Steel fiber feeding and dispersing device and dispersing method

A technology of dispersing device and steel fiber, applied in the direction of selling raw material supply device, pretreatment control, etc., can solve the problems of uneven dispersion and low dispersion efficiency of steel fiber, and achieve the effect of uniform dispersion, high efficiency and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

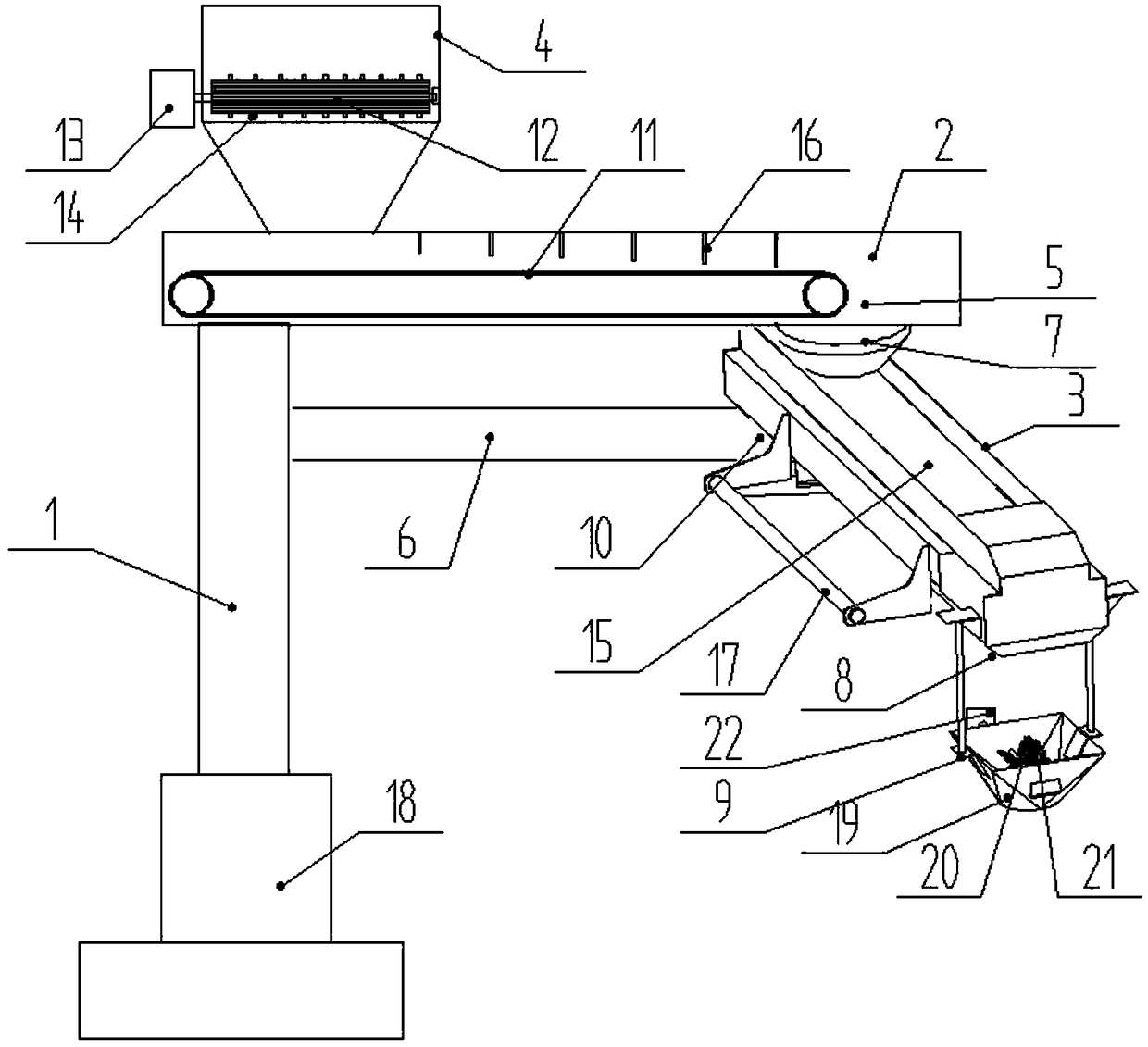

[0026] Such as figure 1 As shown, a kind of steel fiber feeding dispersing device of the present invention comprises dispersing support column 1, steel fiber conveying dispersing arm 2 and steel fiber rotating rocker 3, and described steel fiber conveying dispersing arm 2 is provided with feeding conveyer belt 11, so The bottom surface of one end of the steel fiber conveying dispersing arm 2 is arranged on the upper end of the dispersing support column 1, a dispersing hopper 4 is arranged on the end, and the bottom surface of the other end of the steel fiber conveying dispersing arm 2 is provided with a discharge port 5;

[0027] The dispersing hopper 4 is provided with a lowering cage 12, and the lowering cage 12 is driven to rotate by the lowering cage motor 13 arranged outside the dispersing hopper 4, and scraping target teeth are randomly arranged on the ribs of the lowering cage 12. 14. Continuously rotate the blanking cage 12, and place piles of steel fibers on the upper...

Embodiment 2

[0037] Such as figure 1 Shown, a kind of steel fiber feeding dispersion method of the present invention comprises steps:

[0038] Step 1. A conveying conveyor belt 11 is provided in the steel fiber conveying and dispersing arm 2. The bottom surface of one end of the steel fiber conveying and dispersing arm 2 is arranged on the upper end of the dispersing support column 1. A dispersing hopper 4 is arranged on the end, and the steel fiber conveying and dispersing The bottom surface of the other end of the arm 2 is provided with a discharge port 5;

[0039] Step 2, a blanking cage 12 is provided in the dispersion hopper 4, and the blanking cage 12 is driven to rotate by a blanking cage motor 13 arranged outside the dispersion hopper 4, and a scraper is arranged on the ribs of the blanking cage 12 in disorder The target teeth 14 are constantly rotating in the lower material cage 12, and the piles of steel fibers placed on the upper part of the lower material cage 12 are continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com