Preparation method and applications of zinc oxide-graphene oxide composite nanomaterial

A graphene composite and nanomaterial technology, which is applied in the preparation and application of nanomaterials, and the preparation and application of nanocomposite materials, can solve the problems of unsatisfactory antibacterial effect, other cell damage, weakened antibacterial ability, etc., and achieves inhibition of the growth of Escherichia coli , high antibacterial activity, simple and feasible operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the present embodiment, the steps of the preparation method of zinc oxide-graphene oxide composite nanomaterial are as follows:

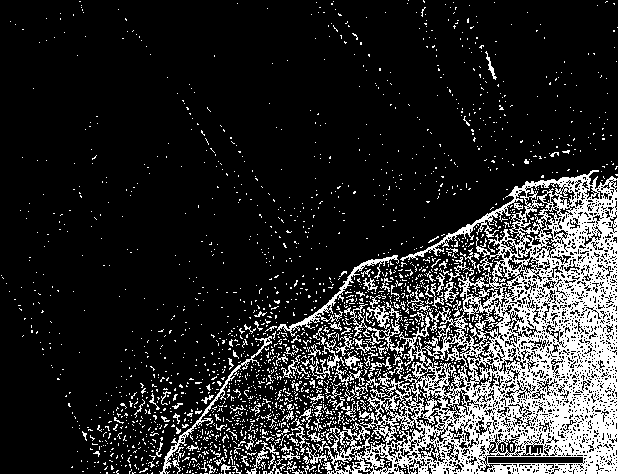

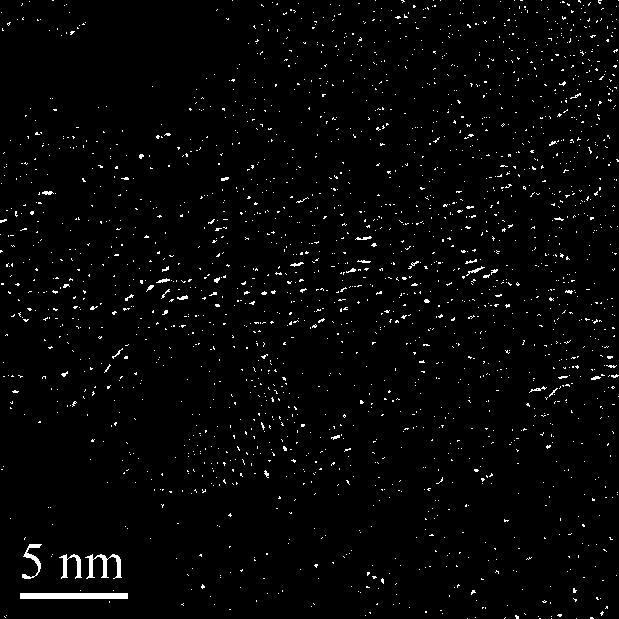

[0032] Use absolute ethanol as a solvent to form a reaction solution mixed system: that is, weigh 0.0025mol of Zn(Ac) 2 2H 2 O was dispersed in 50 mL of absolute ethanol to form a zinc source, and the reaction was vigorously stirred at 80°C for 20 minutes. At the same time, GO was prepared by Hummer’s oxidation method, weighing 0.2g LiOH·2H 2 O and 60mgGO were respectively dispersed in 20mL and 30mL of absolute ethanol, and the two were mixed under vigorous stirring, and the mixed solution was added dropwise to the zinc acetate mixed solution, and the stirring reaction was continued for 30 minutes. The OH that is gradually ionized by the LiOH lye in the reaction solution mixed system - with Zn 2+ The Zn-OH complex is formed, and then fully contacted with the oxygen-containing groups of GO to bind to the surface of GO. The reaction solu...

Embodiment 2

[0035] This embodiment is basically the same as Embodiment 1, especially in that:

[0036] In the present embodiment, the steps of the preparation method of zinc oxide-graphene oxide composite nanomaterial are as follows:

[0037] Weigh 0.0025mol of Zn(Ac) 2 2H 2 O was dispersed in 50 mL of absolute ethanol, and the reaction was vigorously stirred at 80°C for 20 minutes. At the same time, GO was prepared by Hummer’s oxidation method, weighing 0.2g LiOH·2H 2 O and 60mgGO were dispersed in 20mL and 30mL of absolute ethanol respectively, and the two were mixed under vigorous stirring, and the mixture was added dropwise into the zinc acetate mixed solution, and the reaction was continued for 1h. After the reaction was completed, after cooling to room temperature, n-hexane equivalent to twice the volume of the mixture was added, and placed in a refrigerator at 4° C. to settle overnight. After discarding the supernatant, the substrate was thoroughly washed three times with absol...

Embodiment 3

[0040] This embodiment is basically the same as the previous embodiment, and the special features are:

[0041] In this embodiment, weigh 0.0025mol of Zn(Ac) 2 2H 2 O was dispersed in 50 mL of absolute ethanol, and the reaction was vigorously stirred at 80°C for 20 minutes. At the same time, GO was prepared by Hummer’s oxidation method, weighing 0.2g LiOH·2H 2 O and 60mgGO were respectively dispersed in 20mL and 30mL of absolute ethanol, and the two were mixed under vigorous stirring, and the mixture was added dropwise into the zinc acetate mixed solution, and the reaction was continued for 5h. After the reaction was completed, after cooling to room temperature, n-hexane equivalent to twice the volume of the mixture was added, and placed in a refrigerator at 4° C. to settle overnight. After discarding the supernatant, the substrate was thoroughly washed three times with absolute ethanol and deionized water, and dried in a vacuum oven at 60 °C. For structural and performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com