Preparation method of polystyrene microspheres with casein supported on surface

A technology of polystyrene microspheres and surface loading, which is applied in the preparation of microspheres and microcapsule preparations, and can solve the problems of desorption, limited adsorption capacity, troublesome use of microspheres, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

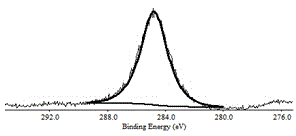

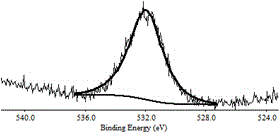

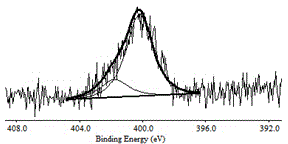

Image

Examples

Embodiment

[0028] A method for preparing polystyrene microspheres loaded with casein on the surface includes the following steps:

[0029] (1) Add 1.5g casein and 0.05g sodium carbonate to 50ml deionized water, dissolve at 50℃ under stirring, adjust the pH of the solution to 7.8 with 0.1M hydrochloric acid;

[0030] (2) Dissolve 0.1g of benzoyl peroxide (BPO) in a mixture of 11.4g of styrene and 0.6g of divinylbenzene;

[0031] (3) Put the above two components into a three-necked flask with stirring, and stir for 20 minutes to form an O / W white emulsion;

[0032] (4) Slowly raise the temperature to 72°C to carry out the polymerization reaction. The reaction time is 5 hours. During the reaction, the monomer droplets gradually become solid microspheres and partially encapsulate the hydrophobic segments of casein embedded on the surface to realize the loading of macromolecules;

[0033] (5) After the reaction, the microspheres are filtered or centrifuged, washed with deionized water for three times, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com