A radial loading device for an experimental platform for bearing performance testing

A technology for testing experiments and bearing performance, applied in mechanical bearing testing, measuring devices, testing of mechanical components, etc., can solve problems such as insufficient cognition, and achieve the effects of simple and compact structure, convenient disassembly and assembly, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

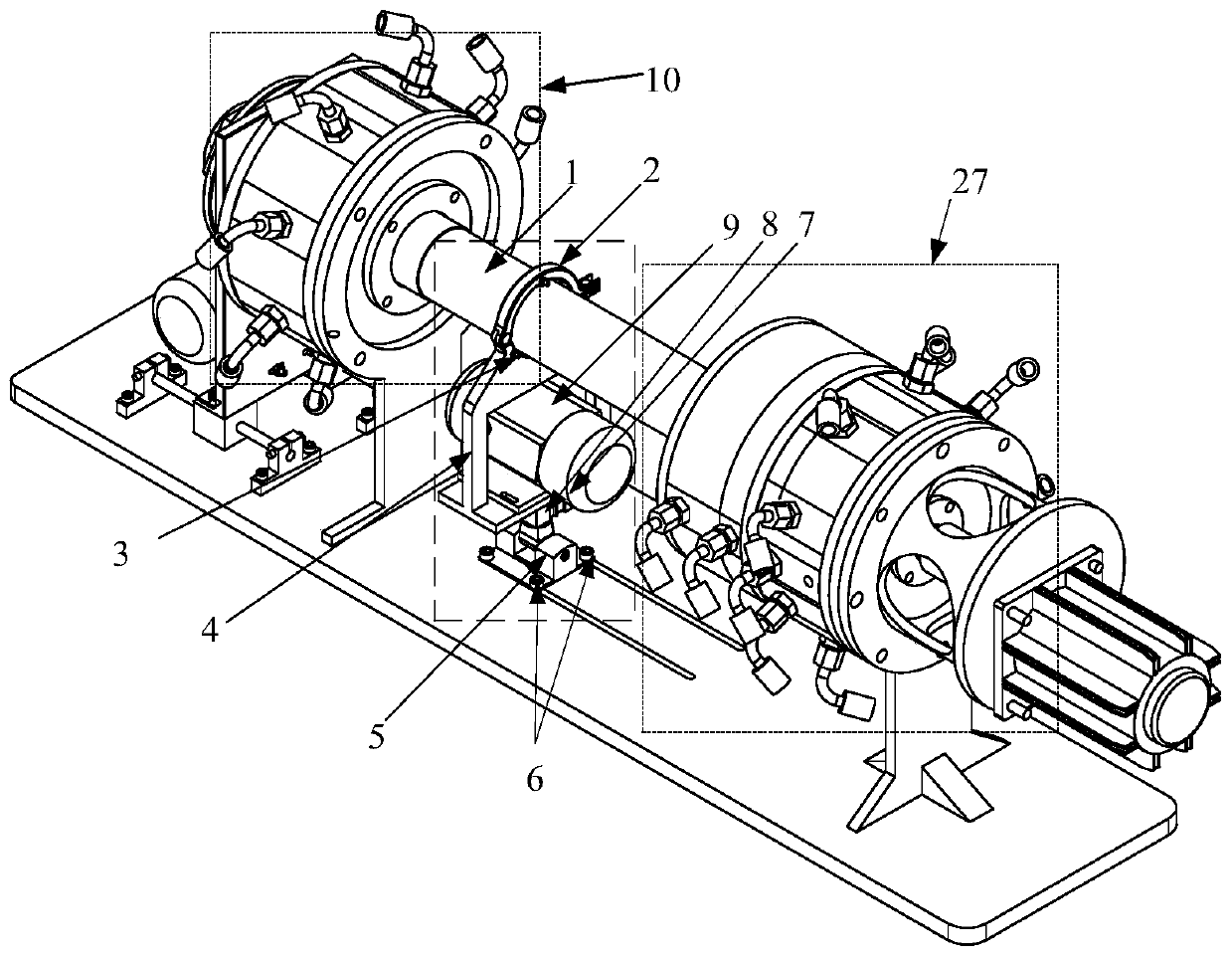

[0020] exist figure 1 In the three-dimensional schematic diagram of the radial loading device in use of the bearing performance testing experimental platform shown, radial magnetic fluid double suspension bearings 10 and composite magnetic fluid double suspension bearings are respectively arranged on both sides of the magnetic fluid double suspension bearing performance testing experimental platform. The suspension bearing 27 is provided with a stepped shaft 1 between the two. A radial loading device is provided on the platform corresponding to the stepped shaft.

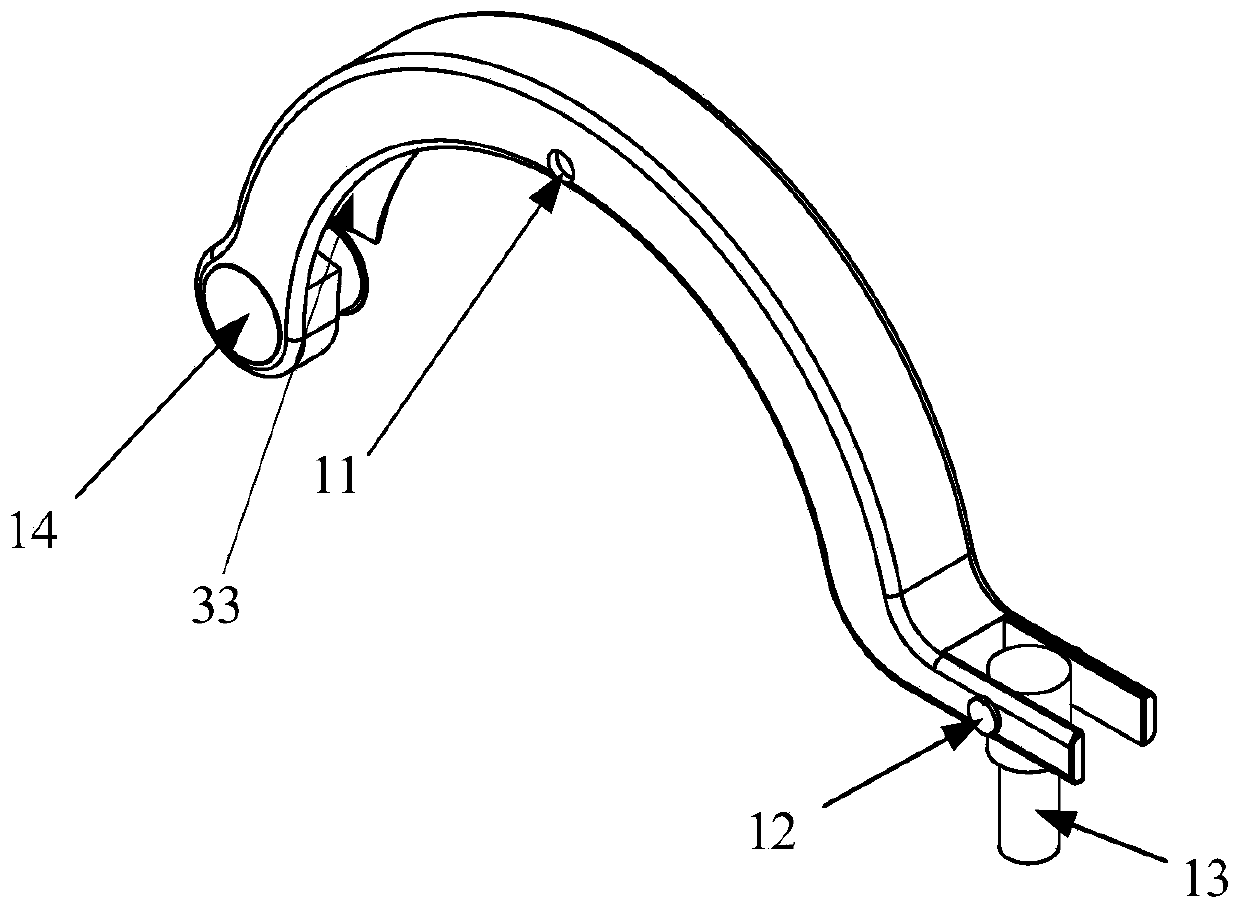

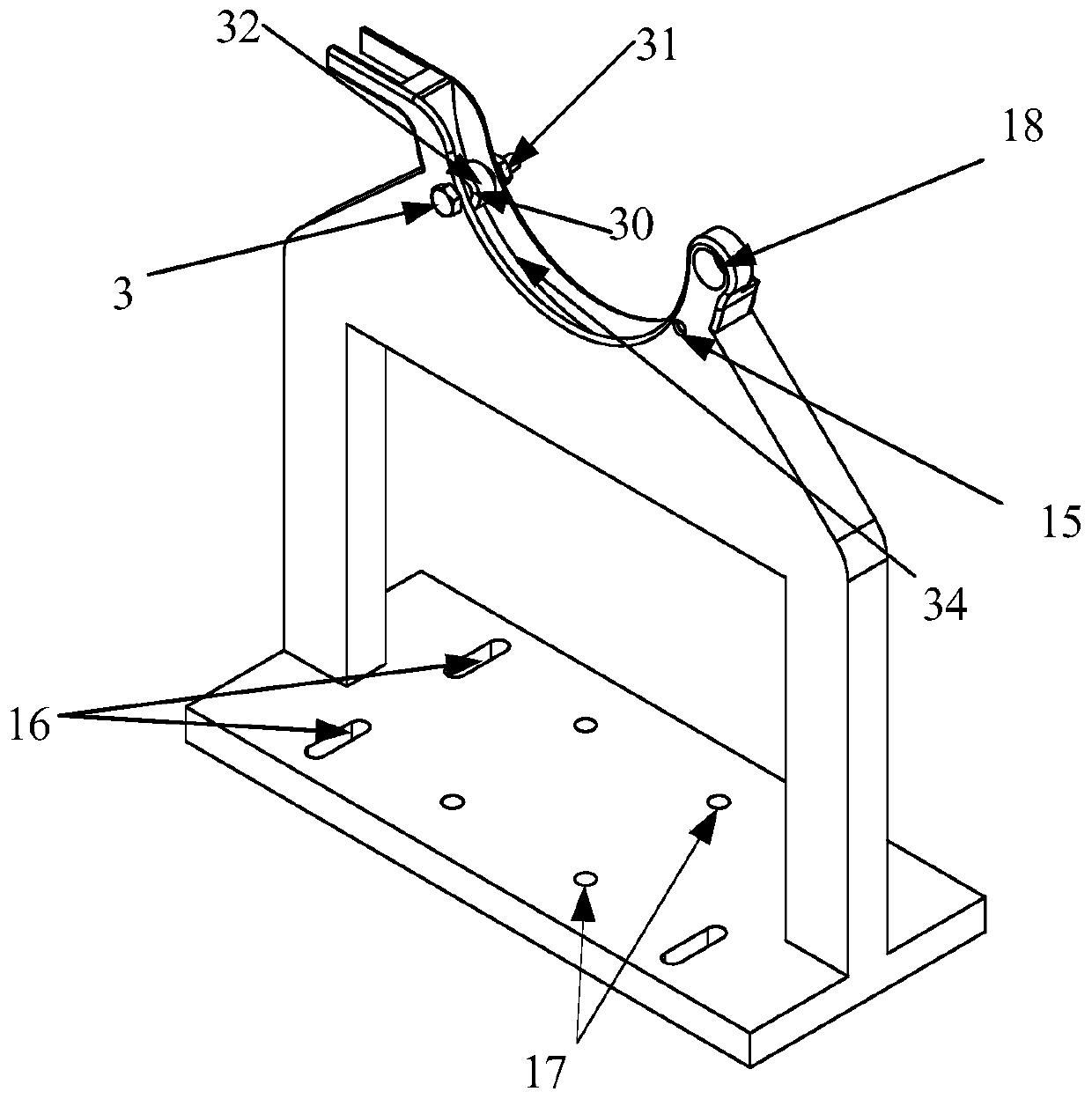

[0021] exist Figure 7 In the perspective schematic diagram of the radial loading mechanism of the present invention shown, the base frame of the radial loading device includes a base frame top cover 2 and a base frame main body 4 . pedestal top cover, such as figure 2 As shown, it is a semicircular rod 33 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com