A preparation method of fuel particles and core-shell fuel particles obtained therefrom

A technology of fuel particles and coated particles, which is applied in the direction of reactor fuel materials, nuclear engineering, nuclear power generation, etc., can solve the problem that the layer of combustible neutron poison cannot be easily coated, so as to reduce the risk of amoeba effect and prolong the reactor life. Run time, avoidance of reaction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

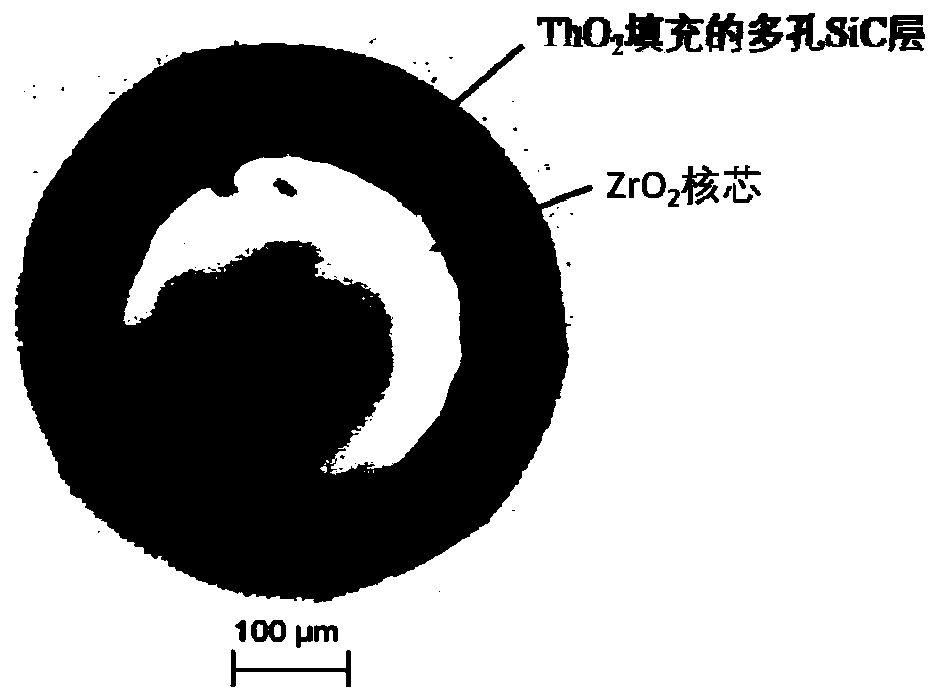

[0025] Example 1 ZrO 2 / PSiC-ThO 2 Preparation of core-shell fuel particles

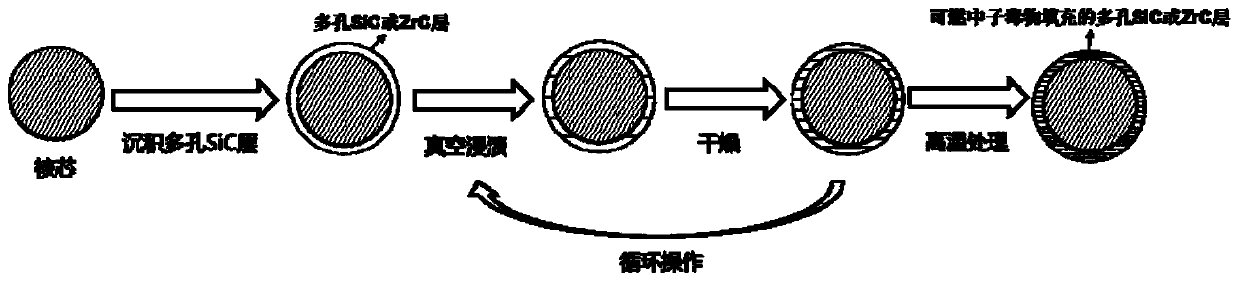

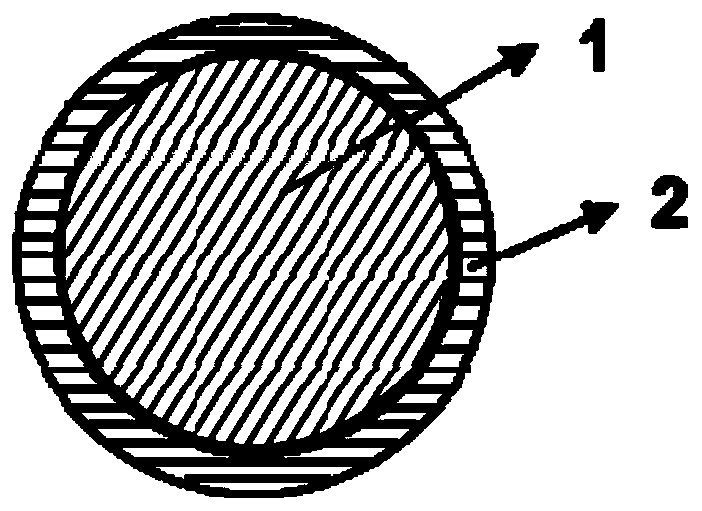

[0026] Such as figure 1 Shown, the preparation method according to the fuel particle of the present invention comprises the steps:

[0027] 1. Core preparation: choose ZrO with a diameter of 500 μm 2 Microspheres serve as cores.

[0028]2. Preparation of porous silicon carbide layer: argon gas is introduced into the high-temperature fluidized bed chemical vapor deposition device, and the above-mentioned prepared ZrO 2 Microspheres, the temperature rises to 1500 °C, and a mixture of argon, hydrogen, propylene and trichloromethylsilane (MTS) is introduced, wherein the molar ratio of trichloromethylsilane to propylene is 1:0.6, and hydrogen is used as a carrier. With gas, the deposition rate is 0.6 μm / min, and a composite layer containing silicon carbide and carbon is obtained. The above sample was placed in a high-temperature furnace, heated to 850° C. under an air atmosphere, and kept for 5 hour...

Embodiment 2

[0031] Example 2 PuO 2 / PZrC-ThO 2 Preparation of core-shell fuel particles

[0032] The specific process steps are as follows:

[0033] 1. Core preparation: choose PuO with a diameter of 500 μm 2 Microspheres serve as cores.

[0034] 2. Preparation of porous zirconium carbide layer: the above PuO 2 The microspheres are loaded into a high-temperature fluidized bed chemical vapor deposition device, the temperature rises to 1100°C, and a mixed gas of hydrogen, zirconium chloride and methane is introduced, wherein the molar ratio of zirconium chloride and methane is 1:1.6, and hydrogen is used as Carrier gas, deposition rate 0.3 μm / min, to obtain a composite layer containing zirconium carbide and carbon. The above sample was placed in a high-temperature furnace, heated to 850° C. under an air atmosphere, and kept for 3 hours to remove carbon to obtain a 10 μm thick porous zirconium carbide layer (PZrC).

[0035] 3. Vacuum impregnation: Add ammonia water dropwise at a flow r...

Embodiment 3

[0037] Example 3 CeO 2 / pSiC-Lu 2 o 3 Preparation of core-shell fuel particles

[0038] The specific process steps are as follows:

[0039] 1. Core preparation: choose CeO with a diameter of 100 μm 2 Microspheres serve as cores.

[0040] 2. Preparation of porous silicon carbide layer: argon gas is introduced into the high-temperature fluidized bed chemical vapor deposition device, and the above prepared CeO 2 Microspheres, the temperature rises to 1400 ° C, and a mixture of argon, hydrogen, propylene and trichloromethylsilane (MTS) is introduced, wherein the molar ratio of trichloromethylsilane to propylene is 1:0.6, and hydrogen is used as a carrier. With gas, the deposition rate is 0.4 μm / min, and a composite layer containing silicon carbide and carbon is obtained. The above sample was placed in a high-temperature furnace, heated to 850° C. under an air atmosphere, and kept for 3 hours to remove carbon and obtain a 10 μm thick porous silicon carbide layer (PSiC).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com