A kind of catalyst for synthesis of clay-based c22-cycloaliphatic triester and preparation method thereof

A solid catalyst and clay technology, which is applied in the field of clay-based solid catalyst and its preparation, can solve problems such as unfavorable catalyst and product separation, equipment corrosion, environmental pollution, etc., to achieve large-scale industrial production, low production cost, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

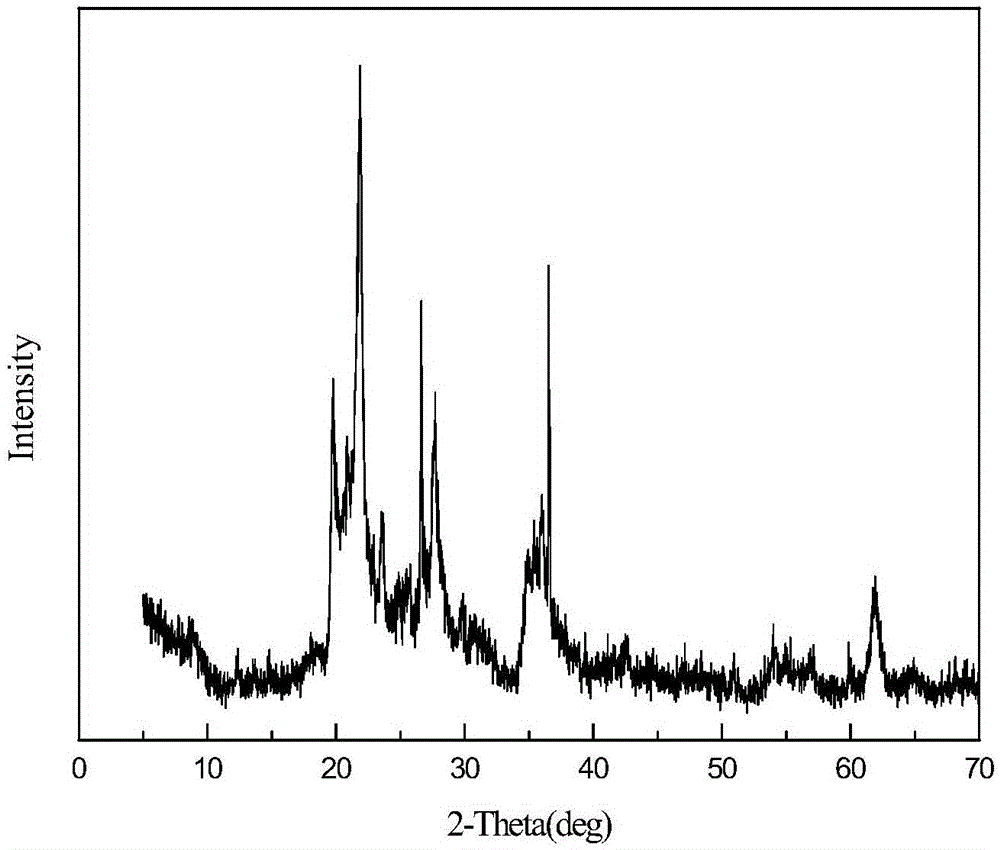

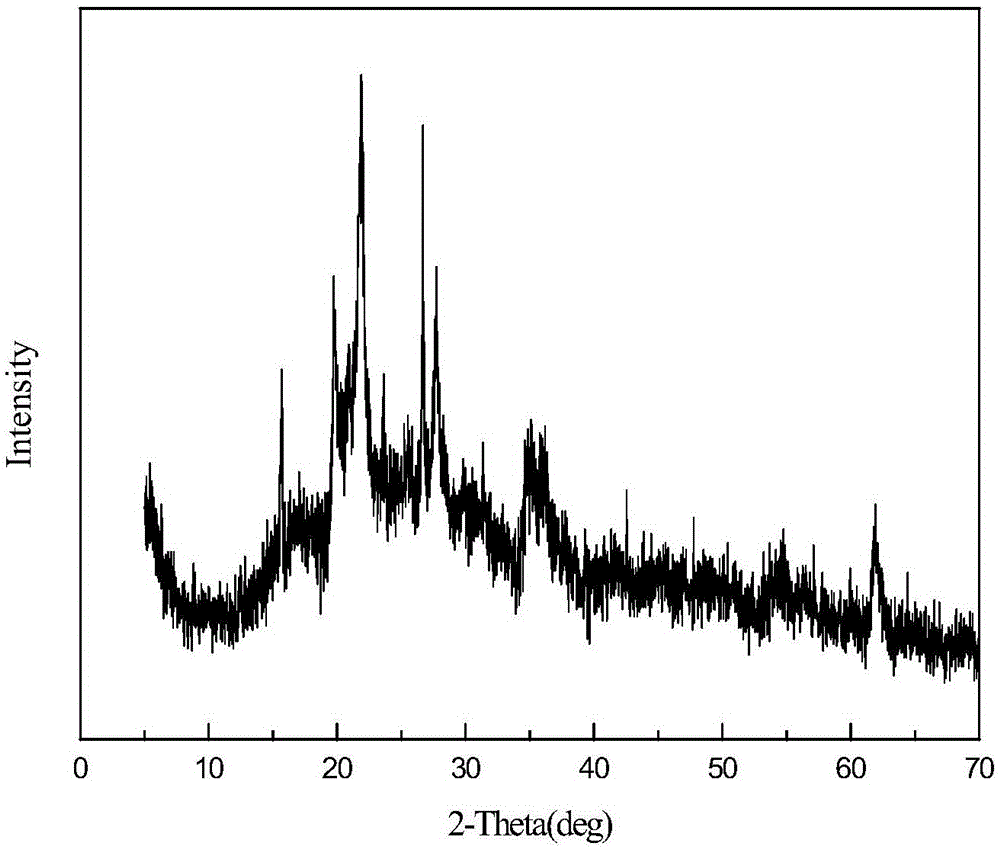

Embodiment 1

[0024] 1. Dry the attapulgite, and determine the specific pore volume of the attapulgite to be 2.64mL / g by the water adsorption weighing method; weigh 10kg of the attapulgite after drying to prepare ZnCl 2 26.4L methanol solution with a concentration of 0.1mol / L; while stirring the attapulgite, add the ZnCl 2 Spray the methanol solution on the attapulgite evenly;

[0025] 2. To be impregnated with ZnCl as described in step 1 2 After the attapulgite of methanol solution is naturally dried, it is placed in a roasting furnace, 2 Under the atmosphere, the temperature was raised to 300°C at a rate of 3°C / min, and the mixture was calcined at a constant temperature for 2h and cooled to obtain an attapulgite-based C22-cycloaliphatic triester synthesis catalyst.

Embodiment 2

[0027] 1. Dry the bentonite, and determine the specific pore volume of the bentonite to be 1.12mL / g by the water adsorption weighing method; weigh 10kg of the dried bentonite to prepare ZnCl 2 11.2L of ethanol solution with a concentration of 1.0mol / L; while stirring the bentonite, add the ZnCl 2 Spray all ethanol solution evenly on the bentonite;

[0028] 2. To be impregnated with ZnCl as described in step 1 2 After the bentonite in the ethanol solution is naturally dried, it is placed in a roasting furnace, 2 Under the atmosphere, the temperature is increased to 300°C at a rate of 8°C / min, and the mixture is calcined at a constant temperature for 8 hours and cooled to obtain a bentonite-based C22-cycloaliphatic triester synthesis catalyst.

Embodiment 3

[0030] 1. Dry the kaolin, and determine the specific pore volume of the kaolin to be 1.02mL / g by the water adsorption weighing method; weigh 10kg of the dried kaolin to prepare ZnCl 2 10.2L of methanol solution with a concentration of 0.5mol / L; while stirring the kaolin, add the ZnCl 2 Spray the methanol solution on the kaolin all and evenly;

[0031] 2. To be impregnated with ZnCl as described in step 1 2 After the kaolin in methanol solution is naturally dried, it is placed in a roasting furnace, 2 In the atmosphere, the temperature is raised to 250°C at a rate of 5°C / min, and the catalyst is calcined at a constant temperature for 4h and cooled to obtain a kaolin-based C22-cycloaliphatic triester synthesis catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com