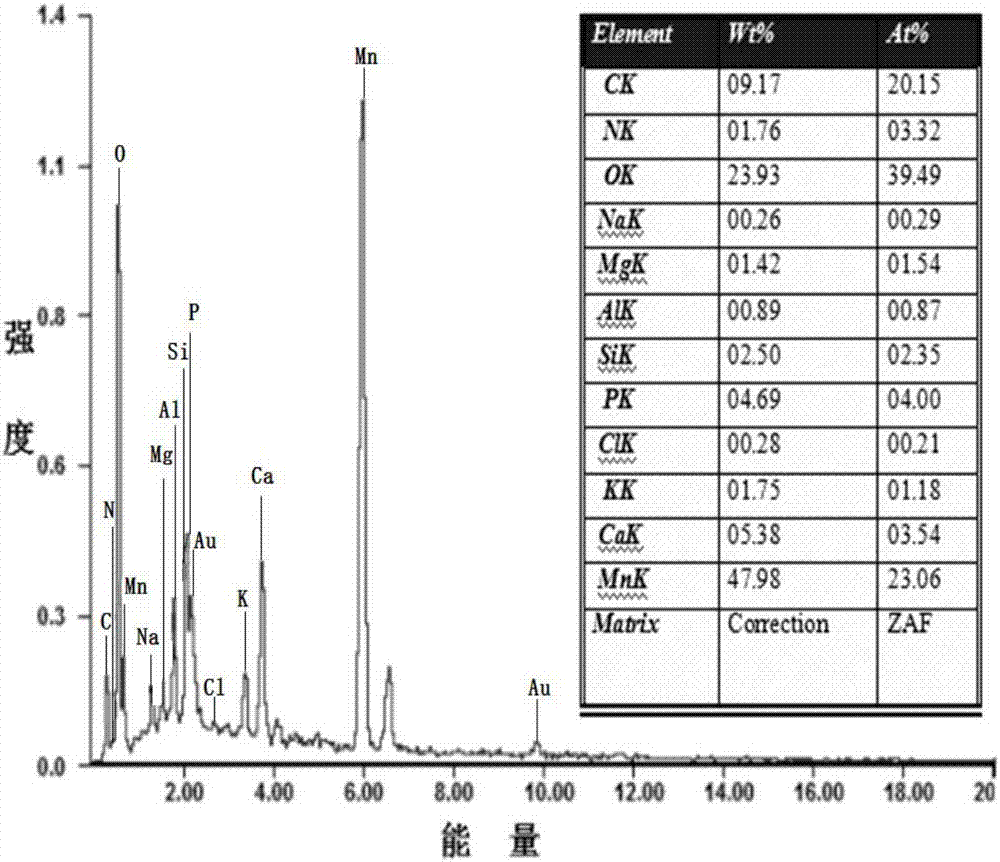

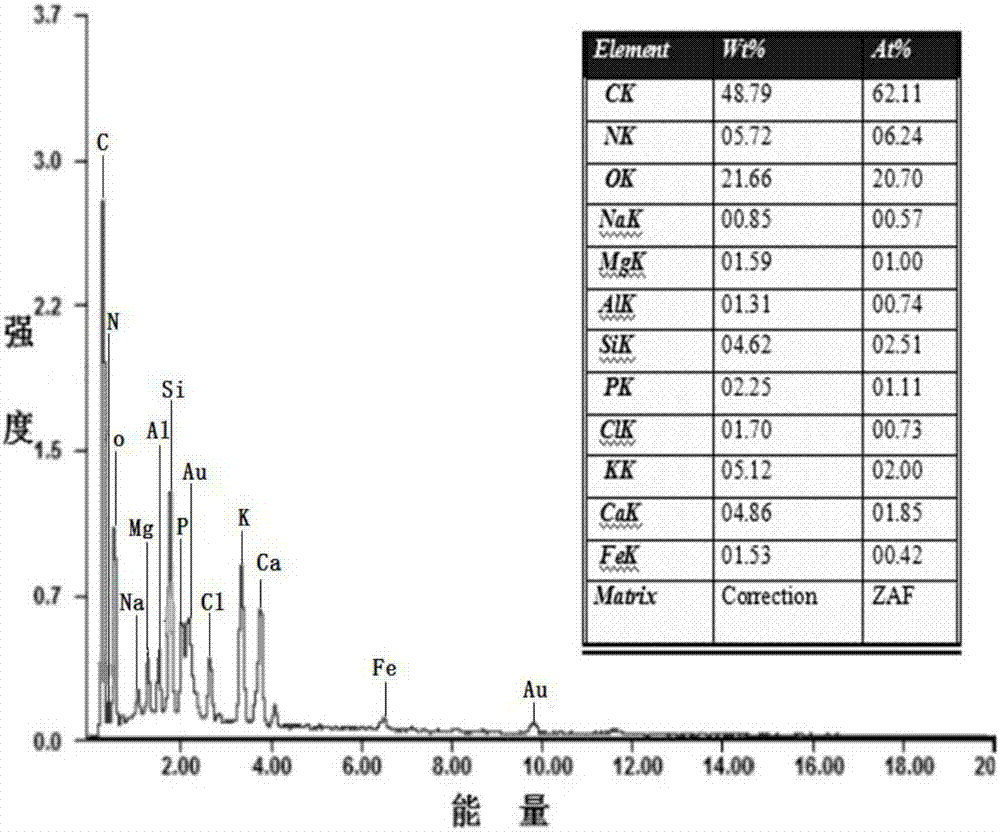

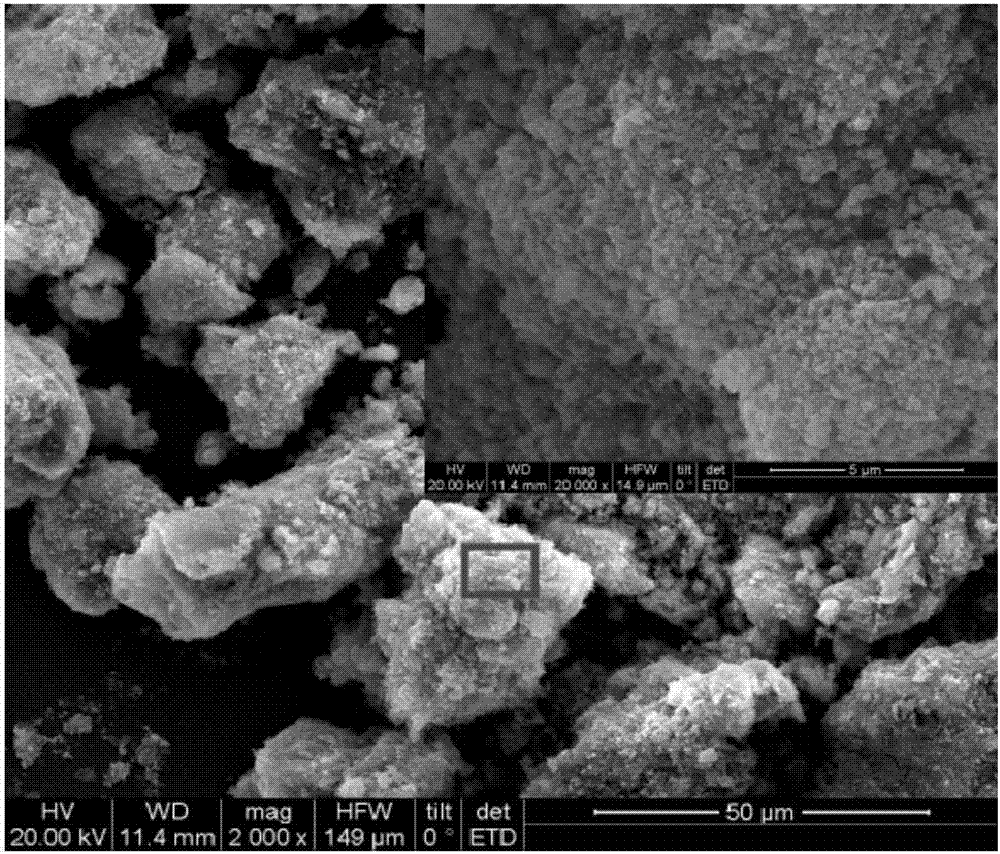

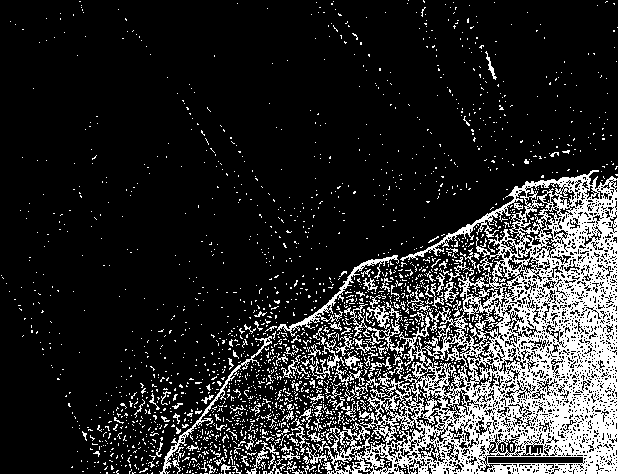

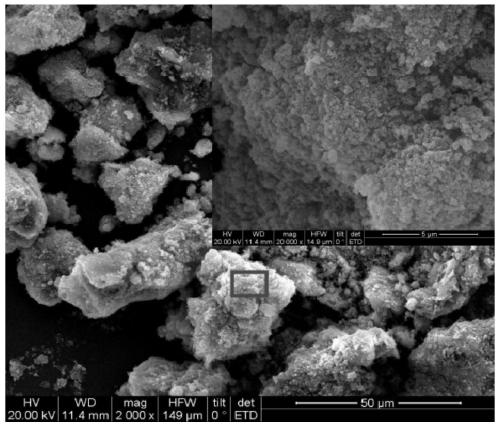

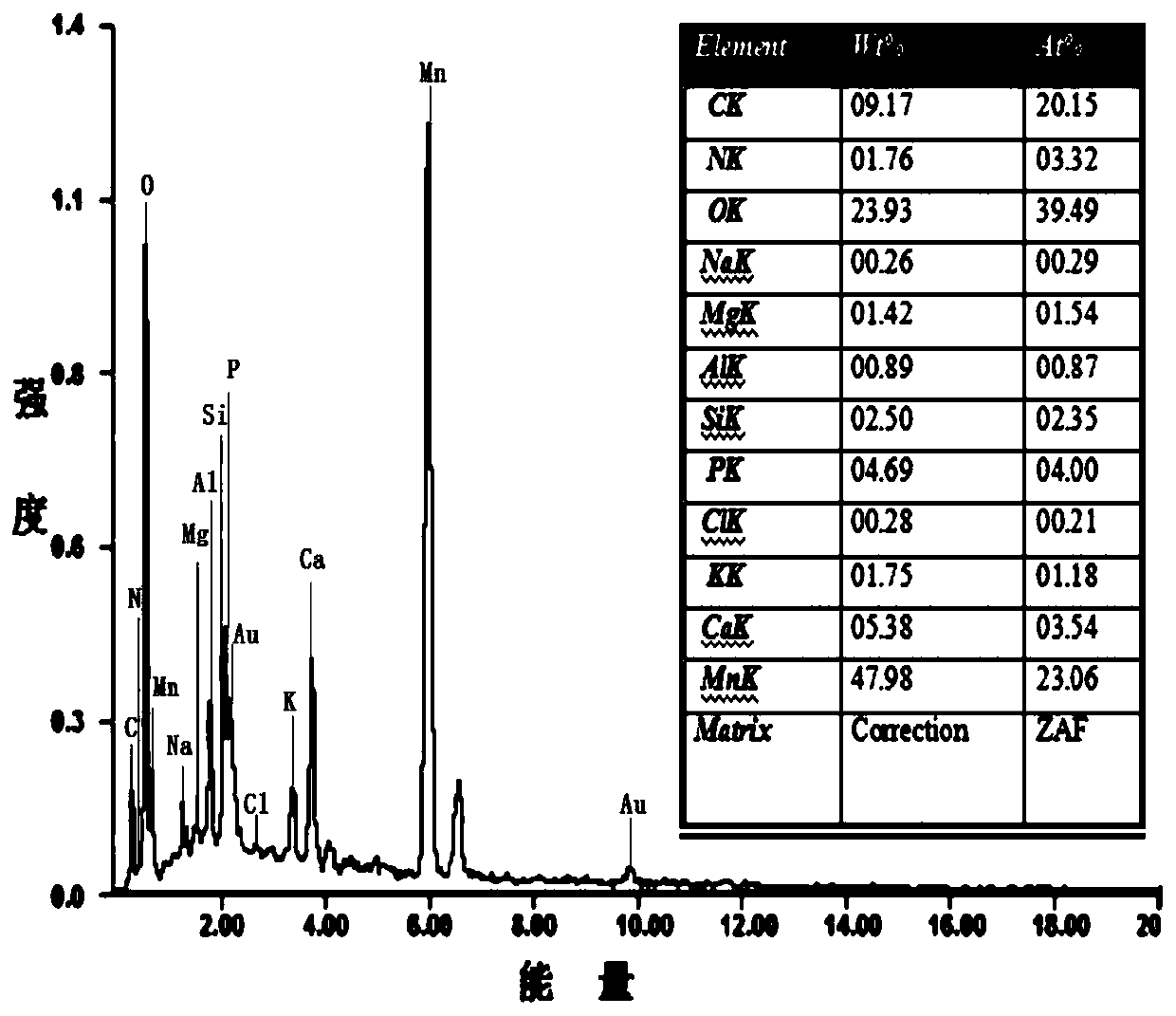

Manganese dioxide modified biochar composite material as well as a preparation method and an application thereof

ActiveCN107983300AStrong adsorption capacityGood adsorption effectOther chemical processesWater contaminantsChemistryHeavy metals

The invention discloses a manganese dioxide modified biochar composite material as well as a preparation method and an application thereof. The composite material is prepared from manganese dioxide and biochar by loading generated manganese dioxide on biochar through the neutralization reaction of permanganate and manganese in divalent manganese salt. The manganese dioxide modified composite material has the advantages of high adsorption capacity for heavy metal lead or cadmium, obvious adsorption effect, low preparation cost and the like, and is an ideal heavy metal wastewater adsorbent; thepreparation method of the composite material has the advantages of simple process, cheap raw materials, sufficiently used raw materials, low production cost and the like. The manganese dioxide modified composite material can be used for treating heavy metal wastewater, and has the advantages of high adsorption capacity for heavy metals, high adsorption efficiency, low toxicity to organisms in theenvironment and the like, and can be produced and applied on a large scale.

Owner:HUNAN UNIV

Preparation method and applications of zinc oxide-graphene oxide composite nanomaterial

InactiveCN103734188ASolve the problem that the particle size is difficult to controlHigh antibacterial activityMaterial nanotechnologyBiocideAlcoholZinc ion

The invention discloses a preparation method of a zinc oxide-graphene oxide composite nanomaterial, which is implemented through the following steps: by taking soluble divalent zinc ions as a zinc source, taking the soluble divalent zinc ions, graphene oxide and alkali liquor as reactants together, according to a situation that the mass ratio of the zinc ions to the graphene oxide is (1-3): 1, forming a solute composition; by taking alcohol as a solvent, forming a reaction solution mixed system; and after a reaction is performed for 30 min-5 h, purifying a substrate by using centrifugation and washing methods, so that the zinc oxide-graphene oxide composite nanomaterial is obtained. The zinc oxide-graphene oxide composite nanomaterial prepared according to the invention has an effective antibacterial ability at low concentration, and has no obvious toxic action on cells. According to the invention, the operation process is simple, the reaction process has no obvious pollution to the environment, the production cost is low, and the prepared nanomaterial can be applied to the antisepsis of medical apparatuses and instruments, and has a potential in commercial large-scale production.

Owner:SHANGHAI UNIV

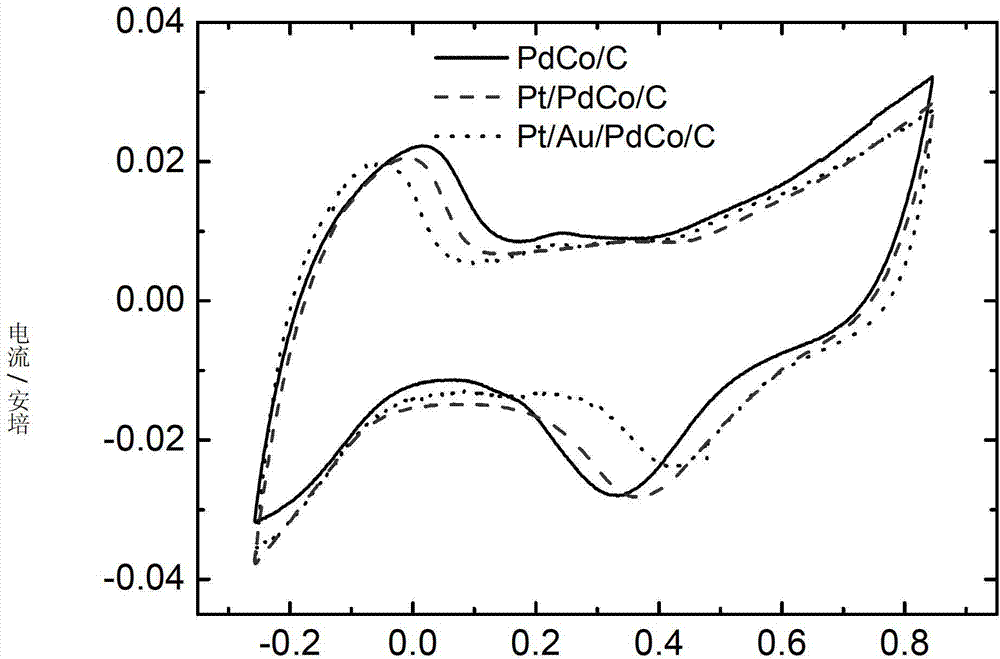

Gas diffusion electrode carried with double-shell core-shell catalyst and preparation and application thereof

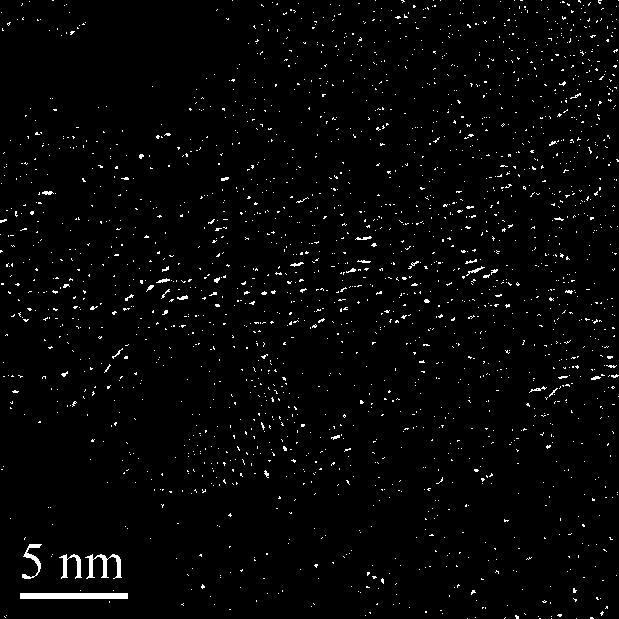

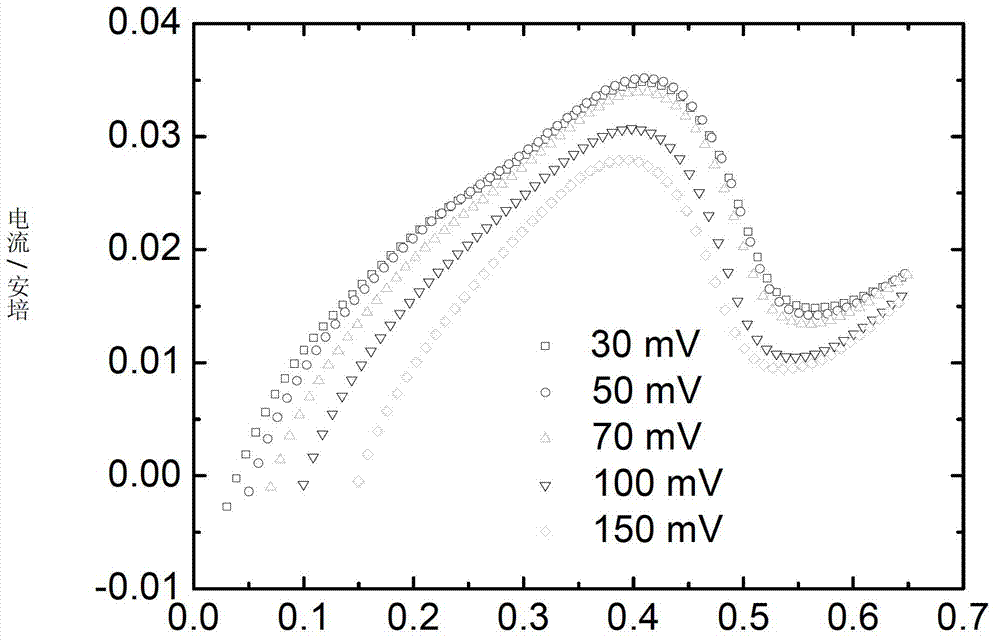

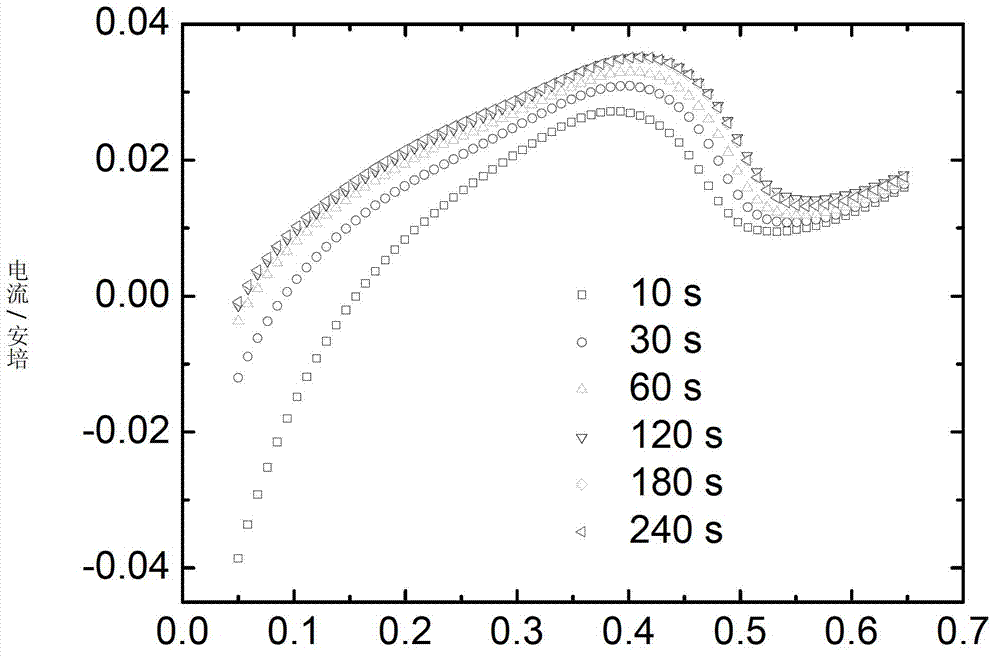

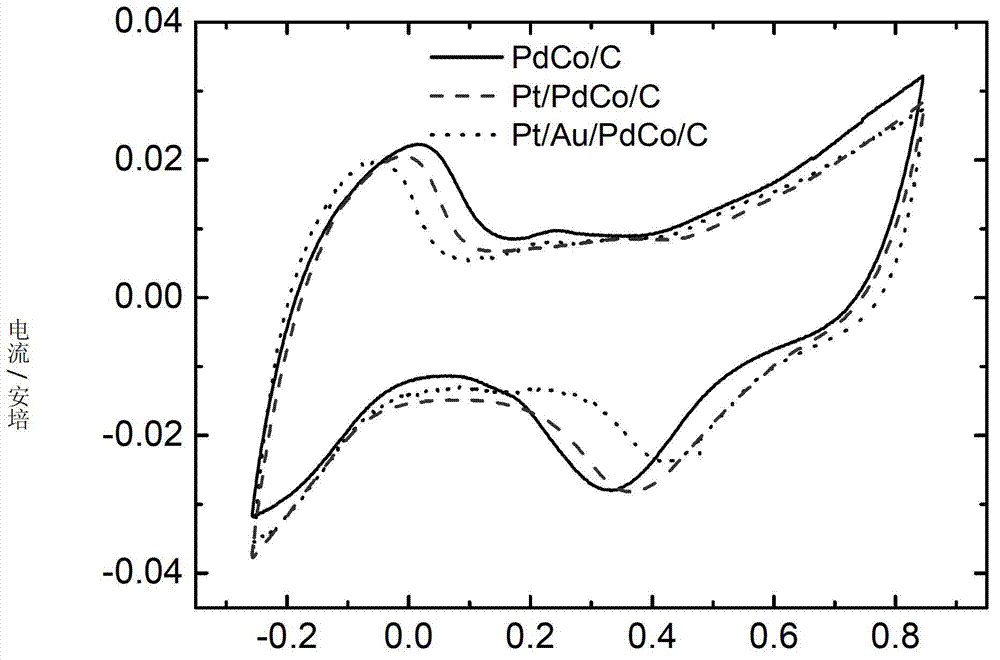

A gas diffusion electrode carried with a double-shell core-shell catalyst consists of a gas diffusion layer and a core-shell catalyst layer obtained on the gas diffusion layer in situ. A catalyst in the catalyst layer is the double-shell core-shell catalyst using a carbon-supported Pd alloy catalyst as a core, using Pt located on the surface as an outer shell and using Au located between the Pt shell and an alloying inner shell. A preparation method comprises three steps of (1) preparing the gas diffusion layer, (2) preparing the inner shell of the Pd alloy catalyst and (3) preparing the core-shell catalyst layer. When the gas diffusion electrode serves as a gas diffusion cathode for a metal air fuel cell, a proton exchange membrane fuel cell and a direct liquid fuel cell, the gas diffusion electrode has the advantages of being low in precious metal carrying capacity, high in utilization ratio, good in stability and the like, can remarkably reduce the fuel cell cost and is easily produced in a batch mode. In addition, the preparation method is simple and easy to operate.

Owner:中科军联(张家港)新能源科技有限公司

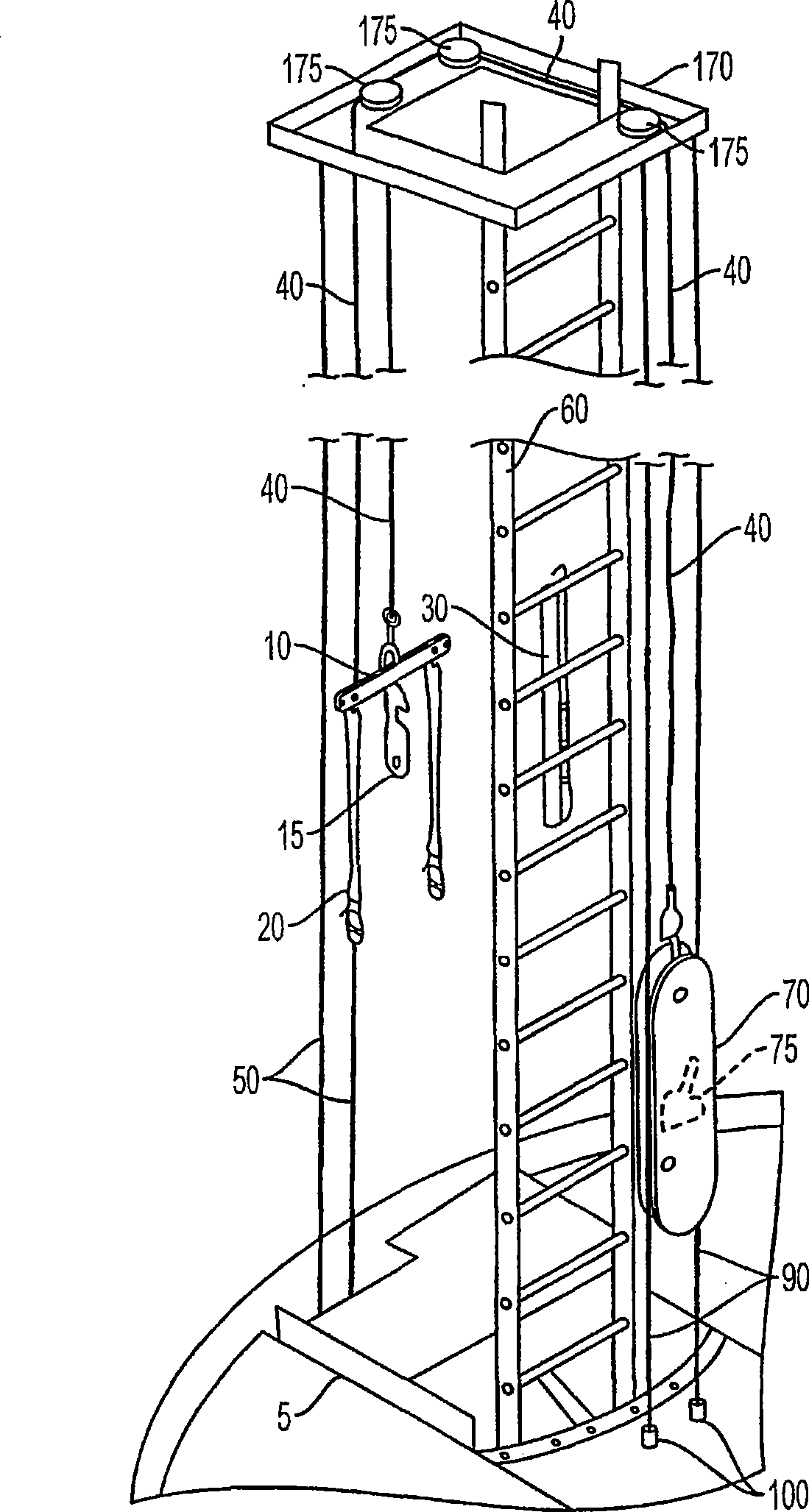

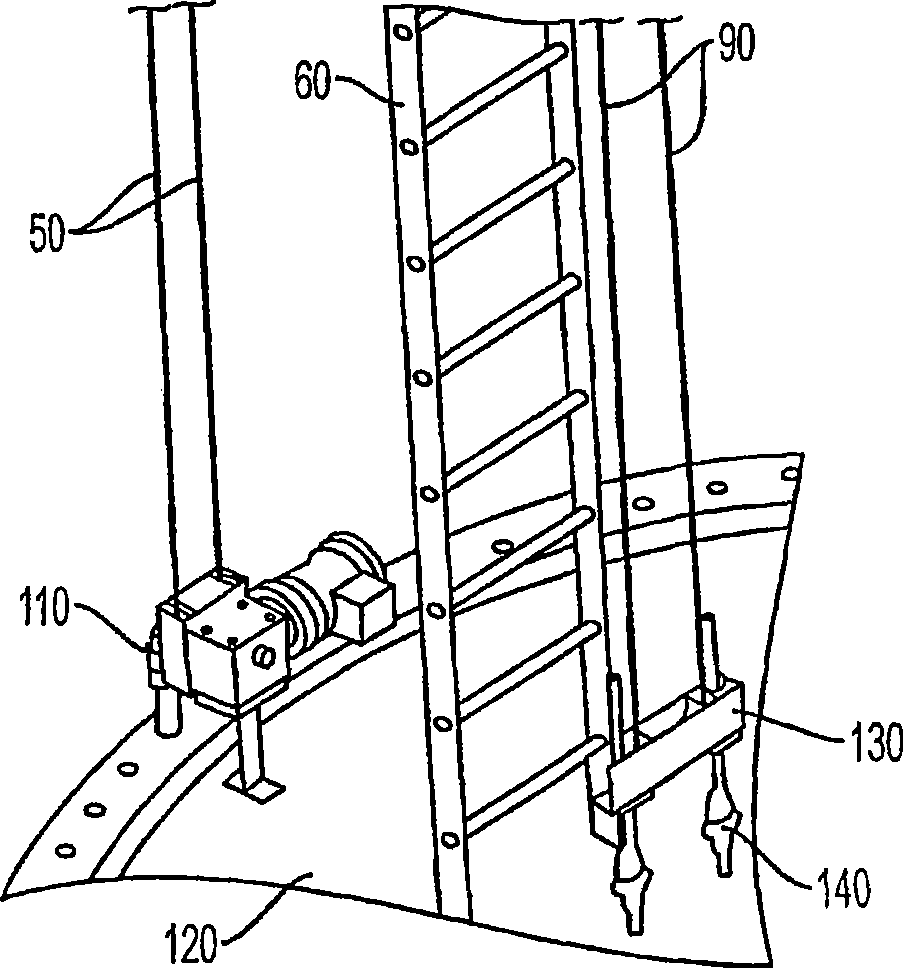

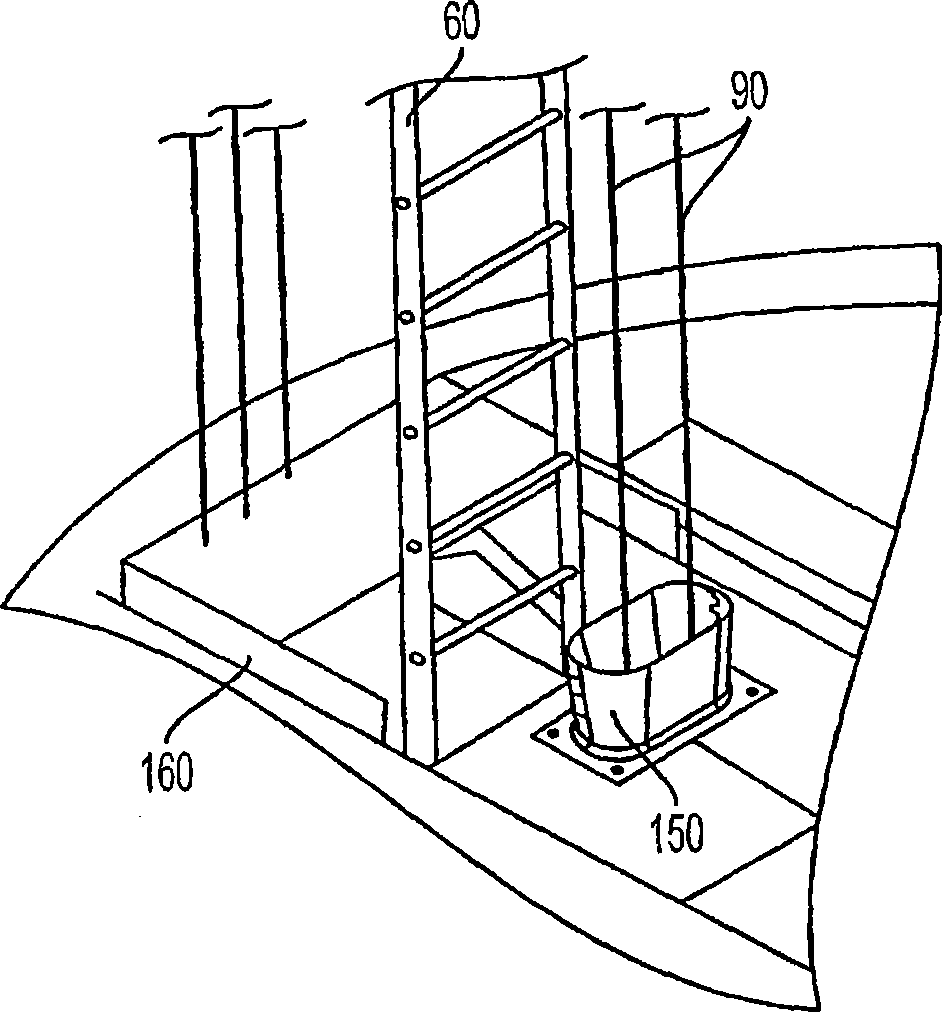

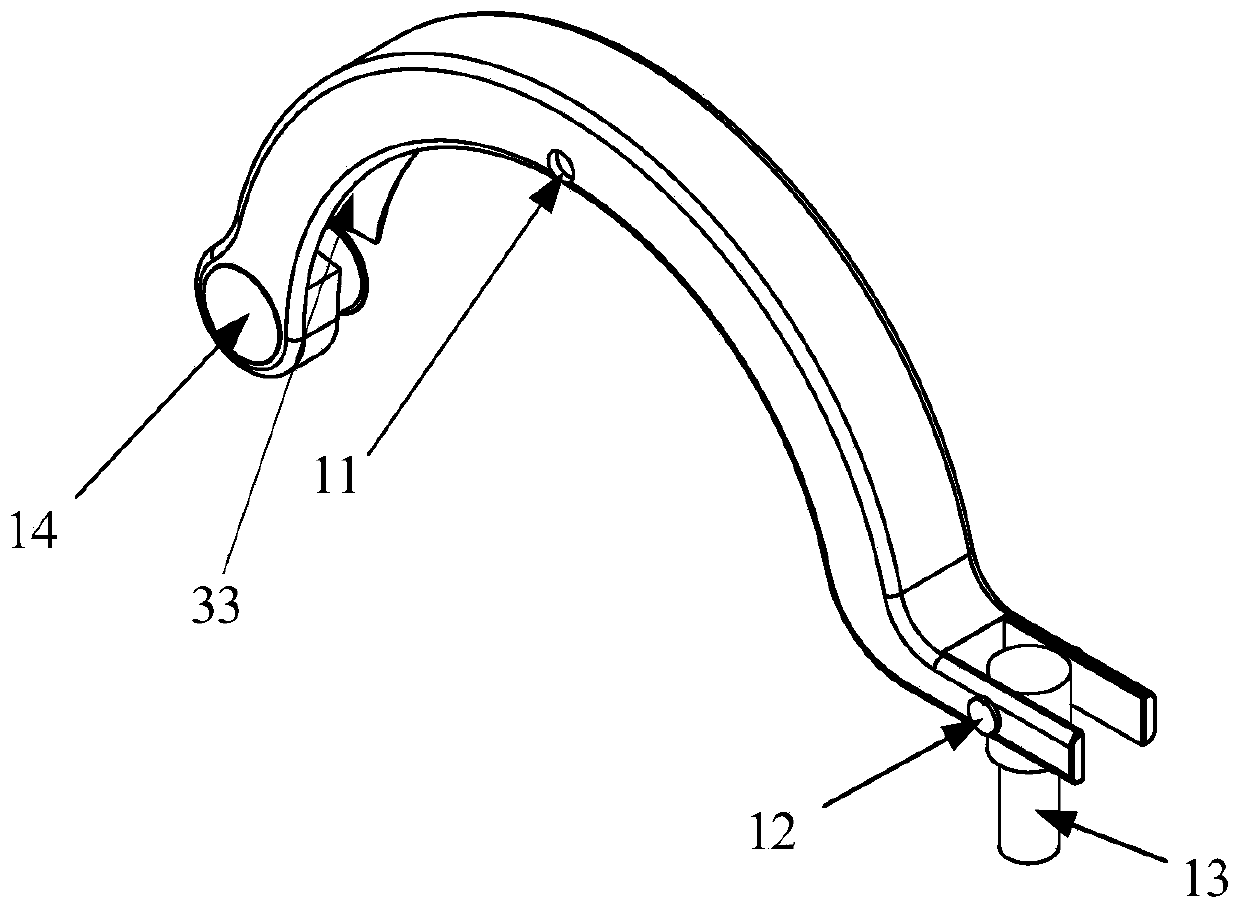

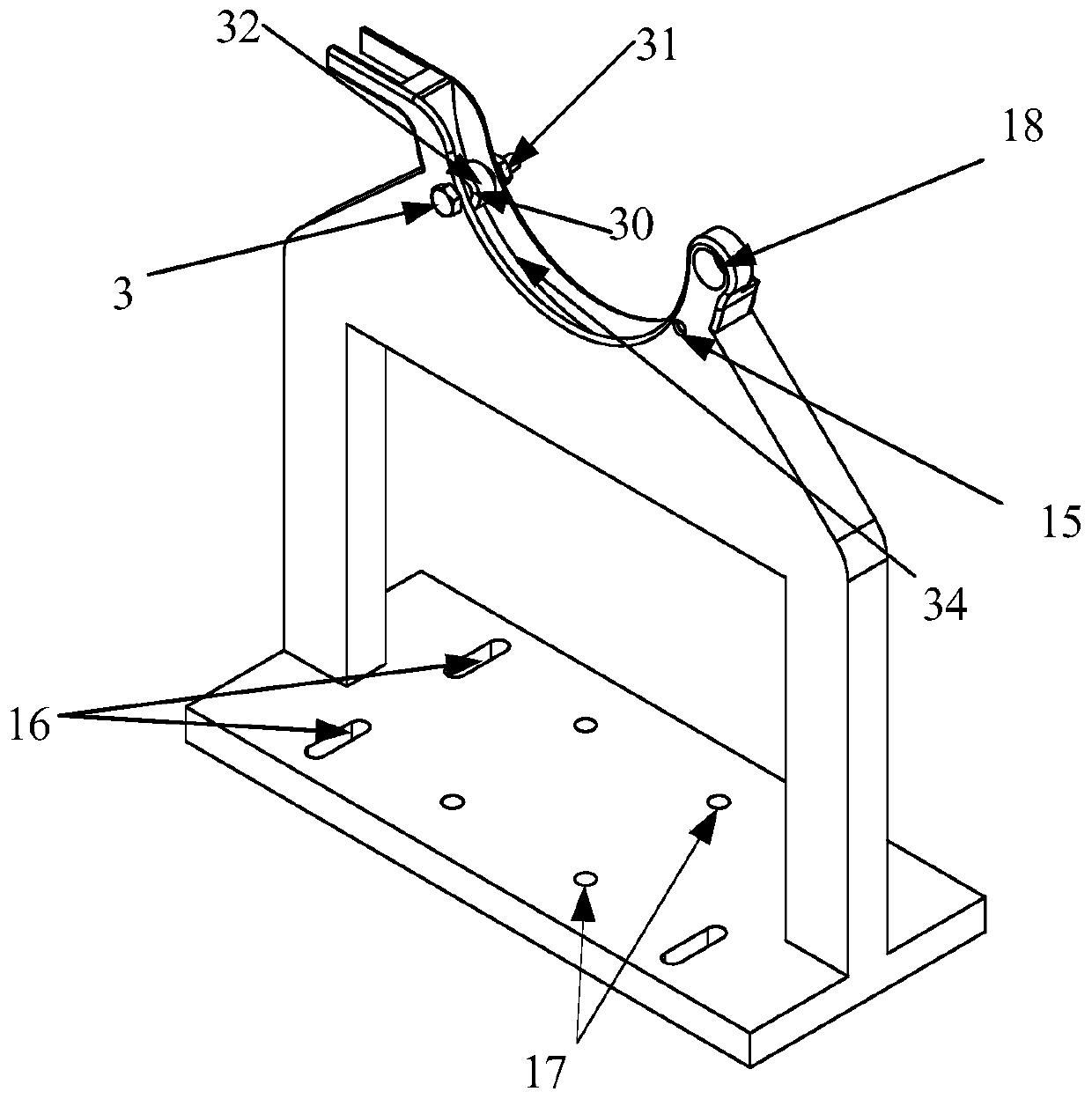

Climbing assistant device

A climbing assistant device comprises a connecting component, a yoke, a weight counterbalance and a stabilizer, wherein the connecting component is arranged on the predetermined position of the structure to be climbed, the yoke is capable of being connected to the human body, the weight counterbalance is connected to the yoke by a cable passing through a block system, and the stabilizer is used for stabilizing the weight counterbalance and preventing the rotation of the weight counterbalance. With the stabilizer, the weight counterbalance is in stability during the process of ascending and descending, and in control for the load thereof.

Owner:TOWER LOGISTICS

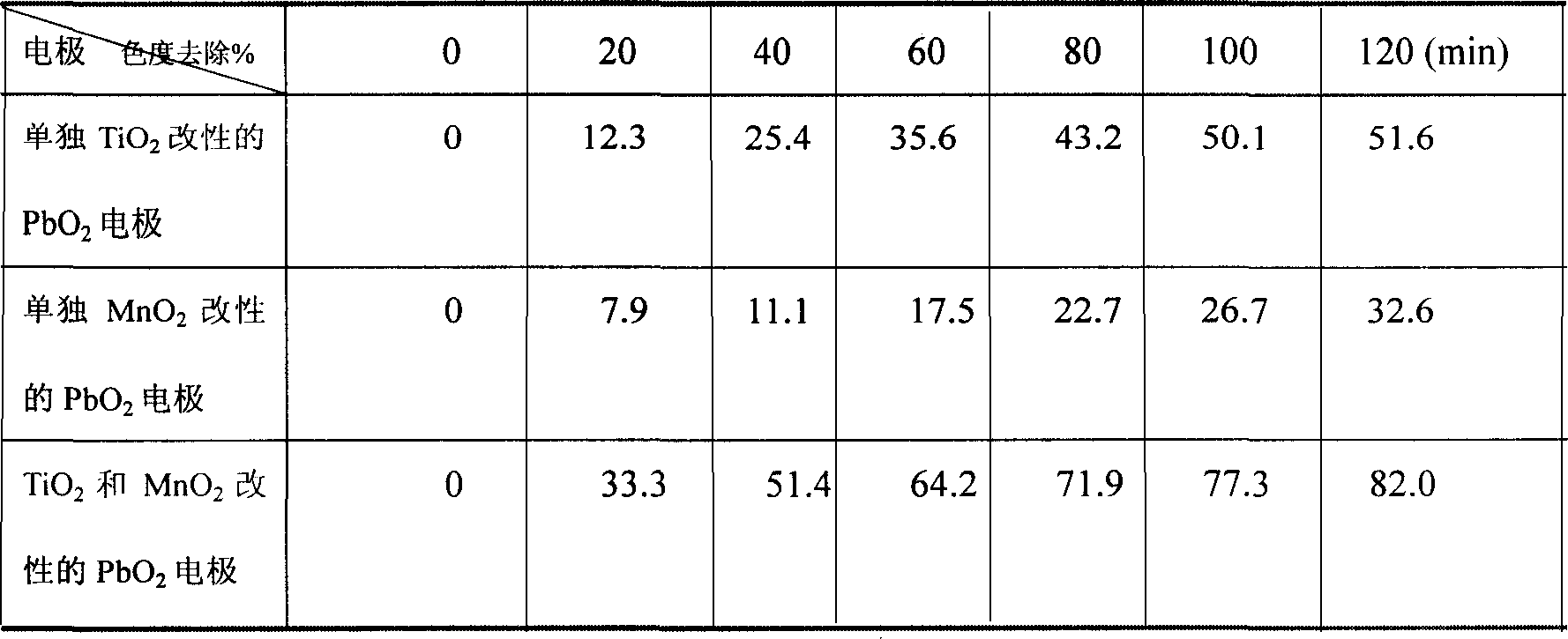

Electrode modified method for increasing degradation efficiency of PbO2 electrode

InactiveCN101058889ARaw materials are easy to getSave raw materialsWater/sewage treatment by irradiationEnergy based wastewater treatmentManganeseEngineering

The invention discloses a modifying method of electrode and application in the water disposal to improve PbO2 electrode degrading efficiency modified by TiO2 in the applying domain of water disposing technique, which is characterized by the following: adding particle to improve optical catalytic activity of electrode such as MnO2 or manganese salt; obtaining TiO2 and co-modified PbO2 electrode with other modifying materials; exerting external pressure to remove and mineralize organic pollution effectively.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

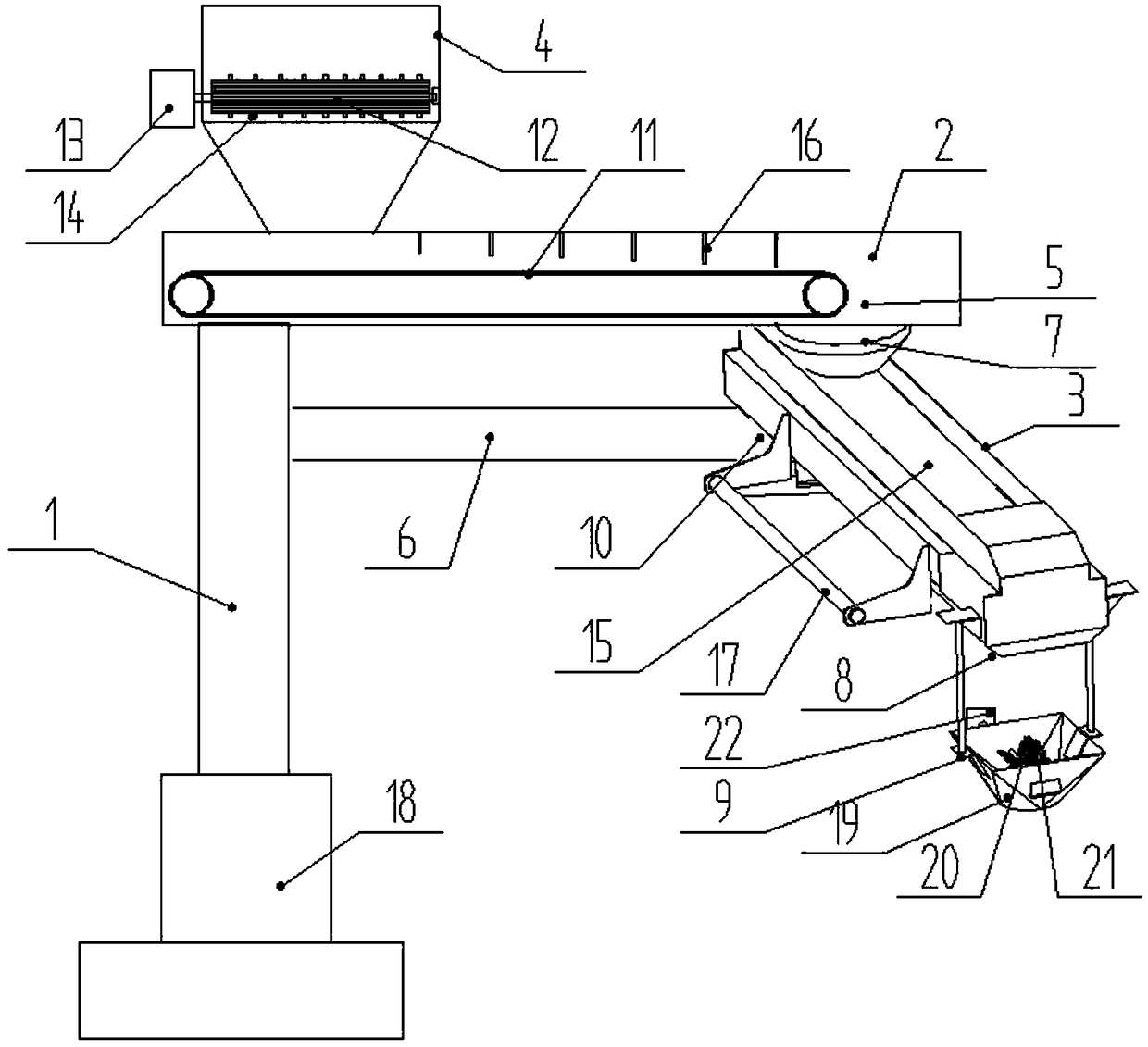

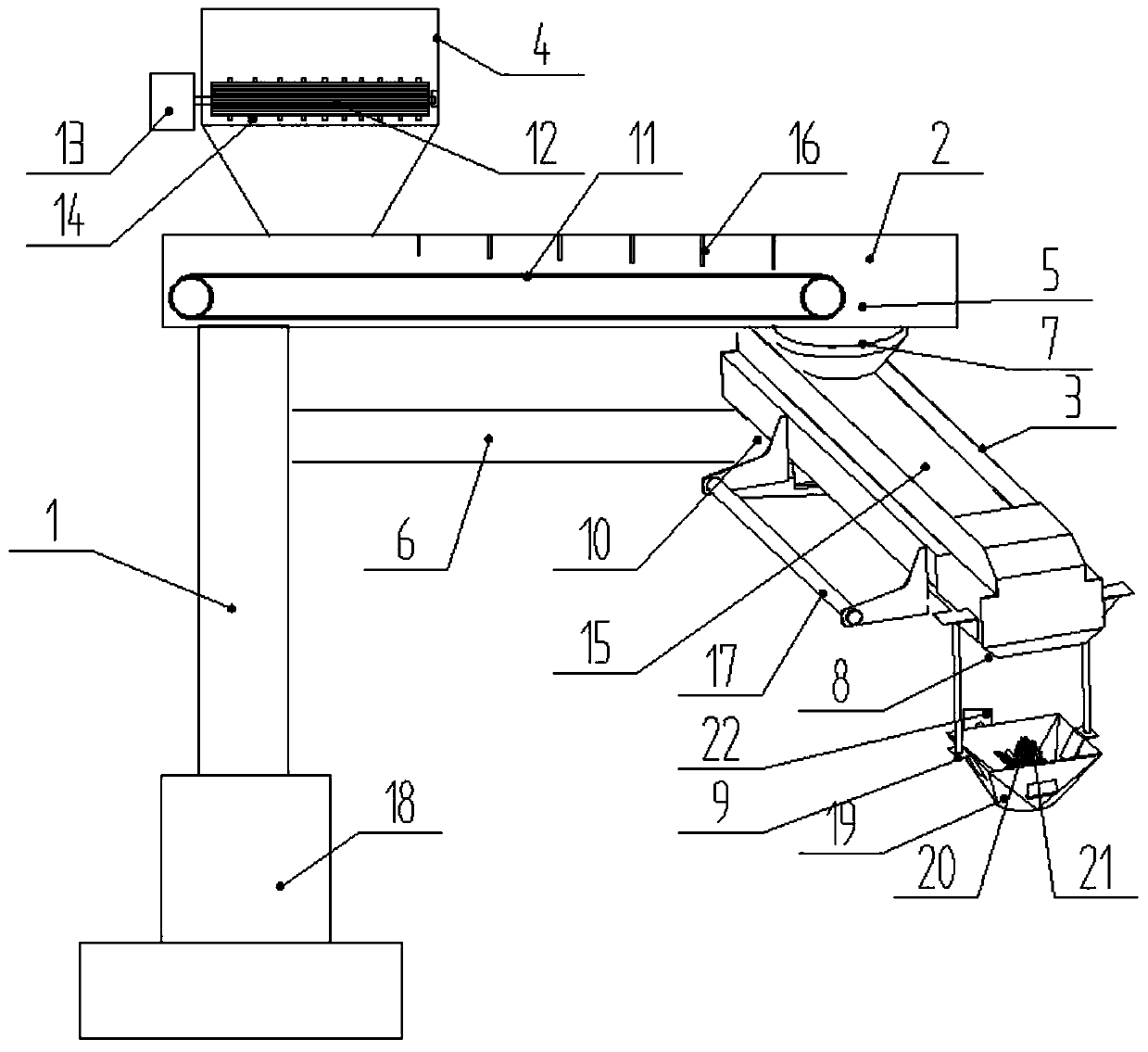

Steel fiber feeding and dispersing device and dispersing method

ActiveCN108858789ANo cloggingEvenly dispersedPretreatment controlSold ingredients supply apparatusFiberRocker arm

The invention discloses a steel fiber feeding and dispersing device and a dispersing method. A conveyor belt is arranged in a steel fiber conveying and dispersing arm, and the bottom surface of one end of the steel fiber conveying and dispersing arm is arranged at the upper end of a dispersing support column; a dispersing hopper is arranged on the end head of the steel fiber conveying and dispersing arm, and a discharge port is formed in the bottom surface of the other end of the steel fiber conveying and dispersing arm; a blanking cage is arranged in the dispersing hopper, and the blanking cage is driven by a blanking cage motor arranged outside the dispersing hopper to rotate; scrapping rake teeth are arranged on cage ribs of the blanking cage in disorder, the blanking cage continuouslyrotates, the steel fibers stacked at the upper part of the blanking cage are continuously racked off by the scraping rake teeth, and the dropped steel fibers are dispersed on the conveyor belt throughthe blanking cage; a rotary rocker arm support rack is arranged the dispersing support column corresponding to the lower part of the steel fiber conveying and dispersing arm, and the bottom surface of one end of a steel fiber rotary rocker arm is arranged at the outer end part of the rotary rocker arm support rack; a steel fiber receiving hopper is arranged on the end head of the steel fiber rotary rocker arm.

Owner:成都东蓝星新材料有限公司

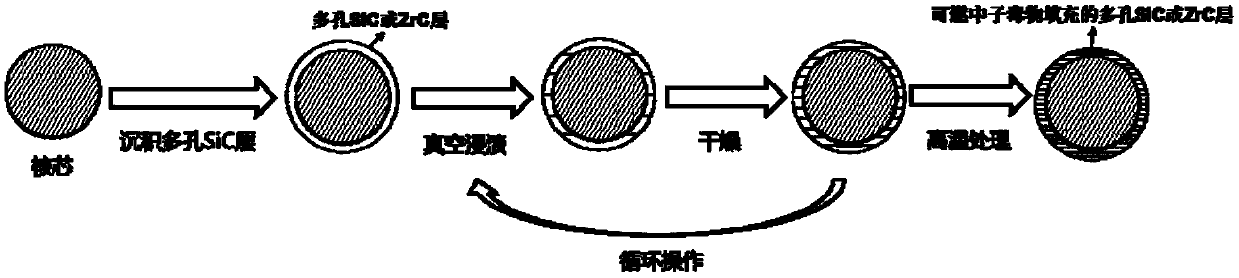

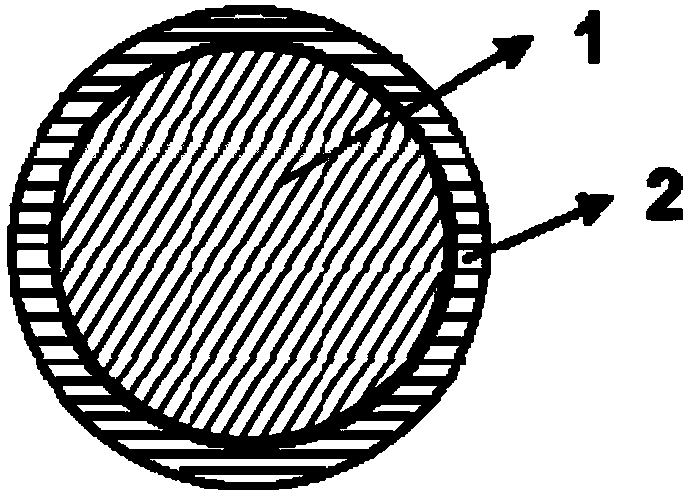

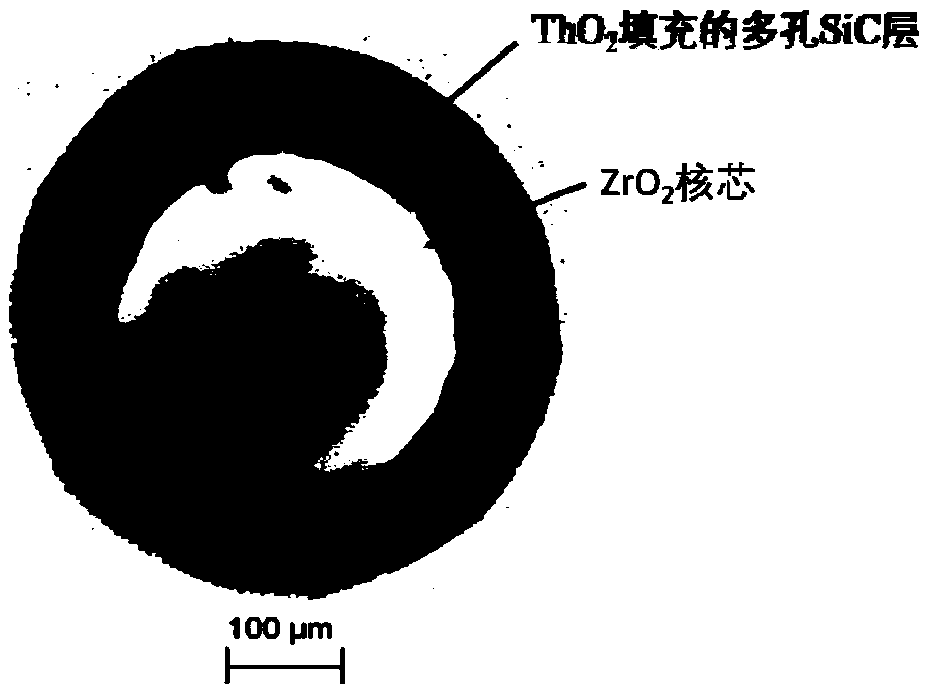

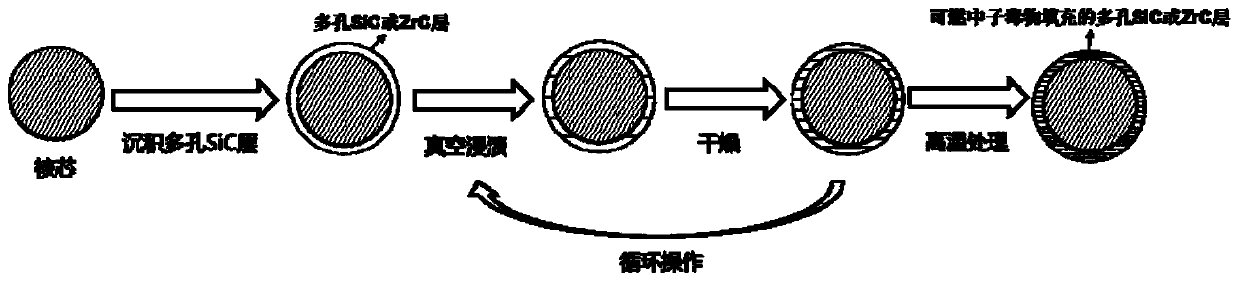

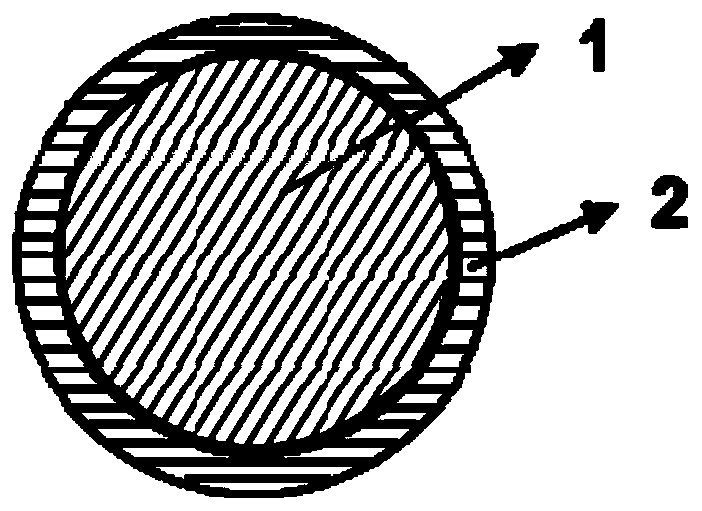

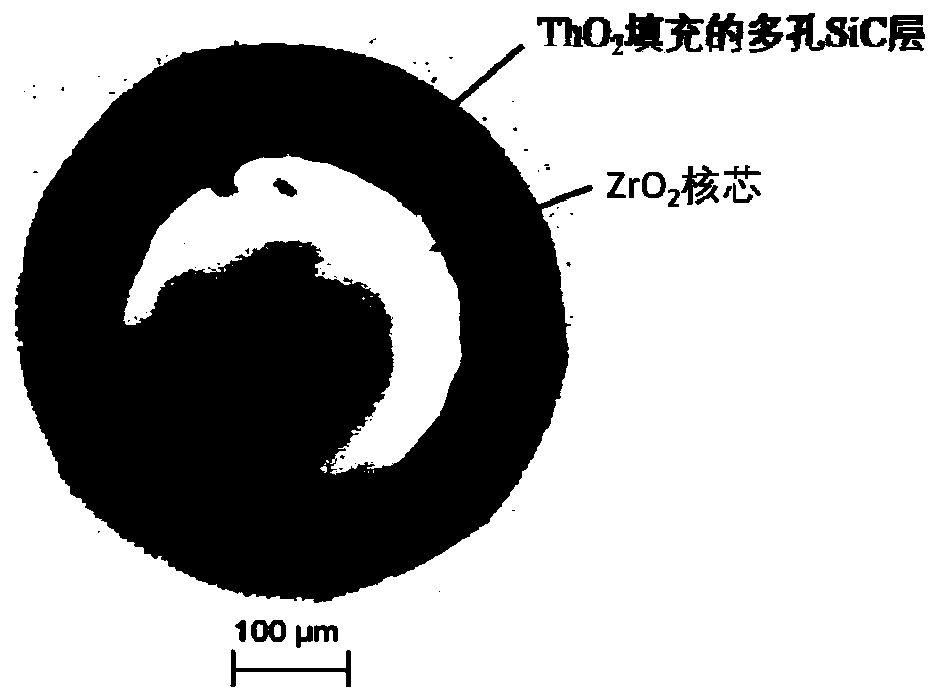

Method for preparing fuel particles and core-shell fuel particles prepared by using method

ActiveCN109545414AImprove securityImprove economyNuclear energy generationReactors manufactureNeutron poisonThorium oxide

The invention relates to a method for preparing fuel particles. The method comprises the steps: supplying a spherical core, performing formation of a porous silicon carbide layer or a zirconium carbide layer on the core through chemical vapor deposition so as to obtain porous silicon carbide layer / zirconium carbide layer-coated particles, soaking the porous silicon carbide layer / zirconium carbidelayer-coated particles in an active liquid for vacuum impregnation so as to obtain compound-filled porous silicon carbide layer / zirconium carbide layer-coated particles, and decomposing compounds which are filled in the compound-filled porous silicon carbide layer / zirconium carbide layer-coated particles so as to form combustible neutron-poison oxides or thorium oxide and finally obtain the fuel particles. The invention also provides core-shell fuel particles prepared by using the method. The fuel particle safety which is stack safety is improved through coating of the silicon carbide layer orthe zirconium carbide layer outside the core, and meanwhile the stack economy can be improved through the combustible neutron-poison oxides or thorium oxide filled in the silicon carbide layer or zirconium carbide layer.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

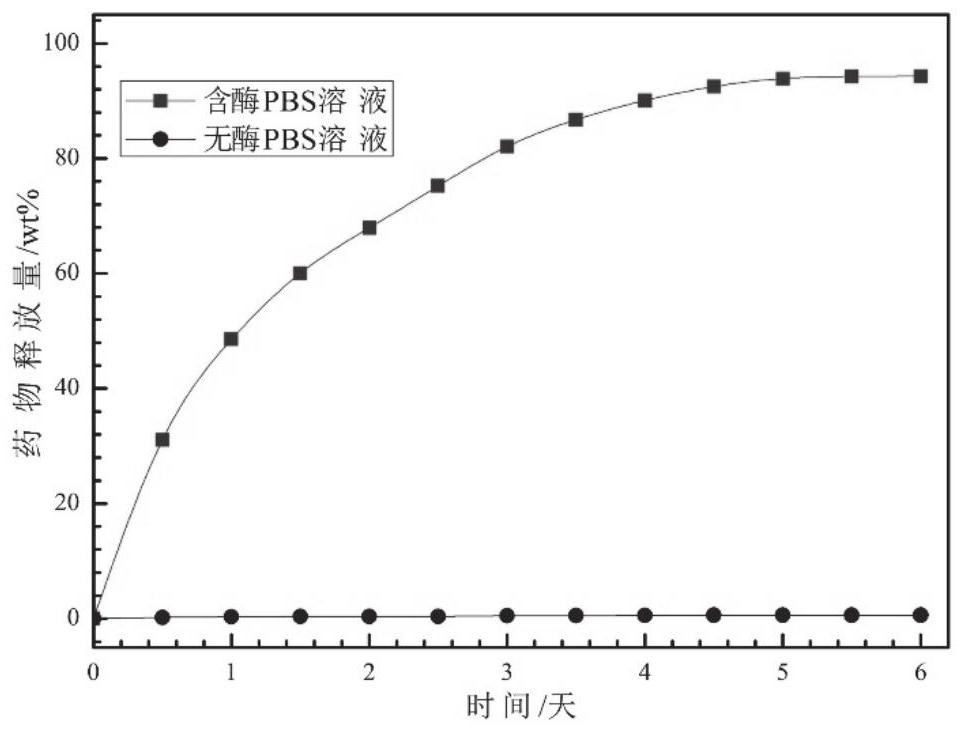

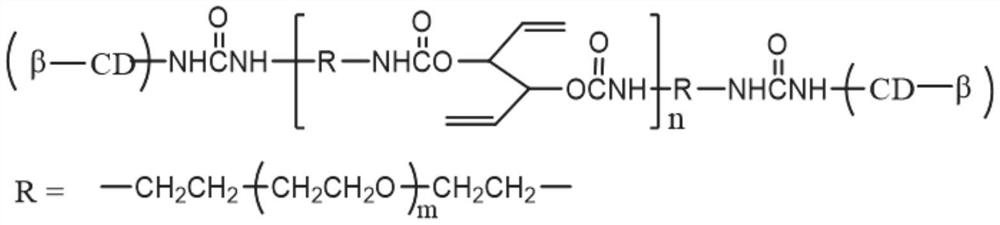

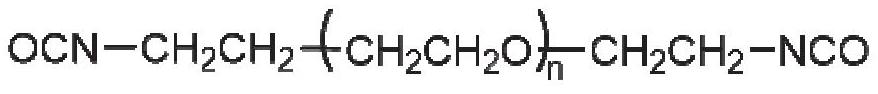

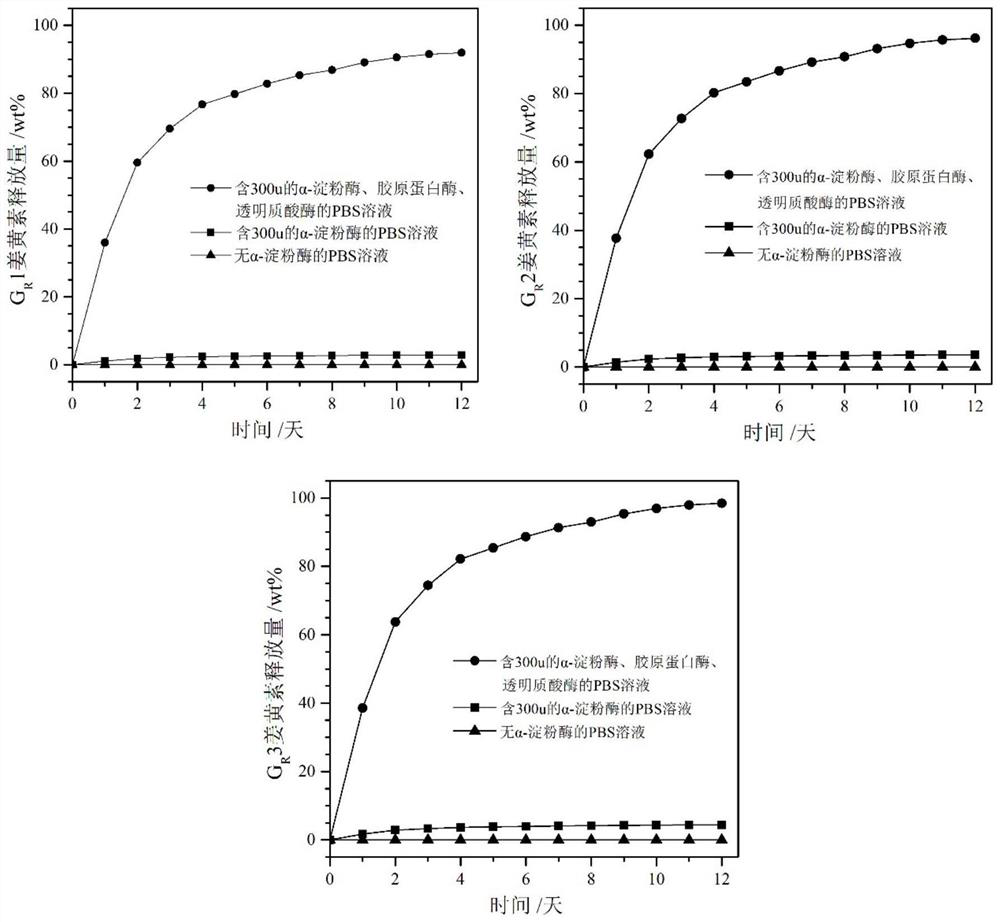

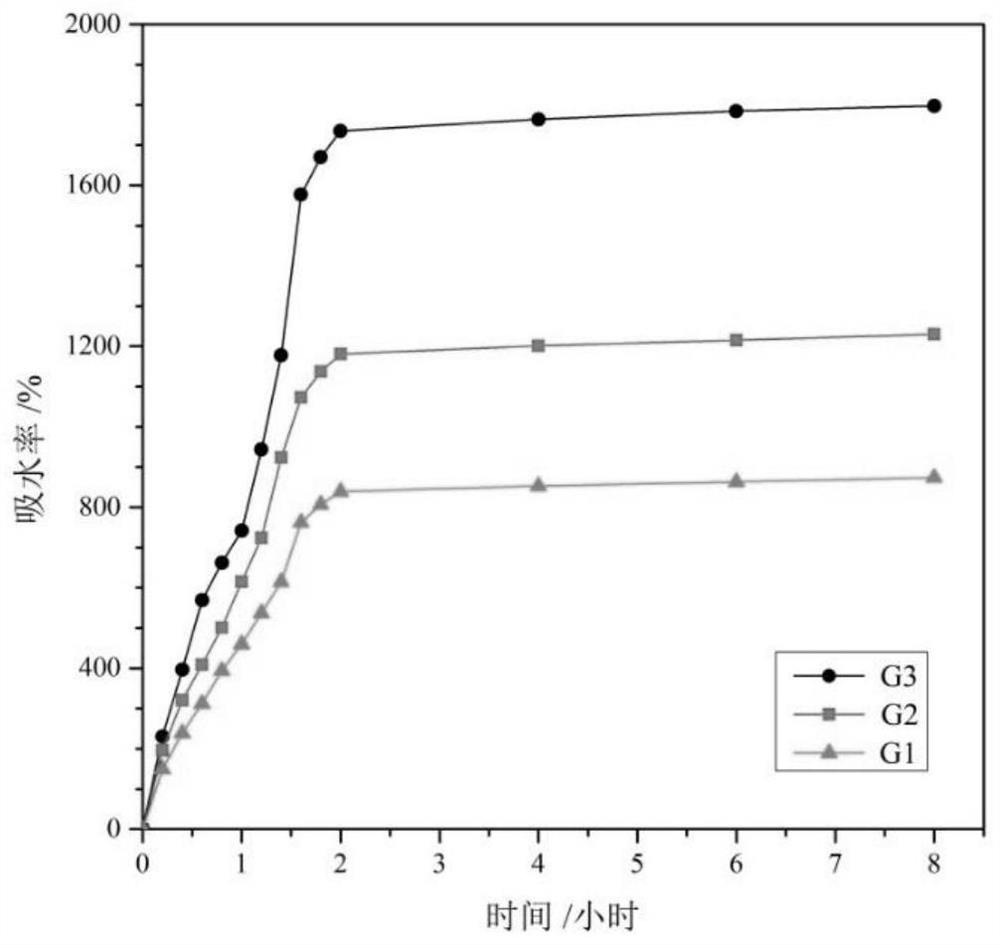

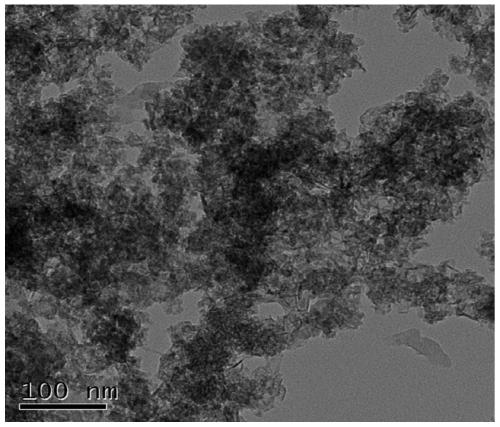

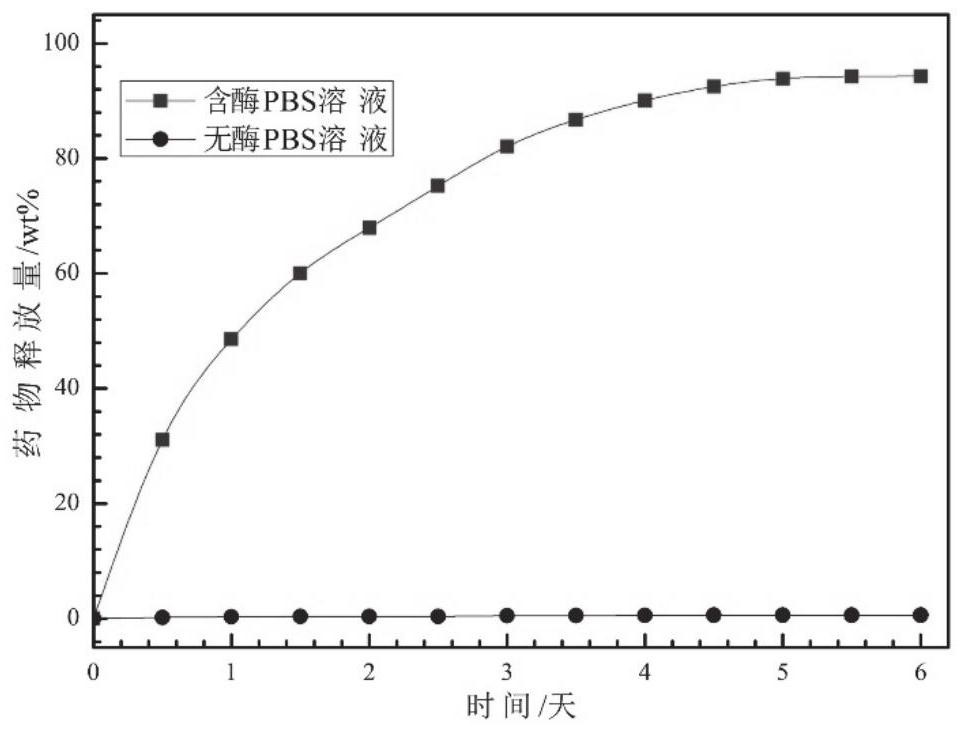

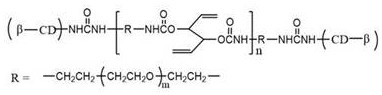

Hydrogel capable of loading high-hydrophobicity drug as well as preparation method and application of hydrogel

ActiveCN113416292AGood biocompatibilityGood physiological acceptabilityOrganic active ingredientsAerosol deliveryPolymer scienceSide chain

The invention provides hydrogel capable of loading a high-hydrophobicity drug as well as a preparation method and application of the hydrogel, which belongs to the technical field of preparation of high polymer materials. The preparation method comprises the following steps of firstly, preparing cyclodextrin-terminated polyurethane (DPU) with a side chain containing double bonds, and carrying out click chemical crosslinking on a multi-sulfhydryl compound and the double bonds to form the polyurethane hydrogel. The inner cavity of cyclodextrin is hydrophobic, the outer edge of the cyclodextrin is hydrophilic, and a hydrophobic binding site can be provided, so that the cyclodextrin molecular cavity in the polyurethane hydrogel can be subjected to non-covalent binding with a high-hydrophobicity drug, the loading of the high-hydrophobicity drug is realized, the gel is very stable in vitro, and under the action of an in-vivo enzyme, the cyclodextrin polysaccharide is gradually degraded, so that the combined medicine is released, the hydrogel capable of loading the high-hydrophobicity drug is successfully prepared, and the hydrogel has a good practical application value.

Owner:CHANGSHA JINGYI PHARM TECH CO LTD

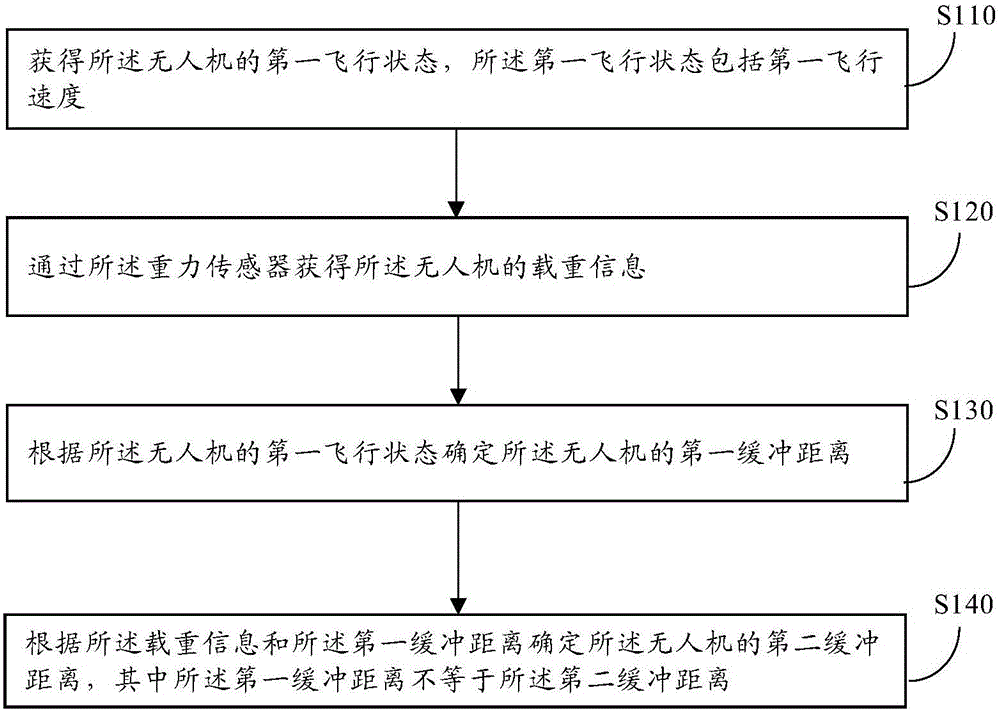

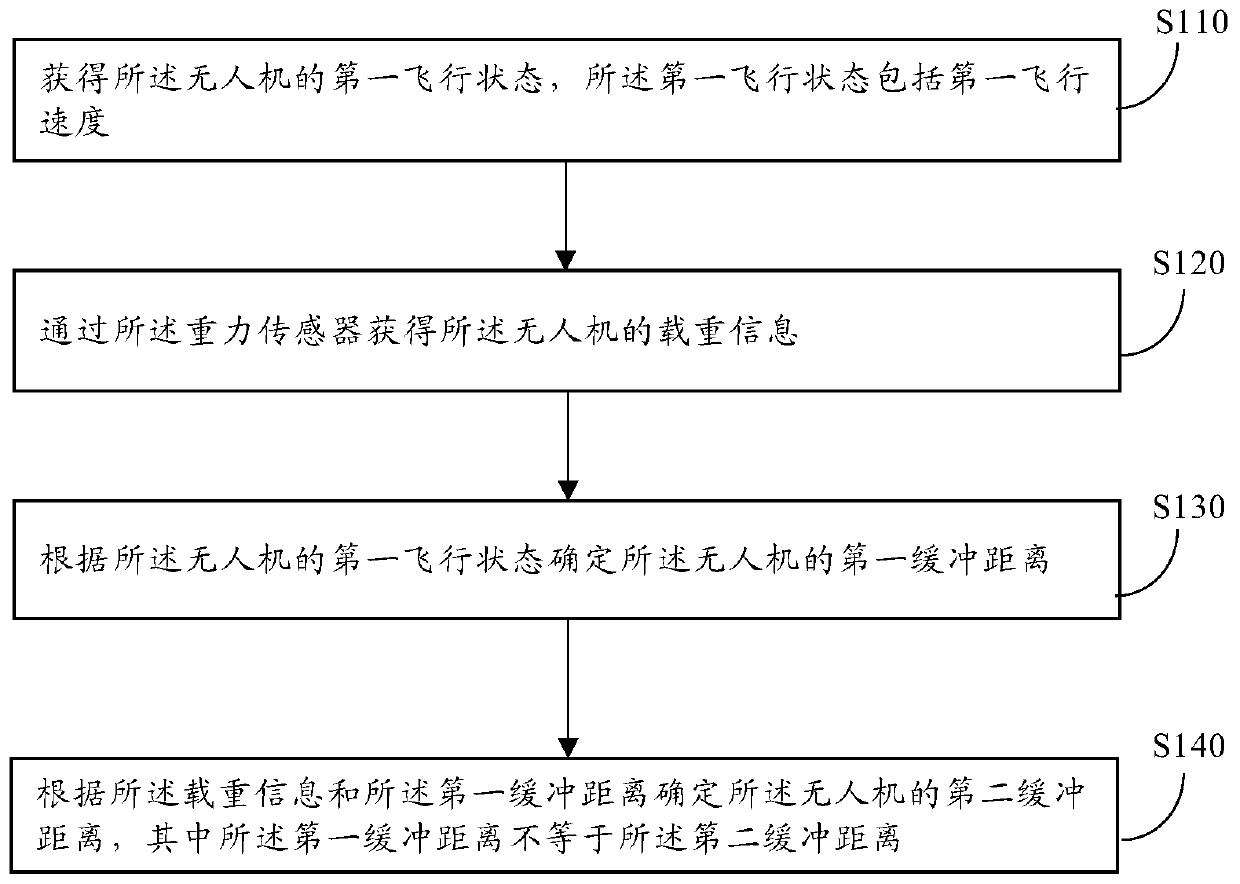

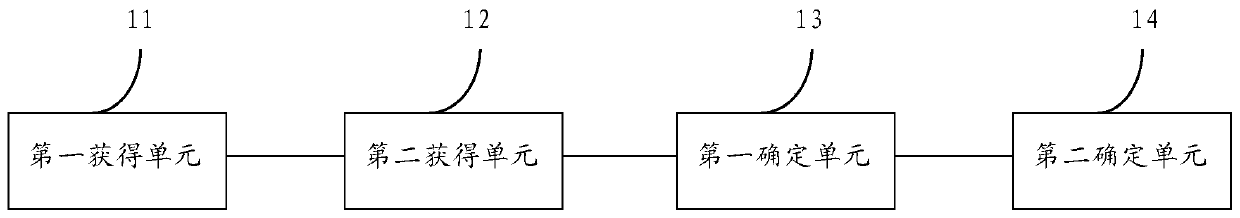

Flight control method and device of unmanned aerial vehicle

InactiveCN106681314AEffective flight controlFlight control effective controlControl safety arrangementsPosition/course control in three dimensionsUncrewed vehicleFlight speed

Owner:EWATT TECH CO LTD

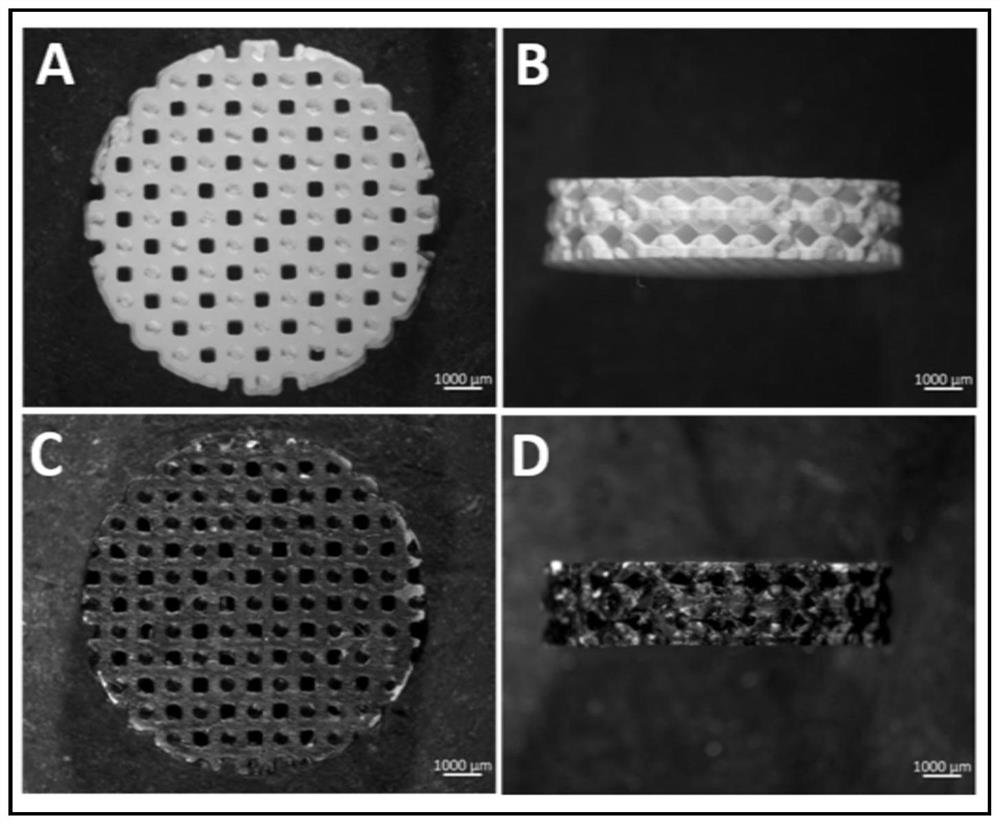

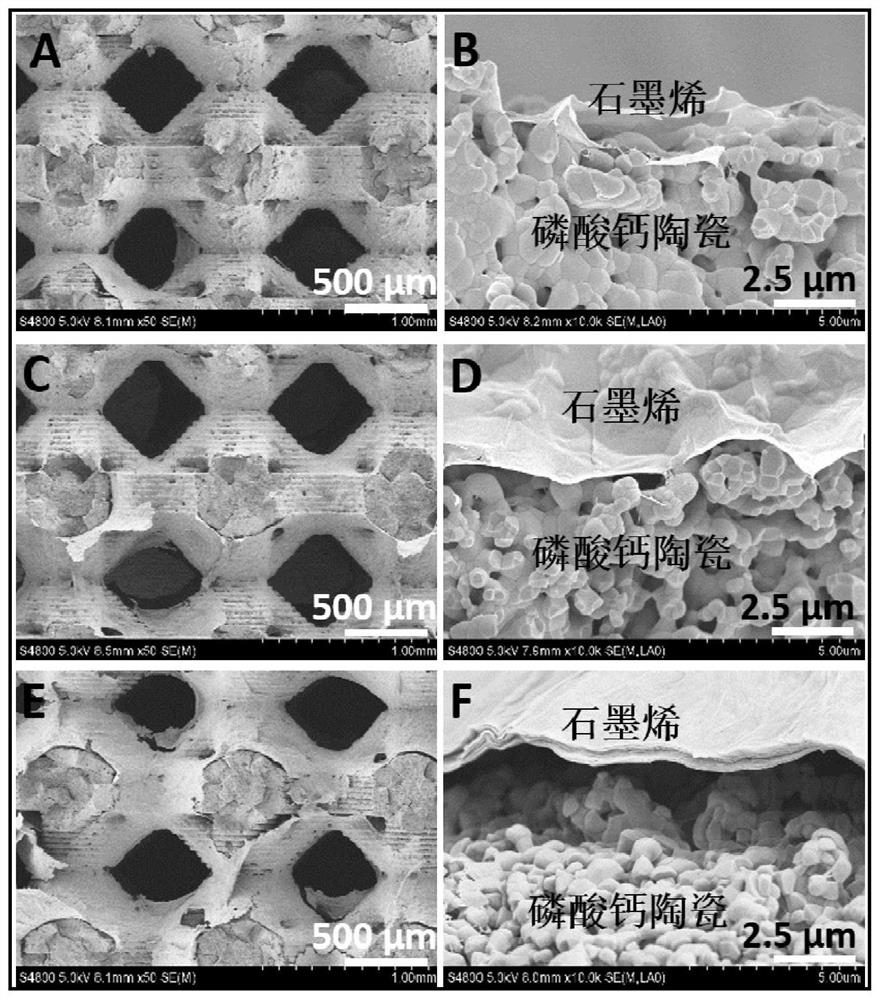

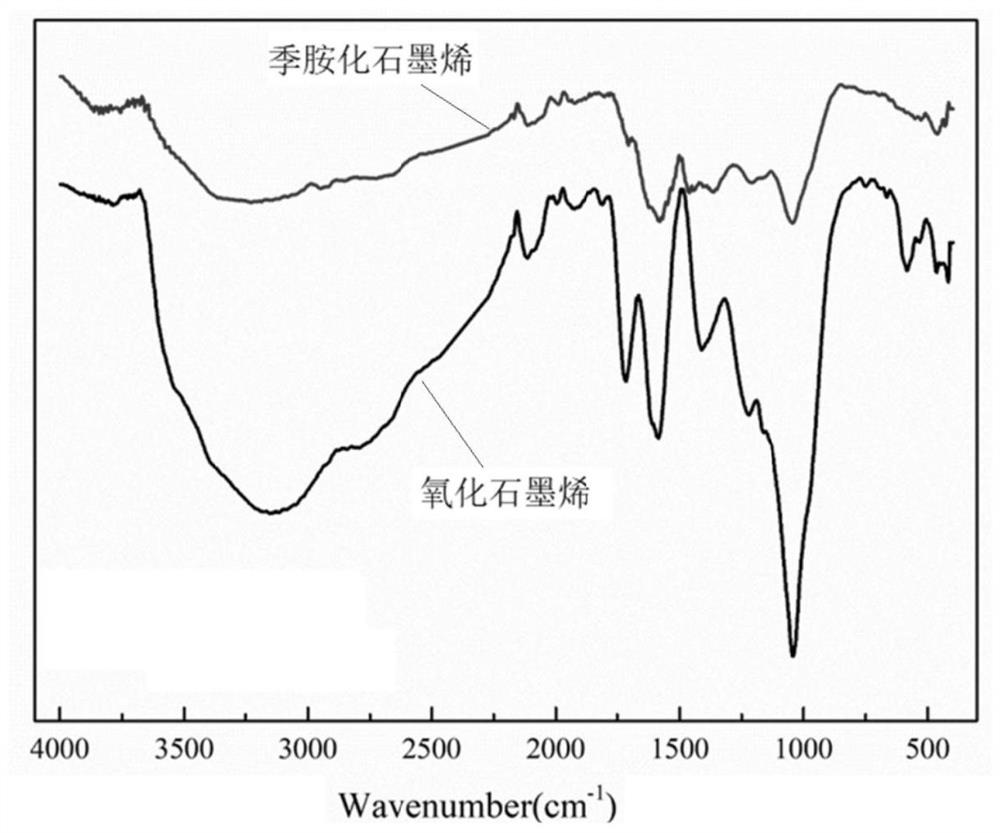

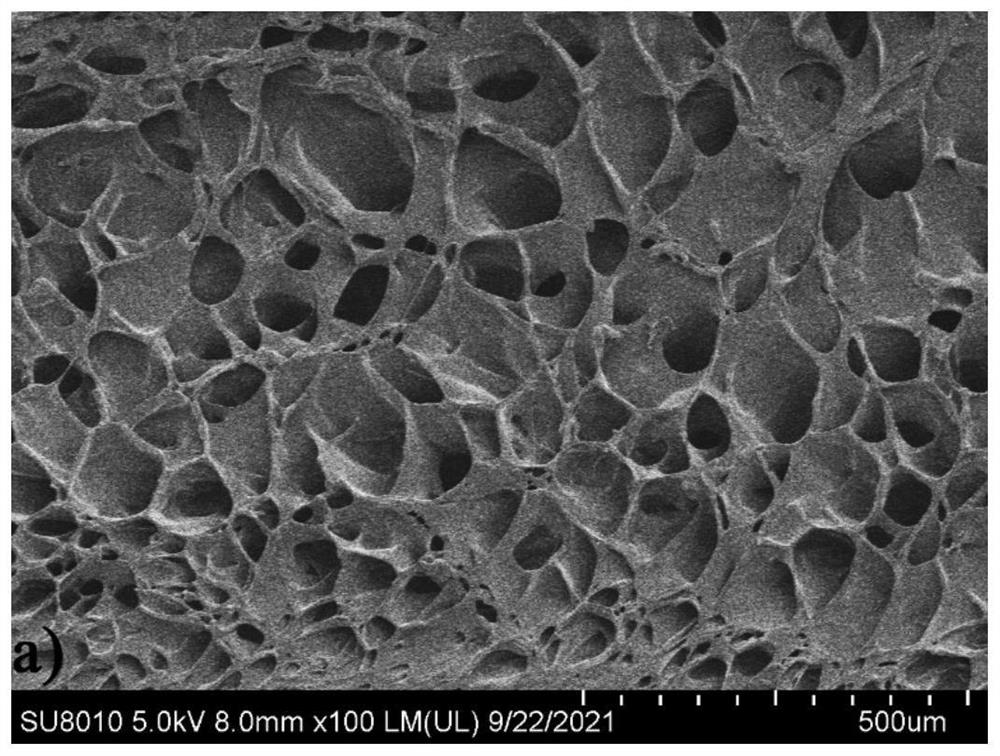

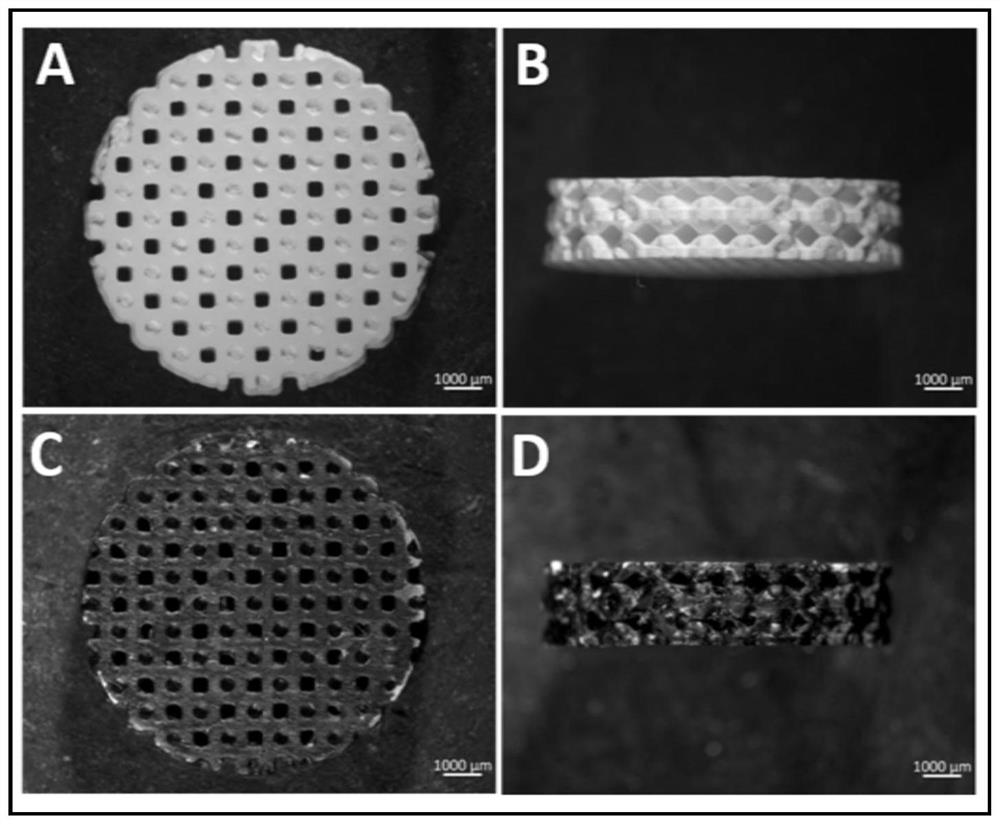

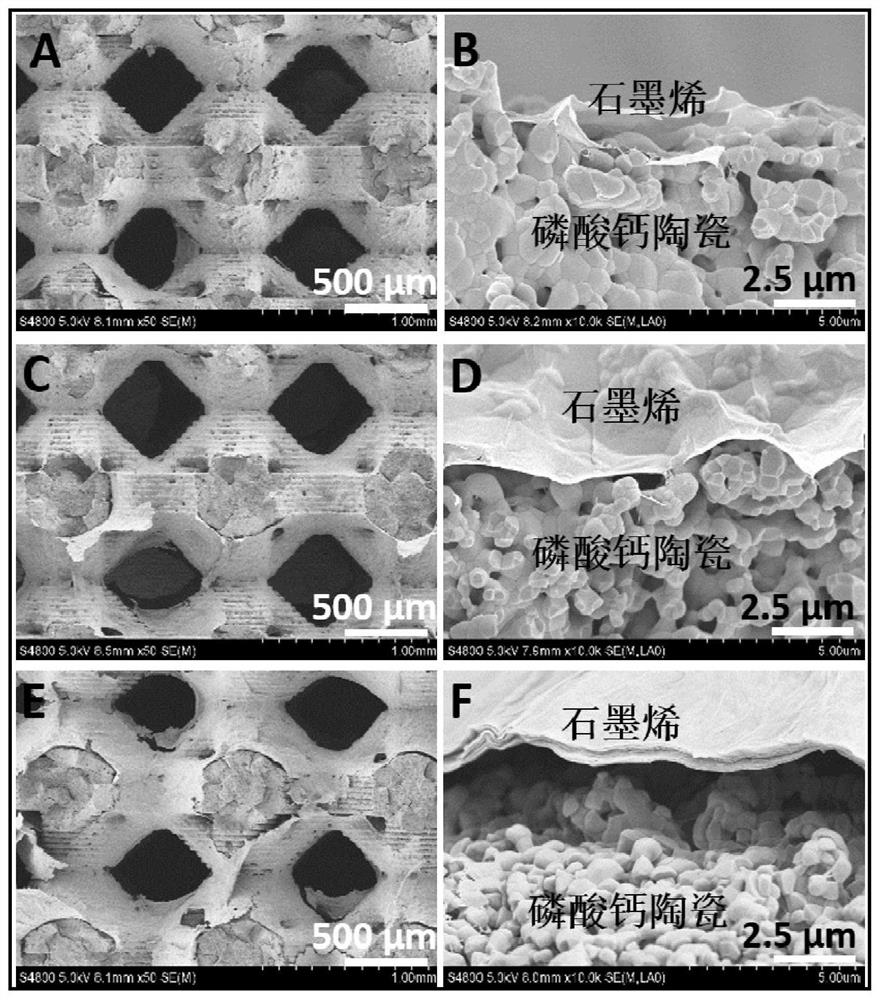

Graphene/calcium phosphate ceramic composite scaffold with antibacterial function and preparation method thereof

ActiveCN112745142AImprove biological performanceLight and heat synergistic antibacterial performance is goodCoatingsCeramicwareCalcium biphosphateCeramic composite

The invention belongs to the technical field of biomedical materials, and discloses a graphene / calcium phosphate ceramic composite scaffold with an antibacterial function and a preparation method thereof. The preparation method comprises the following steps: placing porous calcium phosphate ceramic in a graphene-based material solution with a certain concentration, adsorbing graphene on the surface and in pores of the porous calcium phosphate ceramic through vacuum infusion, and drying to obtain the graphene / calcium phosphate ceramic composite scaffold. The graphene / calcium phosphate ceramic composite scaffold prepared by the method not only has good bone induction performance, but also has good antibacterial activity, and is expected to have a wide application prospect in clinical infectious bone defect regeneration and repair.

Owner:SICHUAN UNIV

Magnetic targeting hydrophobic drug carrier hydrogel as well as preparation method and application thereof

PendingCN114524950APlay a moisturizing rolePromote recoveryHydroxy compound active ingredientsAerosol deliveryCyclodextrinPharmaceutical Substances

The invention belongs to the field of high polymer material preparation, and relates to a magnetic targeting hydrophobic drug carrier hydrogel and a preparation method and application thereof.The preparation method comprises the steps that collagen is added into a mono-6-deoxy-ethylenediamine-beta-cyclodextrin solution, after dissolution, cooling is conducted, the collagen is mixed with a 4, 5-dehydrate-6 (n-acetylglucosamine)-oxidized hyaluronic acid solution, uniform mixing is conducted, and the magnetic targeting hydrophobic drug carrier hydrogel is obtained; and degassing, pouring into a mold, and standing to obtain the product. According to the drug-loaded hydrogel provided by the invention, the collagen and the hyaluronic acid are decomposed to generate small molecular products under the action of enzyme, the hyaluronic acid belongs to acidic mucopolysaccharide, the collagen belongs to protein, and the hyaluronic acid and the collagen can be degraded and absorbed by a human body in the presence of corresponding enzyme in the human body.

Owner:SHANDONG NORMAL UNIV

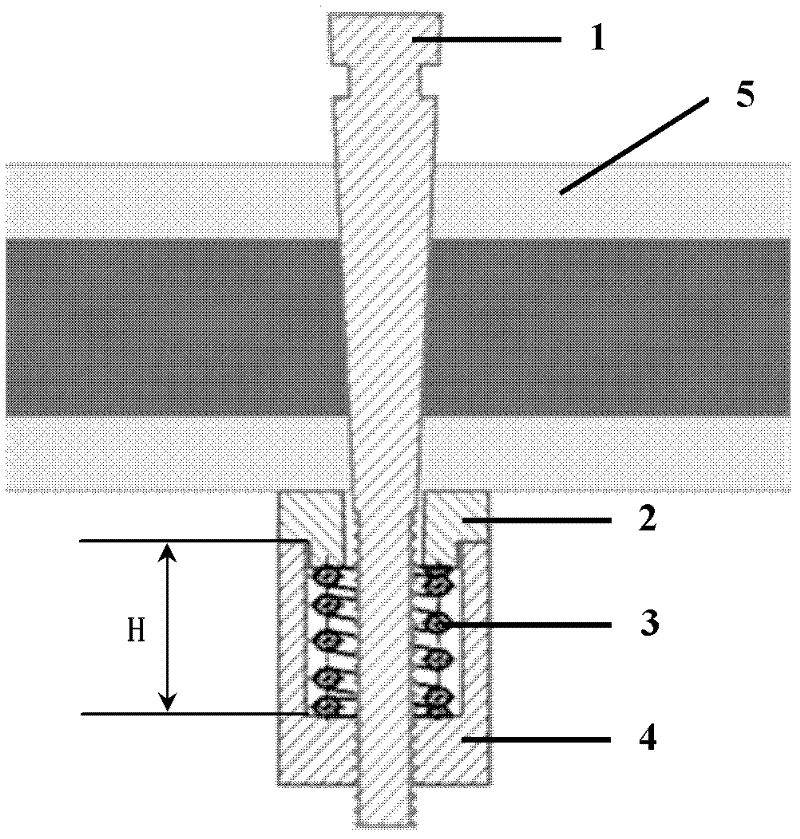

Built-in implantation loading method and built-in loading device for small laboratory animal

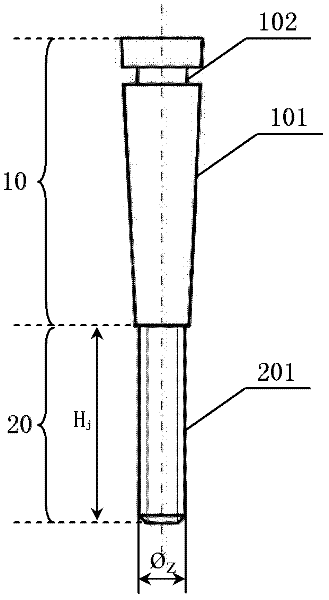

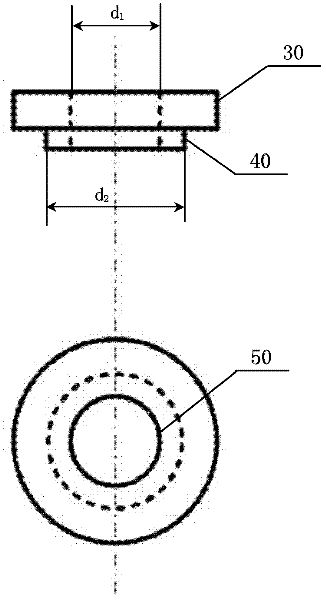

The invention discloses an endosteal implantation loading method and a built-in loading device for a small laboratory animal. The device consists of a matrix, a gasket, a spring and a position fixing cap. The matrix is divided into an integration section with taper and a fixing section with an external screw thread; the gasket is a step short shaft with a center hole; and the upper part of the position fixing cap is provided with a circular ring cylinder and the lower part of the position fixing cap is provided with a pentagonal prism with a screwed hole. During the experiment, the matrix is implanted into a backbone prepared hole from the outside, the integration section runs through the whole bone cavity, the fixing section protrudes from the inside and then the gasket, the spring and the position fixing cap are sequentially arranged on the fixing section, wherein the position fixing cap is in screw thread fit with the matrix body; and when the position fixing cap is screwed down, the spring needs to be compressed until the circular ring cylinder of the position fixing cap is gradually close to the step short shaft of the gasket to form a gapless embedded structure. Compared with the existing external frame-type loading method and device, the endosteal implantation loading method and the built-in loading device have the characteristic of generating a load amount required by the experiment by designing the deformation amount of the spring and have the advantages that the method and the device are accurate to load and are easy to control; the wound is small; and the device is difficult to interfere.

Owner:BEIHANG UNIV

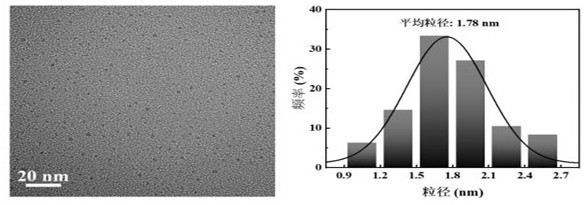

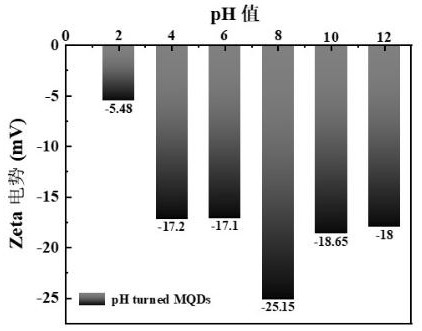

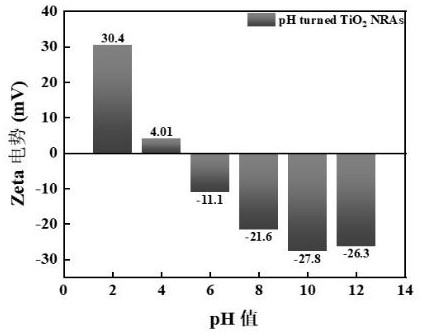

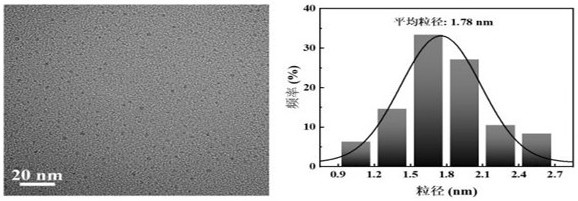

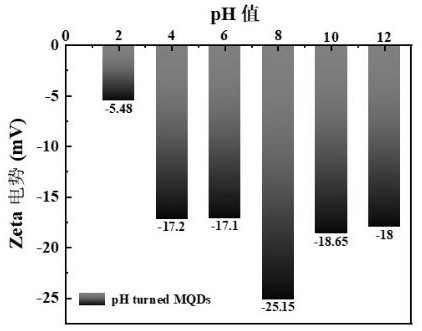

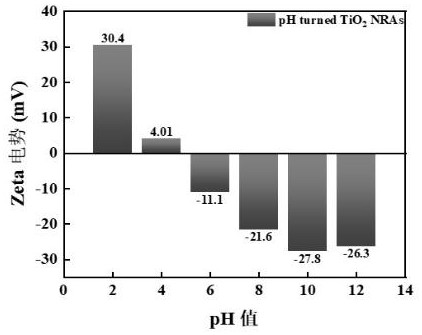

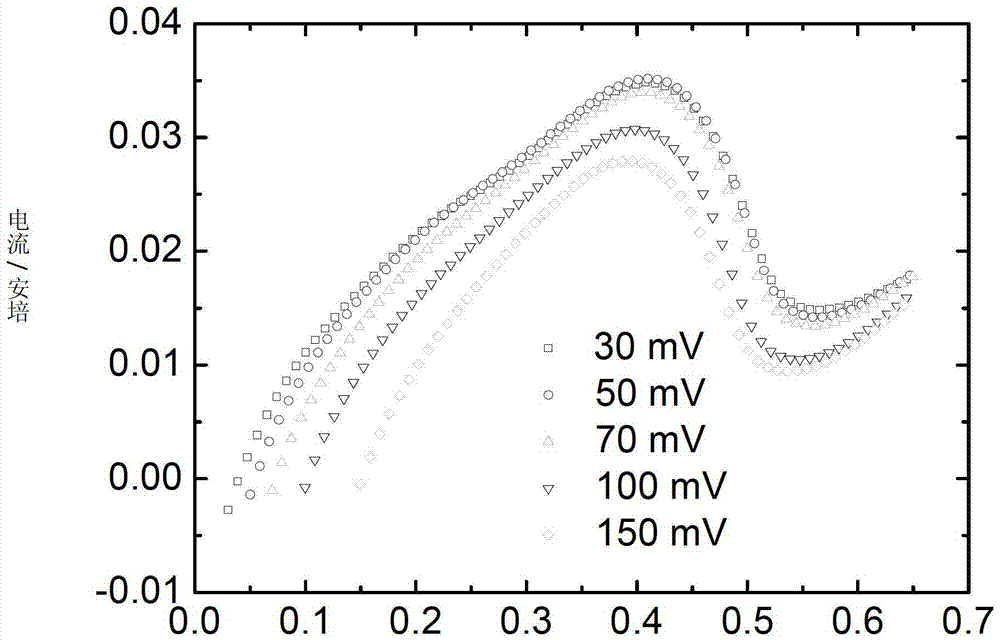

Preparation and application of MXene quantum dot activated one-dimensional TiO2 nano composite photoanode

ActiveCN113436896ALoad controlImprove stabilityLight-sensitive devicesPhotovoltaic energy generationConjugated PolyelectrolytesHeterojunction

The invention belongs to the technical field of photoelectrode material preparation and photoelectrocatalysis, and particularly relates to preparation and application of an MXene quantum dot activated one-dimensional TiO2 nano composite photoanode. MXene quantum dots, non-conjugated polyelectrolyte PDDA and a one-dimensional TiO2 nanorod array are combined together in an electrostatic layer-by-layer self-assembly mode to form a multi-layer heterojunction photoanode, and is applied to photoelectrocatalytic water decomposition. According to the preparation method, the MXene quantum dots are used for activating the one-dimensional TiO2 nanostructure coated with the polyelectrolyte for the first time, the prepared photoanode has efficient photoelectrocatalysis capacity, and the loading capacity of the MXene quantum dots can be achieved by regulating and controlling the number of self-assembly layers. The whole preparation process is simple, the design principle is reliable, and sustainable development of the environment and energy is facilitated.

Owner:FUZHOU UNIV

A kind of steel fiber feeding and dispersing device and dispersing method

ActiveCN108858789BNo cloggingEvenly dispersedPretreatment controlSold ingredients supply apparatusConveyor beltMaterials science

The invention discloses a steel fiber feeding and dispersing device and a dispersing method. A conveyor belt is arranged in a steel fiber conveying and dispersing arm, and the bottom surface of one end of the steel fiber conveying and dispersing arm is arranged at the upper end of a dispersing support column; a dispersing hopper is arranged on the end head of the steel fiber conveying and dispersing arm, and a discharge port is formed in the bottom surface of the other end of the steel fiber conveying and dispersing arm; a blanking cage is arranged in the dispersing hopper, and the blanking cage is driven by a blanking cage motor arranged outside the dispersing hopper to rotate; scrapping rake teeth are arranged on cage ribs of the blanking cage in disorder, the blanking cage continuouslyrotates, the steel fibers stacked at the upper part of the blanking cage are continuously racked off by the scraping rake teeth, and the dropped steel fibers are dispersed on the conveyor belt throughthe blanking cage; a rotary rocker arm support rack is arranged the dispersing support column corresponding to the lower part of the steel fiber conveying and dispersing arm, and the bottom surface of one end of a steel fiber rotary rocker arm is arranged at the outer end part of the rotary rocker arm support rack; a steel fiber receiving hopper is arranged on the end head of the steel fiber rotary rocker arm.

Owner:成都东蓝星新材料有限公司

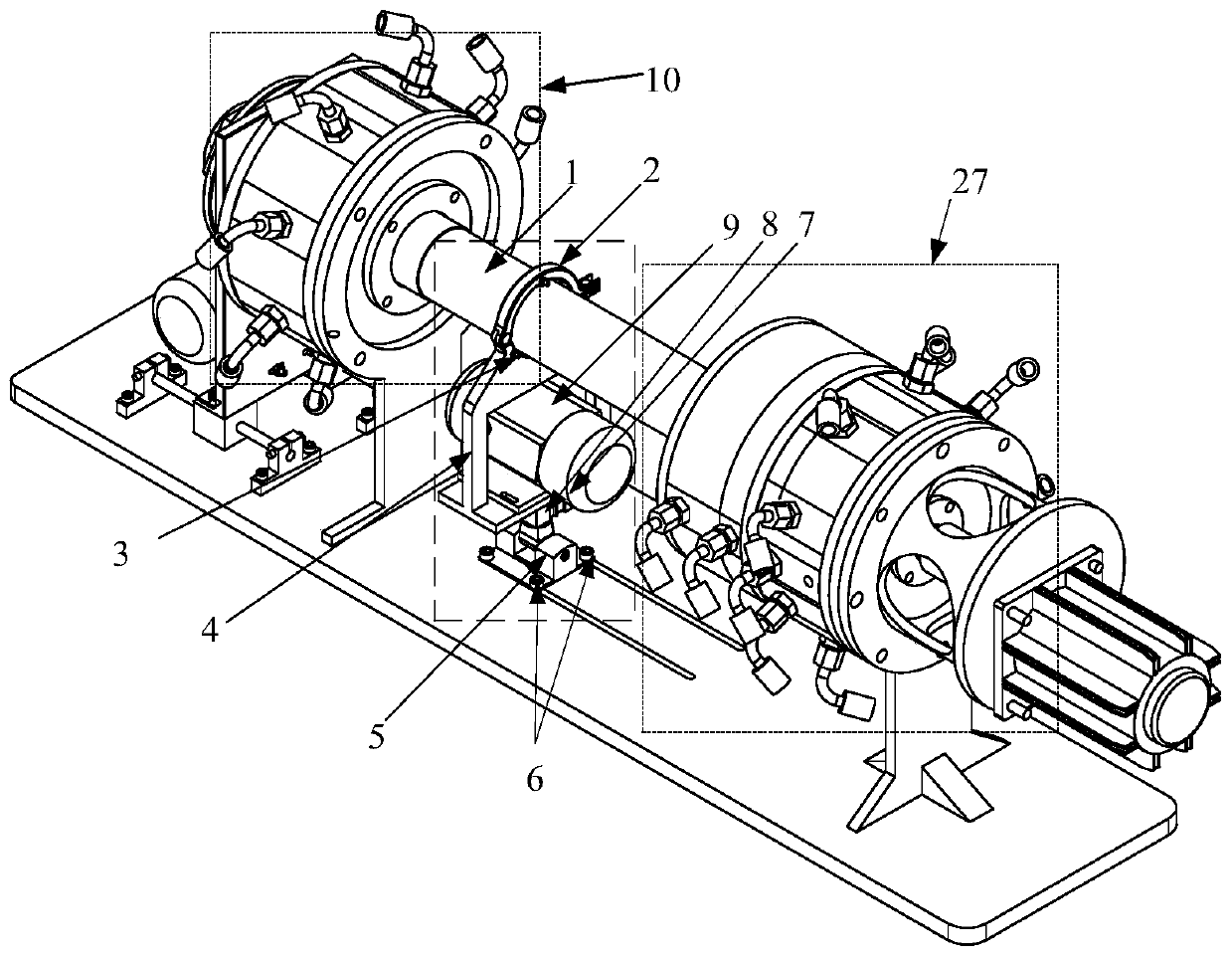

A radial loading device for an experimental platform for bearing performance testing

ActiveCN108760303BLoad controlFacilitate experimental researchMachine bearings testingExperimental researchConstant force

The invention provides a radial loading device for a bearing performance test experimental platform, which mainly arranges a radial loading device on a platform corresponding to a stepped shaft. The radial loading device is mainly provided with a vibration motor and a vibration isolating assembly on the upper and lower sides of a base frame. The base frame includes a base frame top cover and a base frame body. The base frame body and the base frame top cover are opposite to each other and form a complete circle for holding the stepped shaft, the opening of a base frame vertical plate is internally provided with the vibration motor, a pneumatic cylinder is connected below a base frame horizontal plate connected to the vibration motor, the pneumatic cylinder is connected to a base through abottom connection member, and the lower ends of the base bottom plate are arranged in two sliding slots in parallel of a test platform. The invention can convert the exciting force of the vibration motor and the constant force of the pneumatic cylinder into the load force on the stepped shaft of the tested bearing, and can regulate the load force on the stepped shaft by adjusting the vibration frequency, the amplitude and the overall position of the vibration motor, thereby greatly facilitating the experimental research and exploration of bearing support characteristics.

Owner:YANSHAN UNIV

Preparation and application of a one-dimensional titanium dioxide nanocomposite photoanode activated by mxene quantum dots

ActiveCN113436896BLoad controlImprove stabilityLight-sensitive devicesPhotovoltaic energy generationConjugated PolyelectrolytesHeterojunction

The invention belongs to the technical field of photoelectrode material preparation and photoelectric catalysis, in particular to a one-dimensional TiO2 activated by MXene quantum dots 2 Preparation and application of nanocomposite photoanode, through electrostatic layer-by-layer self-assembly, makes MXene quantum dots, non-conjugated polyelectrolyte PDDA and one-dimensional TiO 2 The nanorod arrays are combined to form a multilayer heterojunction photoanode and applied to photocatalytic water splitting. The present invention uses MXene quantum dots to activate polyelectrolyte-coated one-dimensional TiO for the first time 2 Nanostructure, the prepared photoanode has efficient photoelectric catalytic ability, and the loading of MXene quantum dots can be realized by adjusting the number of self-assembled layers. The overall preparation process of the invention is simple, the design principle is reliable, and the sustainable development of environment and energy is favorable.

Owner:FUZHOU UNIV

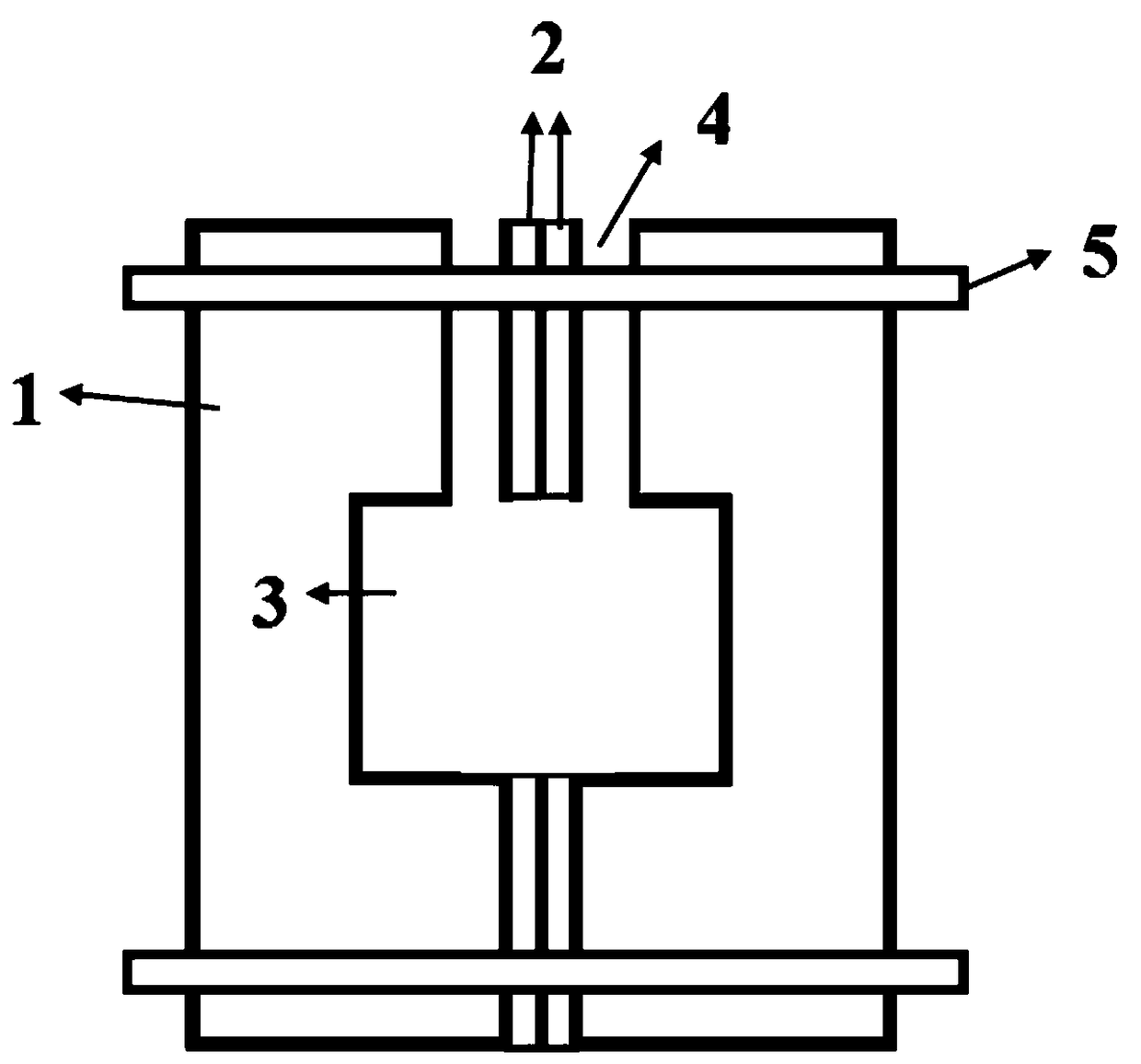

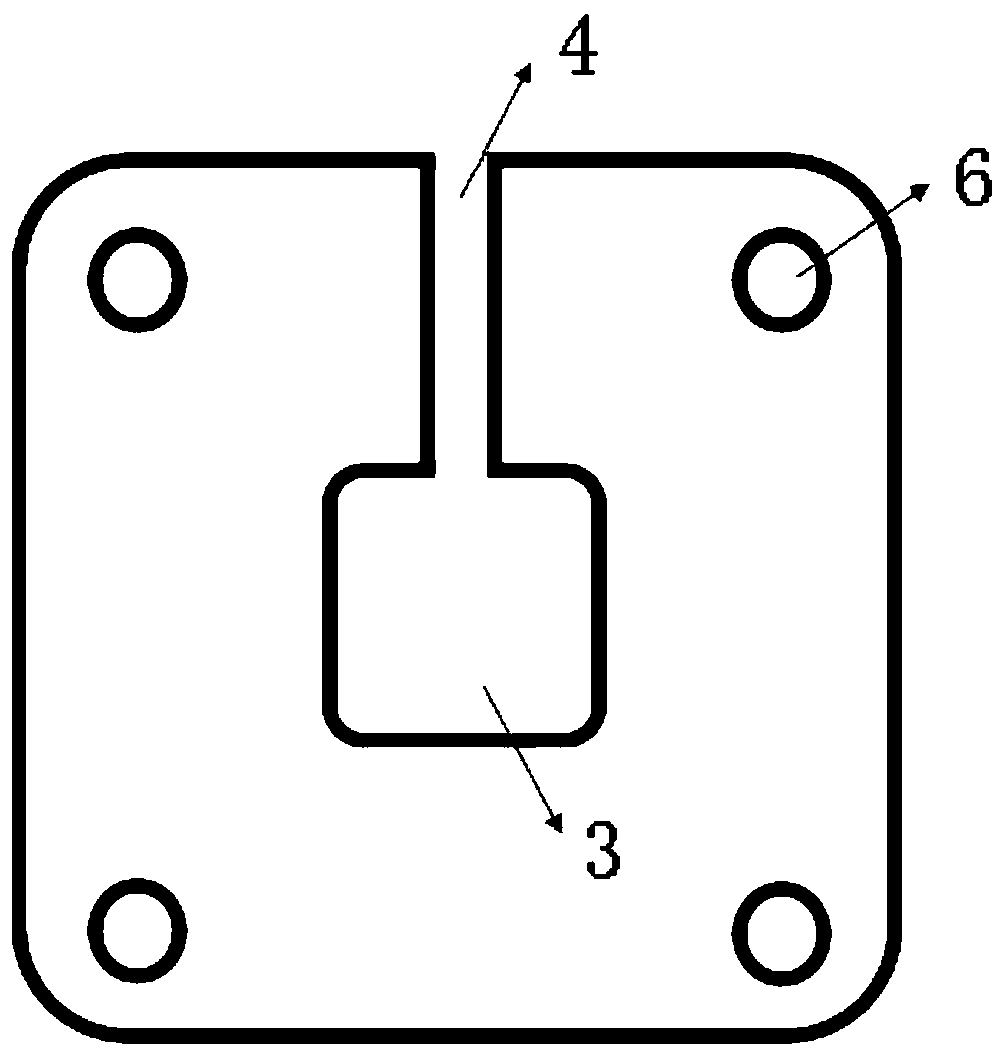

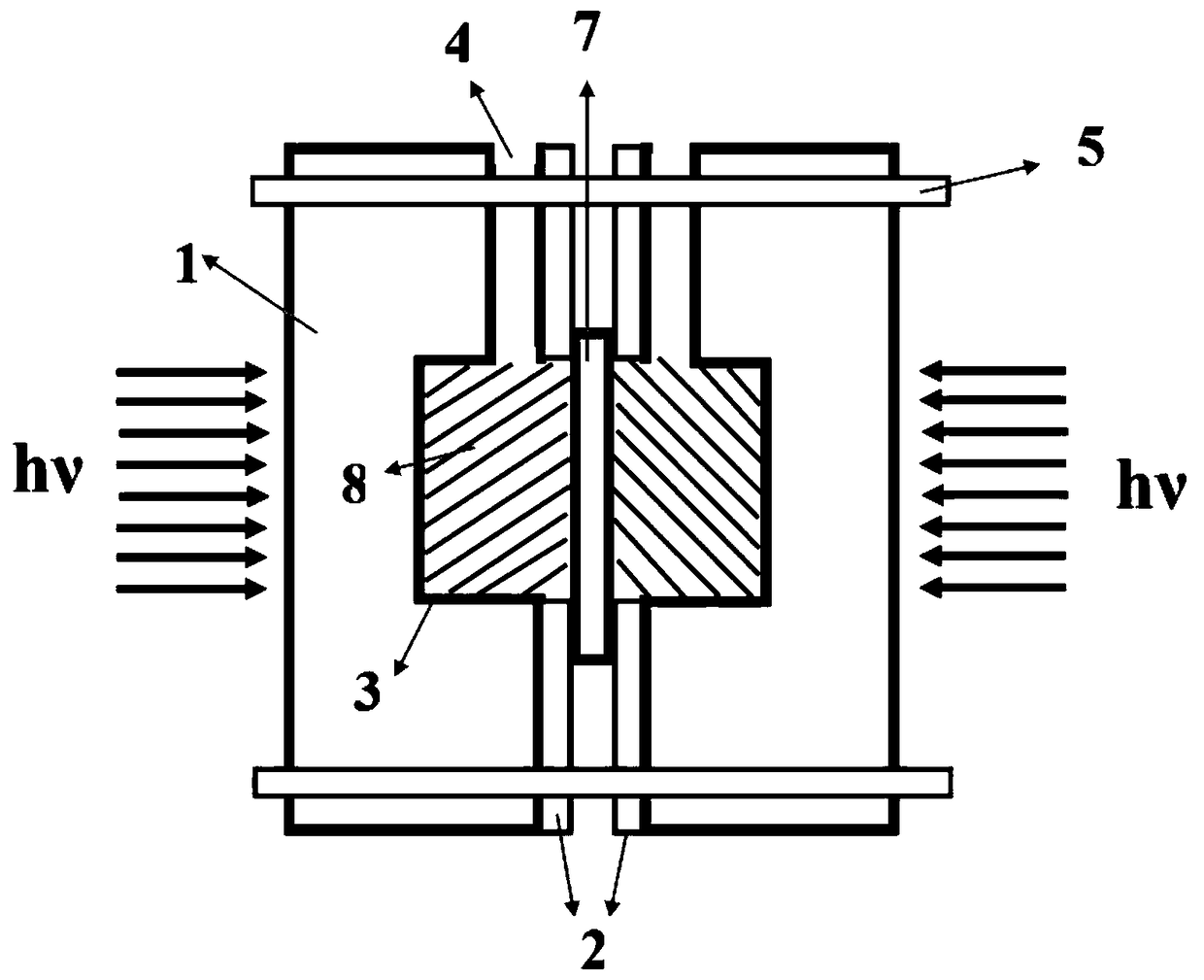

A method, device and application of light-driven rapid preparation of membrane electrodes

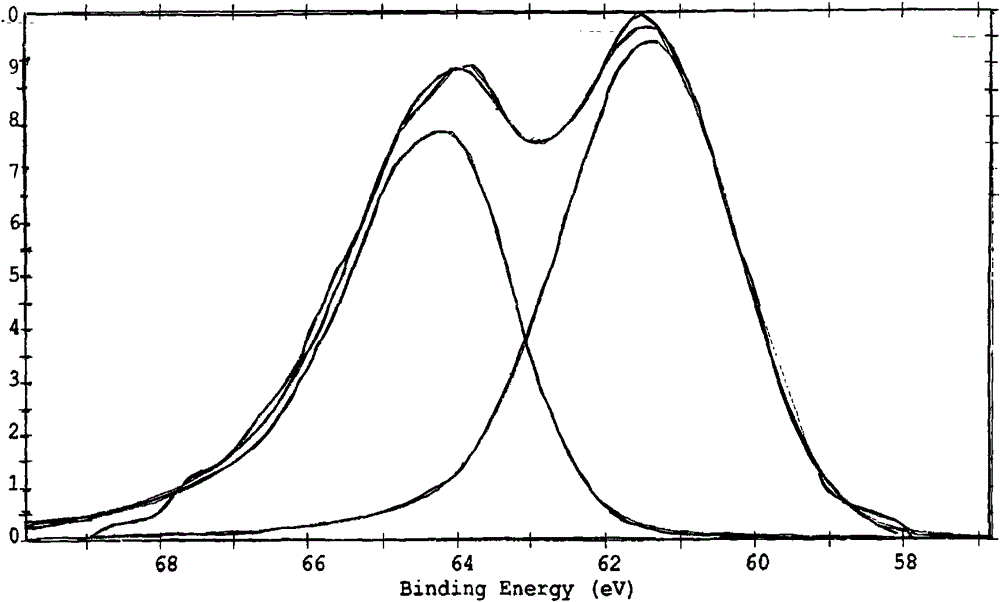

ActiveCN104900893BFast preparationEasy to mass produceFinal product manufactureCell electrodesPolymer electrolytesLight driven

The invention discloses a method, device and application for rapidly preparing a membrane electrode driven by light. A polymer electrolyte membrane loaded with a metal macrocyclic compound is placed in a reaction device, and a platinum metal precursor and a reducing agent are added to the reaction pool. The mixed solution of platinum nucleates and grows rapidly on the polymer electrolyte membrane under light conditions to obtain a membrane electrode. This method has a simple process, can quickly prepare membrane electrodes, has good repeatability, and is easy to mass-produce membrane electrodes.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Gas diffusion electrode carried with double-shell core-shell catalyst and preparation and application thereof

ActiveCN102881916BHigh utilization of PtIncrease profitCell electrodesCarrying capacityAlloy catalyst

Owner:中科军联(张家港)新能源科技有限公司

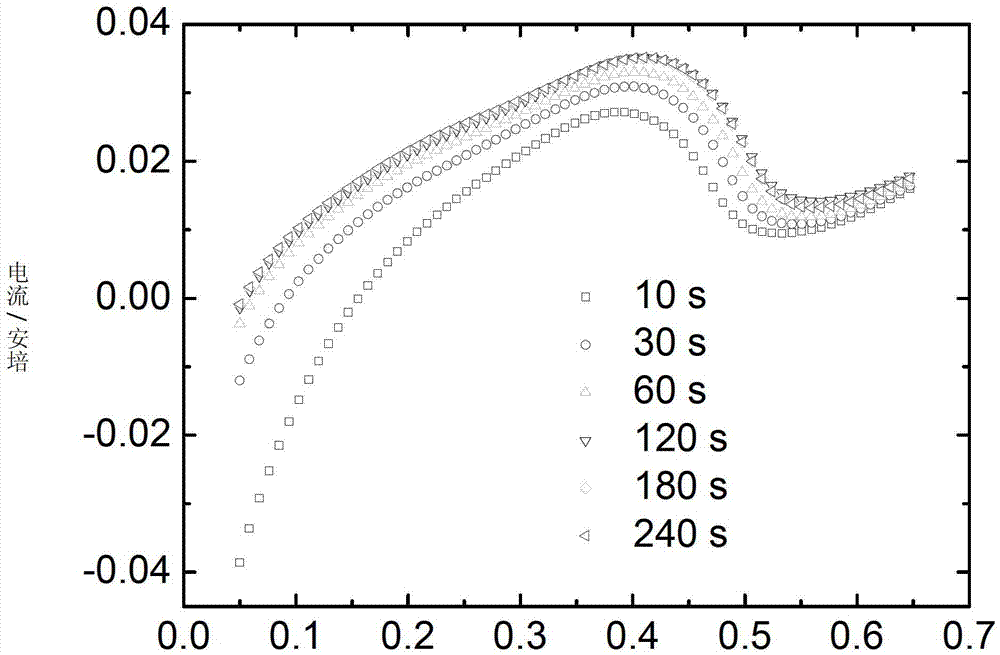

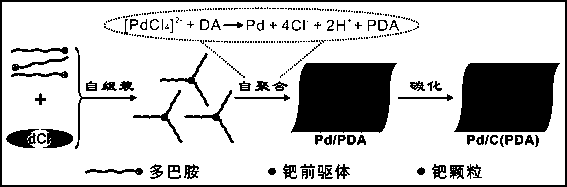

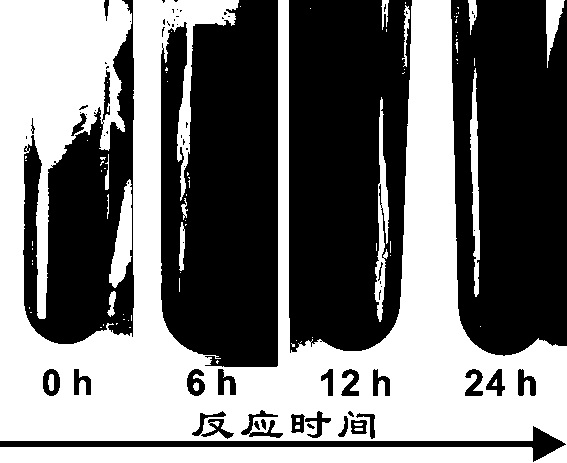

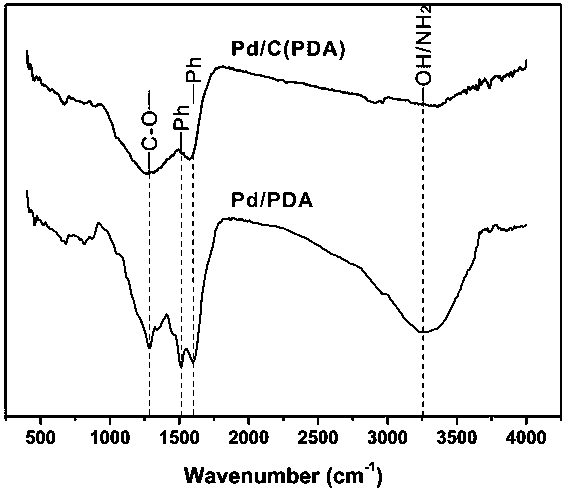

Method and application of preparing supported palladium carbon catalyst by self-polymerization of dopamine

The invention belongs to the technical field of preparation, relates to preparation of supported palladium / carbon catalyst and particularly relates to a method for preparing supported palladium / carbon catalyst through self-polymerization of dopamine, and application. The method for preparing the supported palladium / carbon catalyst through self-polymerization of dopamine comprises the steps of enabling metal precursor chloropalladite and DA to automatically carry out oxidation-reduction reaction in an alkalescence (pH 8.5) environment, thereby obtaining Pd / PDA compound; and carbonizing Pd / PDA compound in inert atmosphere (N2), thereby obtaining the supported Pd / C(PDA) catalyst. The preparation method disclosed by the invention is very simple, is few in step and convenient in operation. Through control of input of the metal precursor, the capacity of precious metal can be controlled. The supported palladium / carbon catalyst prepared by the method has excellent activity for electrocatalytic oxidation of methanol in the alkaline environment and has good application prospect in the field of a low-temperature methanol fuel cell.

Owner:江阴智产汇知识产权运营有限公司

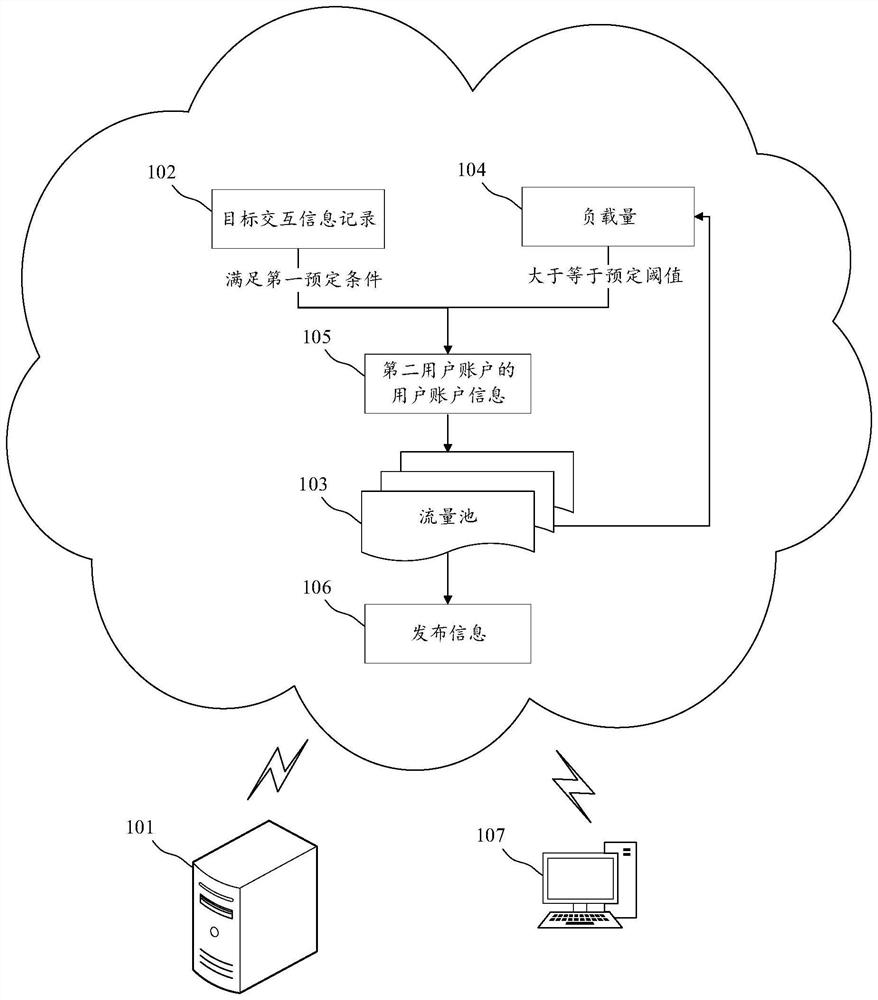

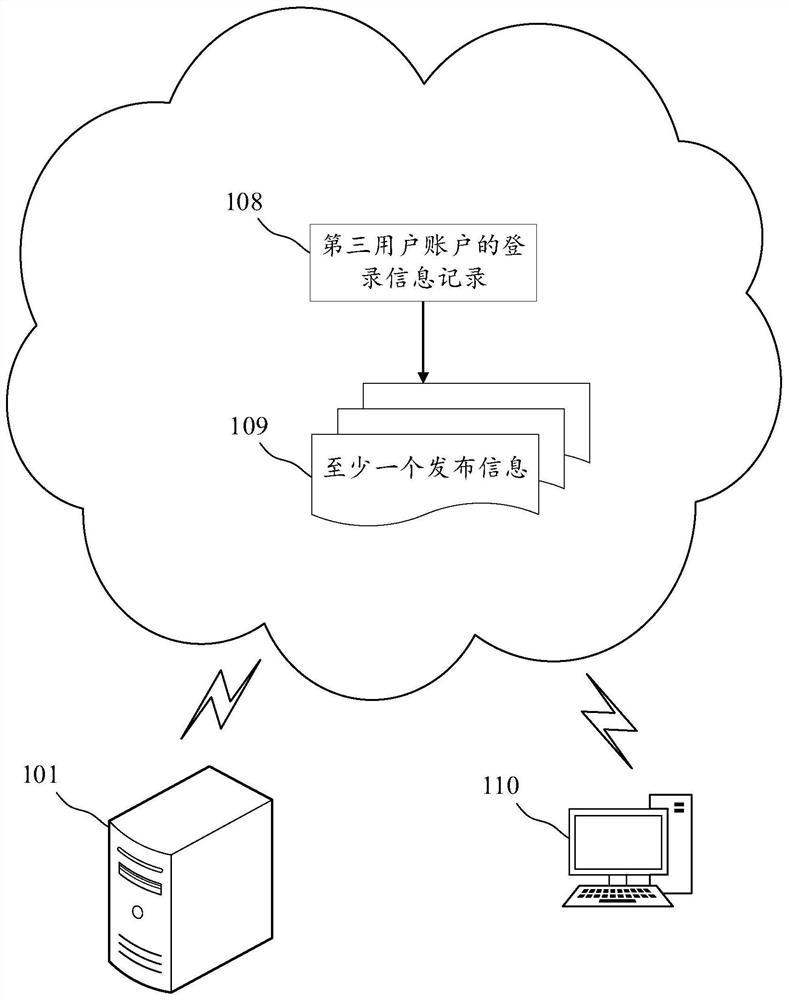

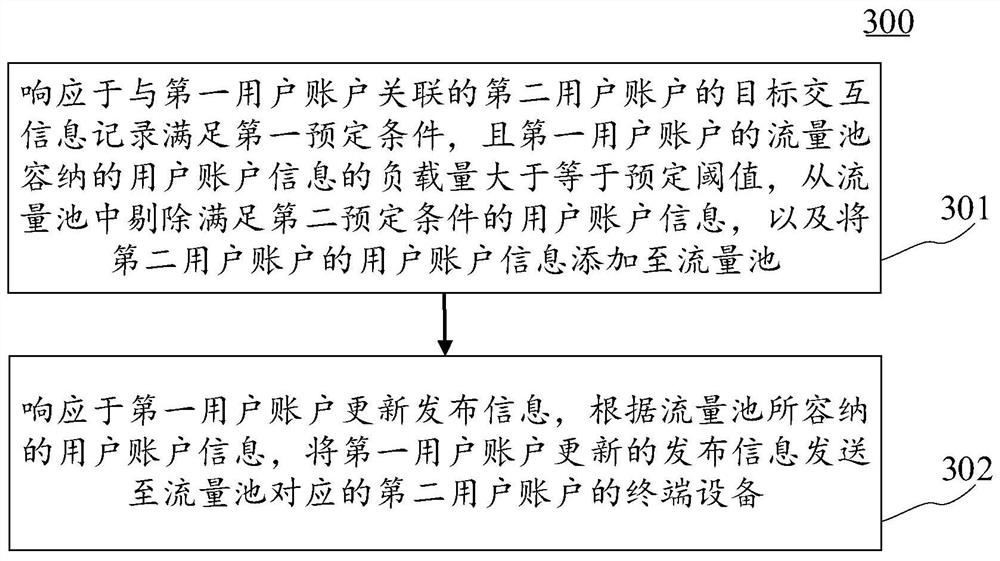

Information sending method and device, electronic equipment and computer readable medium

ActiveCN112637048AReduce utilizationLoad controlData switching networksData miningOperations research

The embodiment of the invention discloses an information sending method and device, electronic equipment and a computer readable medium. One specific embodiment of the method comprises the steps of responding to a situation that a target interaction information record of a second user account associated with a first user account satisfies a first predetermined condition and the load capacity of user account information accommodated in a flow pool of the first user account is greater than or equal to a predetermined threshold, removing the user account information meeting a second preset condition from the flow pool, and adding the user account information of the second user account to the flow pool; and in response to the first user account updating release information, sending the release information updated by the first user account to terminal equipment of a second user account corresponding to the flow pool according to the user account information contained in the flow pool. According to the embodiment, the release information updated by the first user account is sent to the terminal equipment of the user account with more requirements for browsing the release information, so that the utilization rate of the sent release information can be improved, and network transmission resources are saved.

Owner:BEIJING CHENGSHI WANGLIN INFORMATION TECH CO LTD

A kind of unmanned aerial vehicle flight control method and device

InactiveCN106681314BImprove securityEffective flight controlControl safety arrangementsPosition/course control in three dimensionsUncrewed vehicleFlight velocity

Theinvention provides a flight control method and device of an unmanned aerial vehicle, and relates to the field of electronic technologies. The flight control method comprises the steps of obtaining a first flight state of the unmanned aerial vehicle, wherein the first flight state includes a first velocity; obtaining loading information about the unmanned aerial vehicle; determining a first buffer distance of the unmanned aerial vehicle according to the first flight state of the unmanned aerial vehicle; determining a second buffer distance of the unmanned aerial vehicle according to the loading information and the first buffer distance. The problem in the prior art is solved that when the loading unmanned aerial vehicle executes instructions and as the unmanned aerial vehicle has no mechanism to adjust the instructions, operation performed is no longer applicable in the buffer downtime, and thus such a risk as collision between the unmanned aerial vehicle and obstacles happens. The flight control method and device have the advantages of effectively controlling the unmanned aerial vehicle flight and downtime, and improving the safety of the loading unmanned aerial vehicle and operators.

Owner:EWATT TECH CO LTD

Graphene/calcium phosphate ceramic composite scaffold with antibacterial function and preparation method

ActiveCN112745142BImprove biological performanceLight and heat synergistic antibacterial performance is goodCoatingsCeramicwareCalcium biphosphateCeramic composite

The invention belongs to the technical field of biomedical materials, and discloses a graphene / calcium phosphate ceramic composite stent with antibacterial function and a preparation method. In the preparation method of the present invention, the porous calcium phosphate ceramic is placed in a graphene-based material solution of a certain concentration, the graphene is adsorbed on the surface and pores of the porous calcium phosphate ceramic by vacuum perfusion, and the graphene / calcium phosphate ceramic is obtained after drying treatment. Composite bracket. The graphene / calcium phosphate ceramic composite scaffold prepared by the invention not only has good osteoinductive properties, but also has good antibacterial activity, and is expected to have broad application prospects in the regeneration and repair of clinical infectious bone defects.

Owner:SICHUAN UNIV

Preparation method of polystyrene microspheres with casein supported on surface

InactiveCN104084097ALoad controlThe load is easy to controlMicroballoon preparationMicrocapsule preparationEmulsionMicrosphere

The invention discloses a preparation method of polystyrene microspheres with casein supported on the surface. The preparation method comprises the following steps: dissolving a casein aqueous solution under an alkalescent condition, preparing the aqueous solution and regulating the pH value of the aqueous solution; adding a little of comonomer divinyl benzene into styrene monomer, adding a proper amount of polymerization initiator and dissolving; adding a proper quantity of two components prepared in advance into a polymerization device, mixing at certain mixing speed and emulsifying uniformly; heating the emulsion till the emulsion reaches reaction temperature, performing polymerization reaction, filtering, washing and drying to obtain the microspheres. Casein macromolecules are inlaid in the surface of the microspheres by the technical method, and the supporting capacity of the surface of the microspheres can be controllably adjusted in a process ratio and through the change of polymerization conditions.

Owner:IANGSU COLLEGE OF ENG & TECH

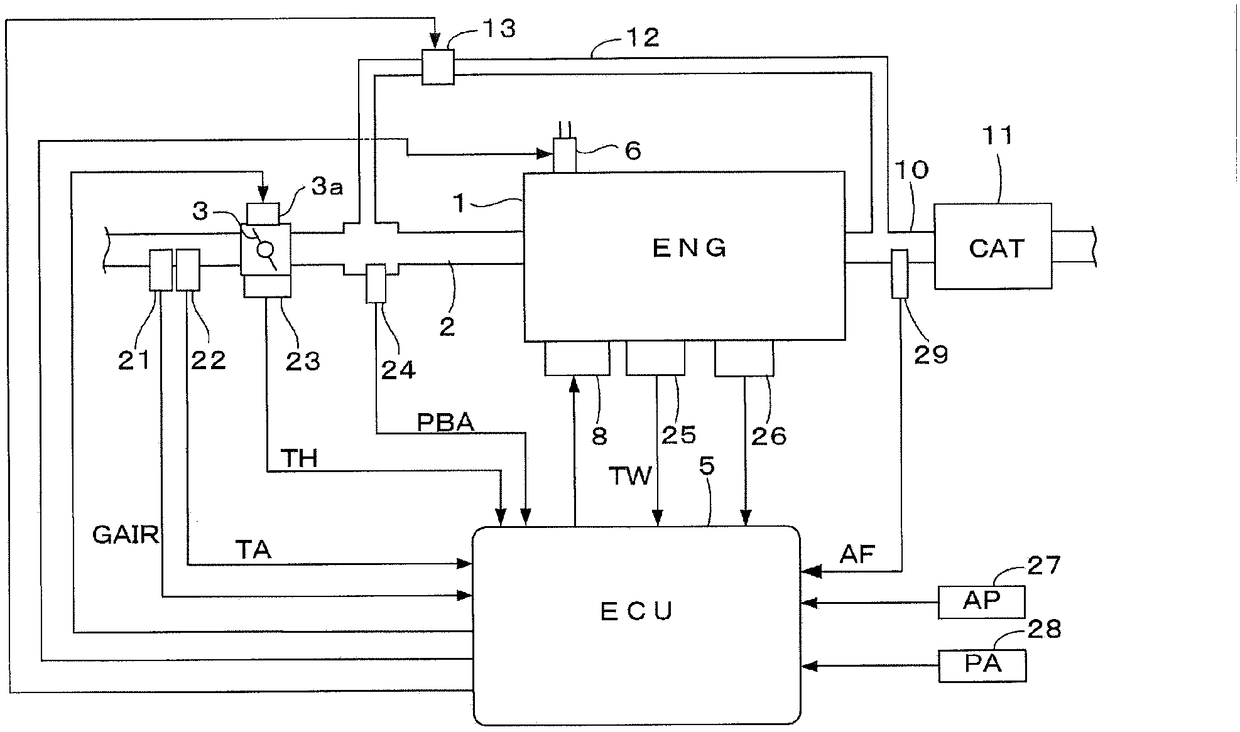

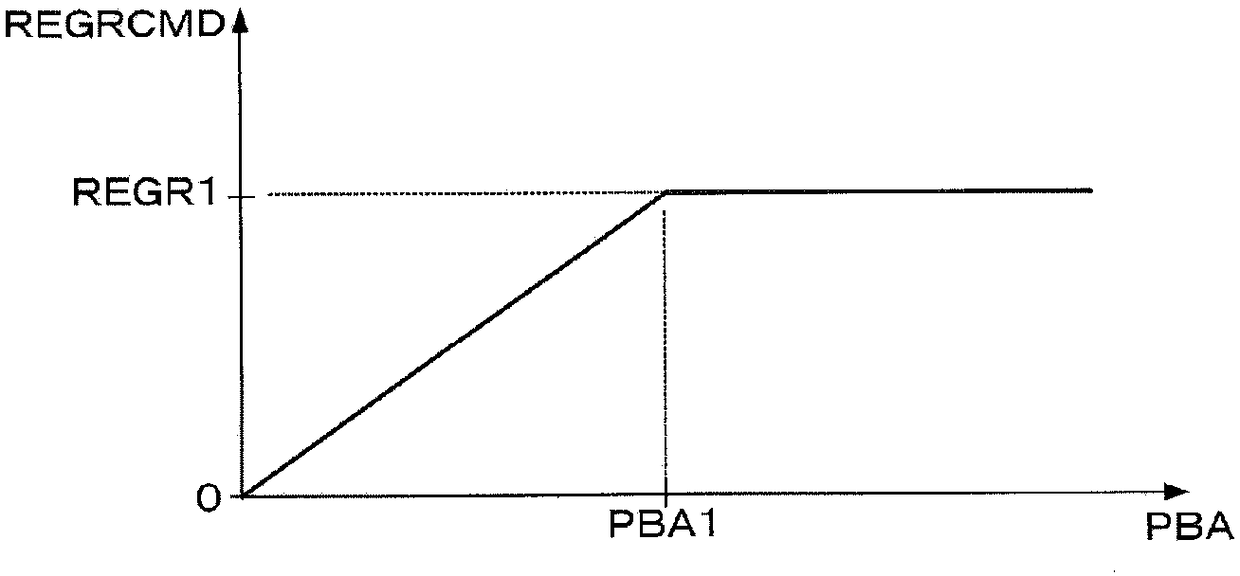

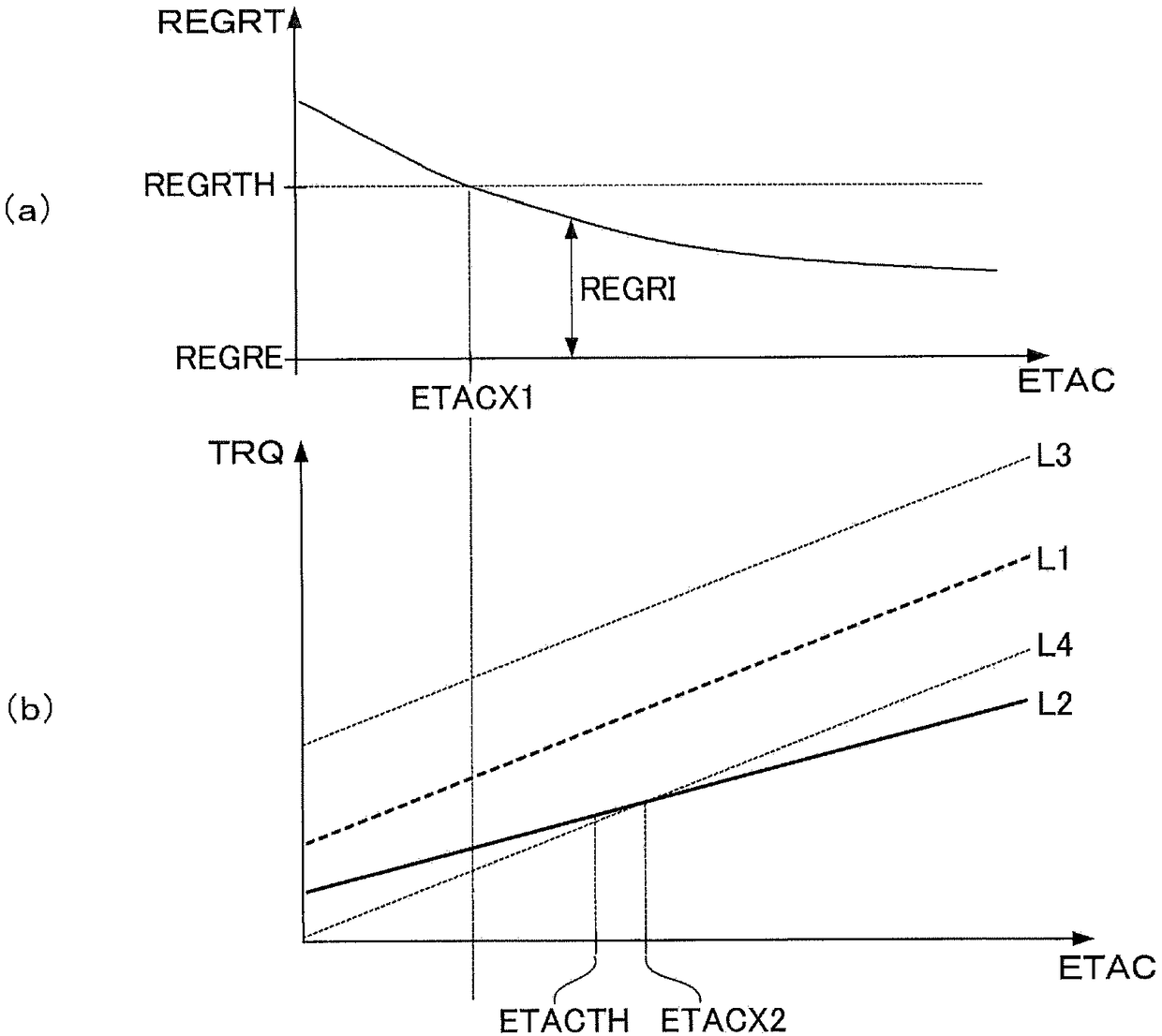

Control device for internal combustion engine

InactiveCN108317017ALoad controlElectrical controlInternal combustion piston enginesCombustion instabilityEngineering

The present invention provides a control device for an internal combustion engine, being able to suppress engine misfire by appropriately controlling the ignition period when the engine deceleration is performed in a state that the exhaust gas recirculation rate is high. When the exhaust gas recirculation rate exceeds the combustion instability threshold and the estimated filling efficiency indicating the engine load is less than the specific retard control threshold, the ignition period is configured to be the specific retard limit control at a specific ignition period of a retard corner side, compared with the optimal ignition period by taking a compression stroke end period as the retard limit. In the compression stroke, the temperature of the in-cylinder gas rises due to compression. Therefore, by taking compression stroke end period as the retard limit, the ignition is performed at a specific ignition period at the retard corner side, compared with the optimal ignition period, andstable ignition and suppression of engine misfire can be performed, compared with the situation that ignition is performed at the optimal ignition period.

Owner:HONDA MOTOR CO LTD

A preparation method of fuel particles and core-shell fuel particles obtained therefrom

ActiveCN109545414BImprove securityImprove economyNuclear energy generationReactors manufactureCarbide siliconNeutron poison

The invention relates to a method for preparing fuel particles. The method comprises the steps: supplying a spherical core, performing formation of a porous silicon carbide layer or a zirconium carbide layer on the core through chemical vapor deposition so as to obtain porous silicon carbide layer / zirconium carbide layer-coated particles, soaking the porous silicon carbide layer / zirconium carbidelayer-coated particles in an active liquid for vacuum impregnation so as to obtain compound-filled porous silicon carbide layer / zirconium carbide layer-coated particles, and decomposing compounds which are filled in the compound-filled porous silicon carbide layer / zirconium carbide layer-coated particles so as to form combustible neutron-poison oxides or thorium oxide and finally obtain the fuel particles. The invention also provides core-shell fuel particles prepared by using the method. The fuel particle safety which is stack safety is improved through coating of the silicon carbide layer orthe zirconium carbide layer outside the core, and meanwhile the stack economy can be improved through the combustible neutron-poison oxides or thorium oxide filled in the silicon carbide layer or zirconium carbide layer.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

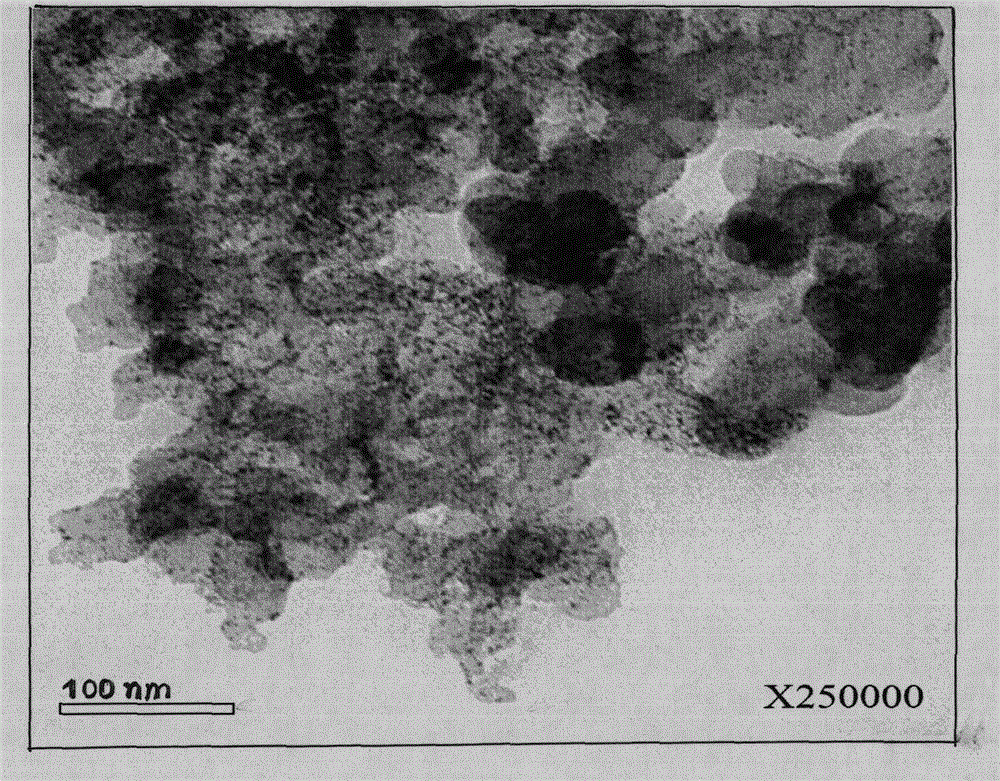

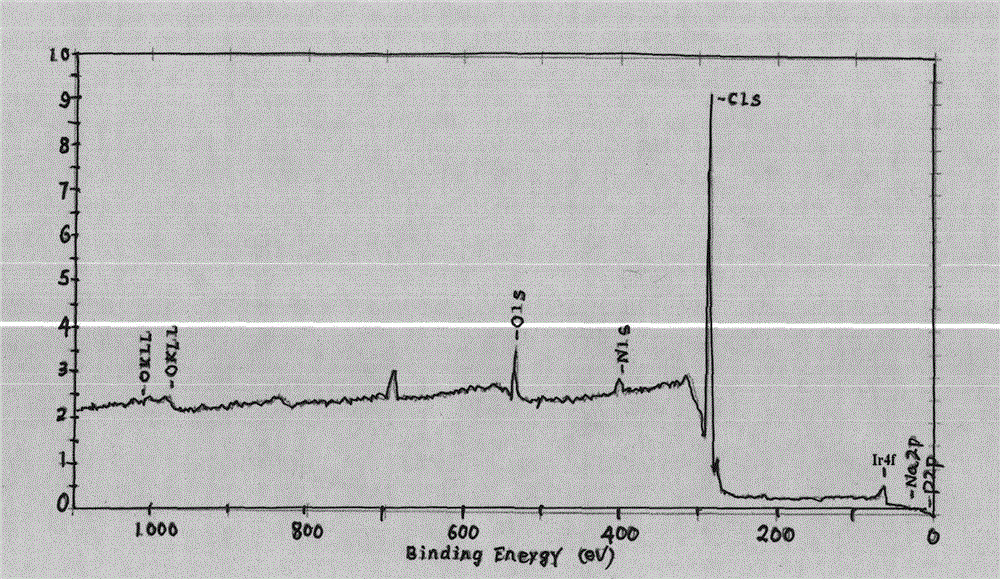

Preparation method of Ir and Ir-Pt/C alloy nano-catalyst with high dispersion and high load capacity

InactiveCN101966458BHigh load rateEnhanced interactionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystMetallurgy

Owner:KUNMING UNIV OF SCI & TECH

A kind of catalyst for synthesis of clay-based c22-cycloaliphatic triester and preparation method thereof

InactiveCN103736507BEasy to separateReduce pollutionPhysical/chemical process catalystsOrganic compound preparationPlasticizerSolvent

The invention belongs to the field of preparation of biological plasticizers and relates to a clay-based solid catalyst for green synthesis of a novel biological plasticizer C22-cyclolipotri-acid ester and a preparation method thereof. The preparation method comprises the following steps: adopting silicate clay and zinc oxide as materials, adopting an equivalent-volume impregnation method to load a proper amount of zinc oxide into inner holes of the silicate clay; then drying to remove a solvent, and by the action of roasting and activation, and obtaining the catalyst for synthesis of the clay-based C22-cyclolipotri-acid ester. The prepared solid catalyst is easily separated from products, so that the corrosion to equipment and the pollution to the environment are reduced; in the loading type catalyst, ZnCl2 and the surface of clay generate chemical bonding action to form a new amorphous substance, and the activity is larger than the sum of the activity of the ZnCl2 and the activity of the clay.

Owner:CHANGZHOU UNIV

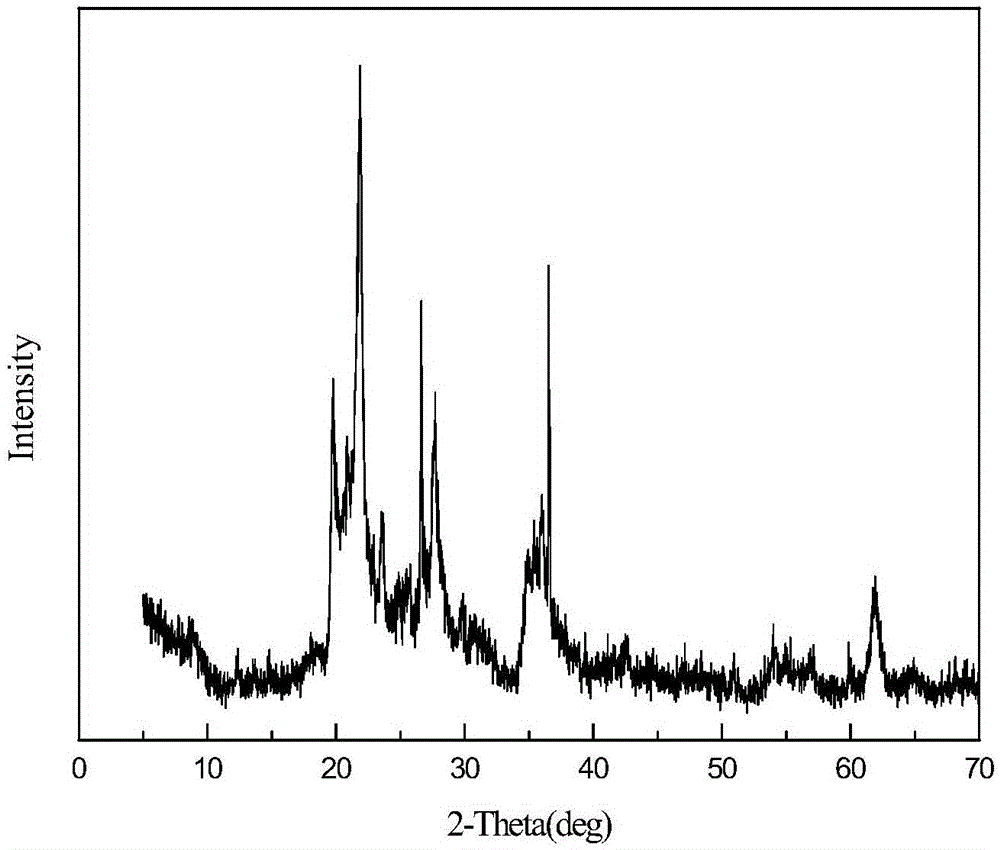

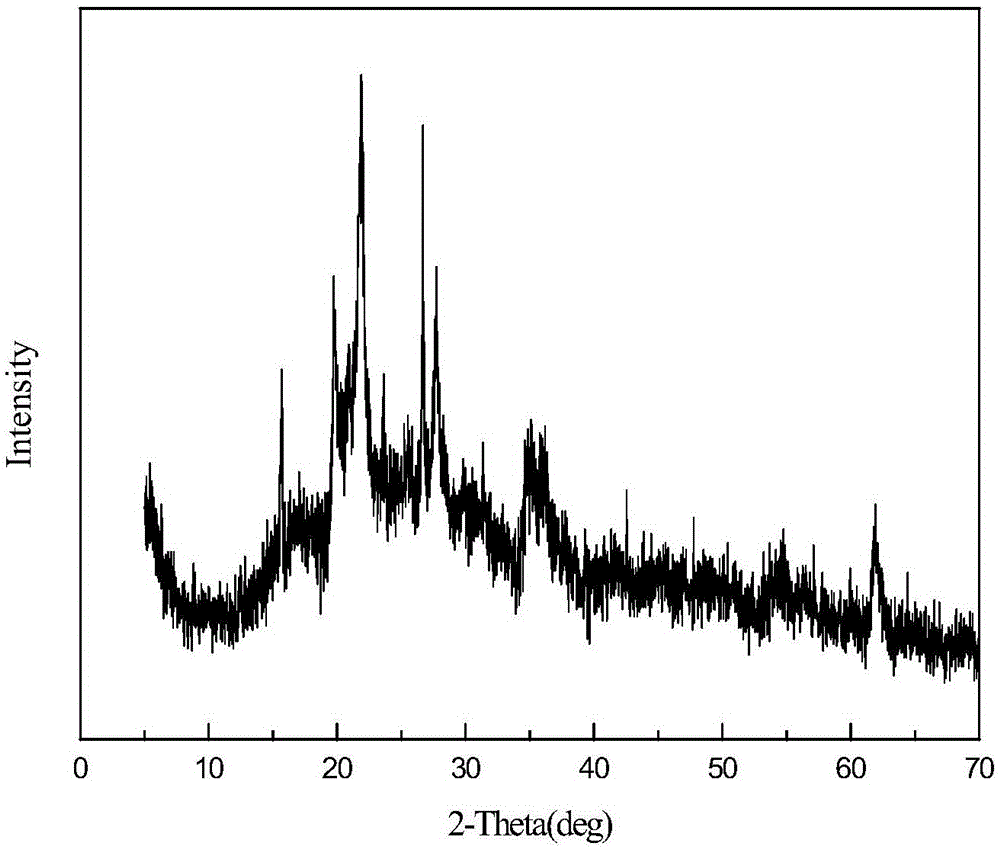

Manganese dioxide modified biochar composite material and its preparation method and application

ActiveCN107983300BImprove adsorption capacityReduce manufacturing costOther chemical processesWater contaminantsSorbentManganese

The invention discloses a manganese dioxide modified biochar composite material as well as a preparation method and an application thereof. The composite material is prepared from manganese dioxide and biochar by loading generated manganese dioxide on biochar through the neutralization reaction of permanganate and manganese in divalent manganese salt. The manganese dioxide modified composite material has the advantages of high adsorption capacity for heavy metal lead or cadmium, obvious adsorption effect, low preparation cost and the like, and is an ideal heavy metal wastewater adsorbent; thepreparation method of the composite material has the advantages of simple process, cheap raw materials, sufficiently used raw materials, low production cost and the like. The manganese dioxide modified composite material can be used for treating heavy metal wastewater, and has the advantages of high adsorption capacity for heavy metals, high adsorption efficiency, low toxicity to organisms in theenvironment and the like, and can be produced and applied on a large scale.

Owner:HUNAN UNIV

A kind of hydrogel that can be loaded with high hydrophobicity drug and its preparation method and application

ActiveCN113416292BGood biocompatibilityGood physiological acceptabilityOrganic active ingredientsAerosol deliveryBound drugPolymer science

The invention provides a hydrogel capable of loading high hydrophobicity drugs, a preparation method and application thereof, and belongs to the technical field of polymer material preparation. The invention firstly prepares a cyclodextrin-terminated side chain containing double bond polyurethane (DPU), and utilizes the click chemical cross-linking of the polysulfhydryl compound and the double bond to form the polyurethane hydrogel. Since the inner cavity of the cyclodextrin is hydrophobic and the outer edge is hydrophilic, it can provide a hydrophobic binding site, so the cyclodextrin molecular cavity in the polyurethane hydrogel can be non-covalently combined with highly hydrophobic drugs, thereby The loading of highly hydrophobic drugs is realized, and the gel is very stable in vitro. Under the action of enzymes in vivo, the cyclodextrin polysaccharide is gradually degraded, so that the bound drugs are released, thereby successfully preparing a high-loading gel. The hydrogels of hydrophobic drugs therefore have good practical application value.

Owner:CHANGSHA JINGYI PHARM TECH CO LTD

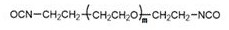

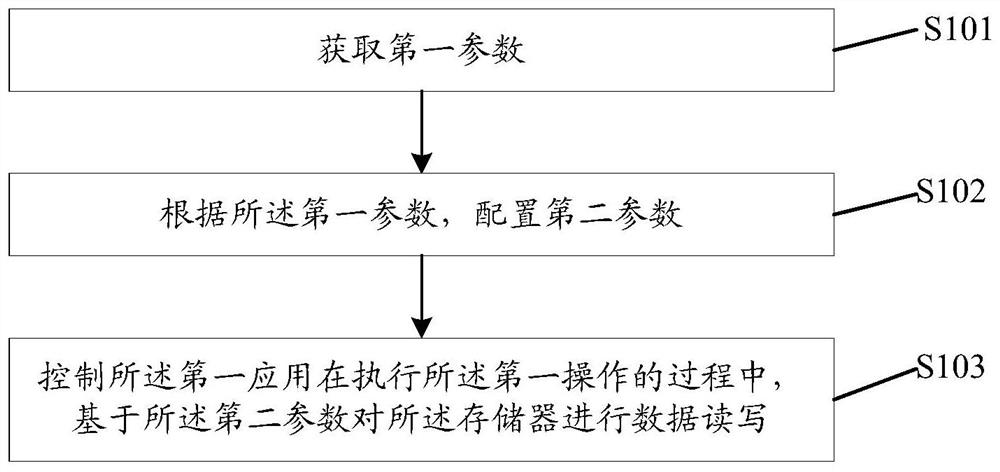

Data migration method and device, electronic equipment and storage medium

PendingCN114327253AAvoid load increaseAvoid high loadsInput/output to record carriersComputer hardwareEngineering

The invention discloses a data migration method and device, a terminal and a storage medium. The method comprises the following steps: acquiring a first parameter; the first parameter represents the load capacity for performing read-write operation on a memory in the first electronic equipment; configuring a second parameter according to the first parameter; the second parameter represents a read-write data volume within unit time configured by the first application; the first application is used for executing data migration among different electronic devices; controlling the first application to perform data reading and writing on the memory based on the second parameter in the process of executing the first operation; the first operation is used for migrating each second application in at least one second application on the first electronic equipment to second electronic equipment.

Owner:HANGZHOU DOUKU SOFTWARE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com