Control device for internal combustion engine

A control device and internal combustion engine technology, applied in engine control, internal combustion piston engine, electrical control, etc., can solve the problem of slowing down of throttle valve closing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be described below with reference to the drawings.

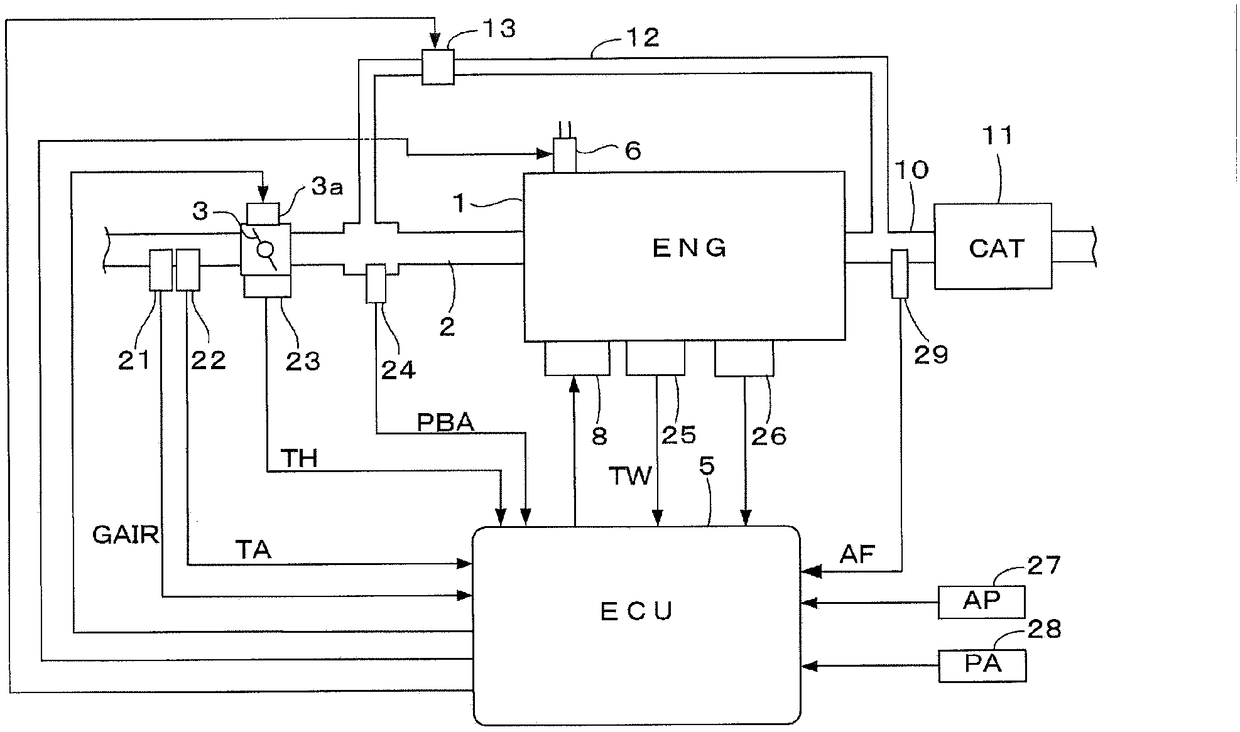

[0043] figure 1It is a diagram showing the structure of an internal combustion engine and its control device according to an embodiment of the present invention. The internal combustion engine (hereinafter referred to as "engine") 1 shown in the figure has, for example, four cylinders, and a direct combustion engine is provided in each cylinder. Injector 6 for injecting fuel in the chamber. The operation of the injector 6 is controlled by an electronic control unit (hereinafter referred to as “ECU”) 5 . In addition, a spark plug 8 is attached to each cylinder of the engine 1 , and the ignition timing of the spark plug 8 is controlled by the ECU 5 . A throttle valve 3 is arranged on an intake passage 2 of the engine 1 .

[0044] The following components are connected to the ECU5: the intake air flow sensor 21, which detects the intake air flow GAIR of the engine 1; the intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com