Hydrogel capable of loading high-hydrophobicity drug as well as preparation method and application of hydrogel

A hydrogel and drug technology, applied in the field of hydrogel that can load highly hydrophobic drugs and its preparation, can solve problems such as incompatibility, and achieve the effects of easy separation, mild reaction conditions, and stable capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

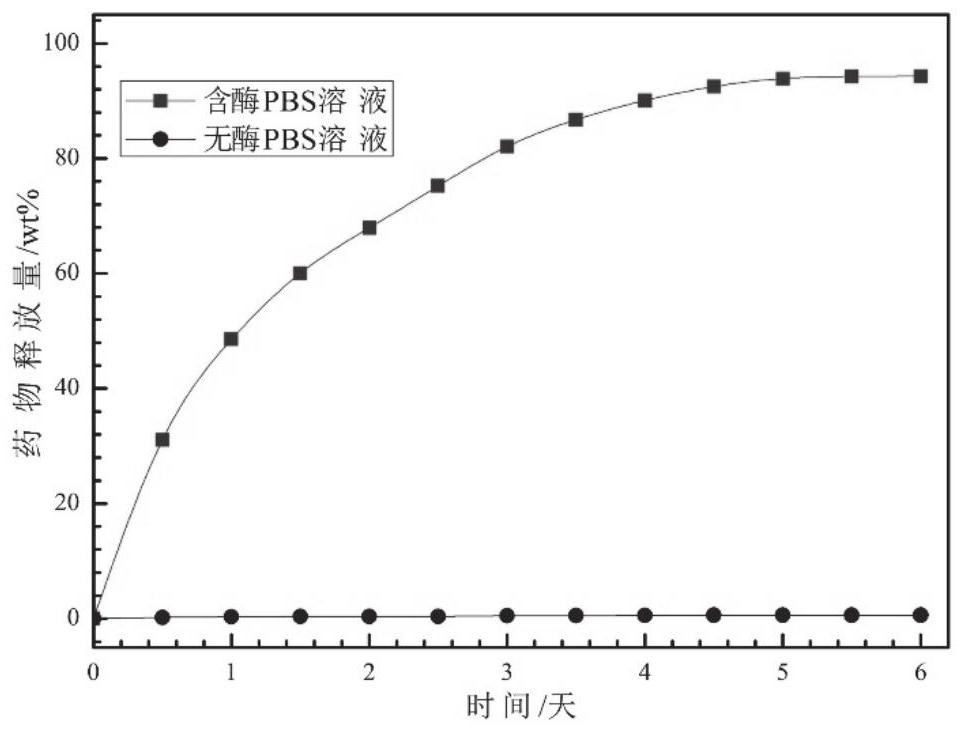

Problems solved by technology

Method used

Image

Examples

preparation example Construction

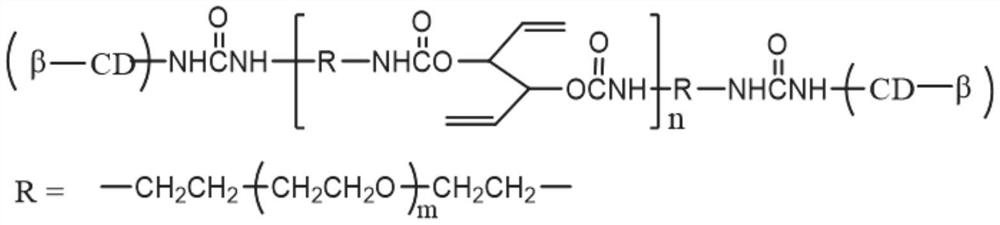

[0039] In another specific embodiment of the present invention, the preparation method of the above-mentioned cyclodextrin-terminated side chain double bond-containing polyurethane (DPU) is provided, the preparation method comprising:

[0040] The isocyanato-terminated polyethylene glycol is first reacted with 1,5-hexadiene-3,4-diol to prepare the isocyanato-terminated polyurethane prepolymer containing double bonds in the side chain, and then reacted with mono-6- O-amino-β-cyclodextrin reacts to obtain DPU by capping;

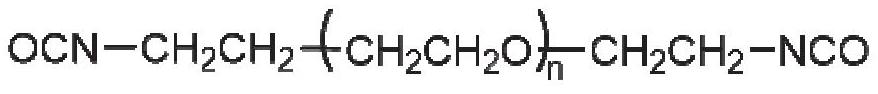

[0041] Wherein, the molecular structural formula of the isocyanato-terminated polyethylene glycol is as follows:

[0042]

[0043] In yet another specific embodiment of the present invention, the molecular weight of the above-mentioned isocyanato-terminated polyethylene glycol is controlled to be 3000-12000;

[0044] In yet another specific embodiment of the present invention, the molar ratio of 1,5-hexadiene-3,4-diol to isocyanato-terminated polyethylene gl...

Embodiment 1

[0074] Preparation of polyurethane: Dissolve 90.00g of double-terminated isocyanatopolyethylene glycol (molecular weight: 3000g / mol), 1.71g of 1,5-hexadiene-3,4-diol and 0.18g of stannous octoate in 200mL N , In N-dimethylformamide (DMF), heat the oil bath to 75°C to a constant temperature reaction until the -NCO content measured by the di-n-butylamine method reaches the theoretical value, about 3.5h. After cooling to 15°C, add 34.02g of mono-6-O-amino-β-cyclodextrin, maintain the temperature and react until the infrared absorption peak of isocyanate in the detection system disappears, about 2 hours. After the reaction is complete, when the system returns to room temperature, add DMF solution to dilute the cyclodextrin-terminated side chain double bond-containing polyurethane to 0.05g / mL, and then settle with ten times the volume of glacial ether (-6-1°C). Suction filtration, normal temperature vacuum drying to constant weight, obtain the polyurethane (DPU 1 ).

[0075] Prep...

Embodiment 2

[0078] Preparation of polyurethane: Dissolve 90g of double-terminated isocyanatopolyethylene glycol (molecular weight: 3000g / mol), 2.05g of 1,5-hexadiene-3,4-diol and 0.18g of diisobutyltin dilaurate in 200mL In N,N-dimethylformamide (DMF), heat the oil bath to 75°C to constant temperature reaction until the -NCO content measured by the di-n-butylamine method reaches the theoretical value, about 3.5h. After cooling to 15°C, add 27.22g of mono-6-O-amino-β-cyclodextrin, maintain the temperature and react until the infrared absorption peak of isocyanate in the detection system disappears, about 2 hours. After the reaction was completed, the system returned to room temperature, and DMF solution was added to dilute the cyclodextrin-terminated side chain-containing polyurethane to 0.05g / mL, and then settled with ten times the volume of glacial ether (-6-1°C). filtered, and vacuum-dried at room temperature to constant weight to obtain a cyclodextrin-terminated side chain containing d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com