A method, device and application of light-driven rapid preparation of membrane electrodes

A membrane electrode and light-driven technology, applied in the field of electrochemistry, can solve the problems of increasing membrane electrode preparation cost, complicated process, and expensive price, and achieve the effects of easy mass production of membrane electrodes, simple device structure, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

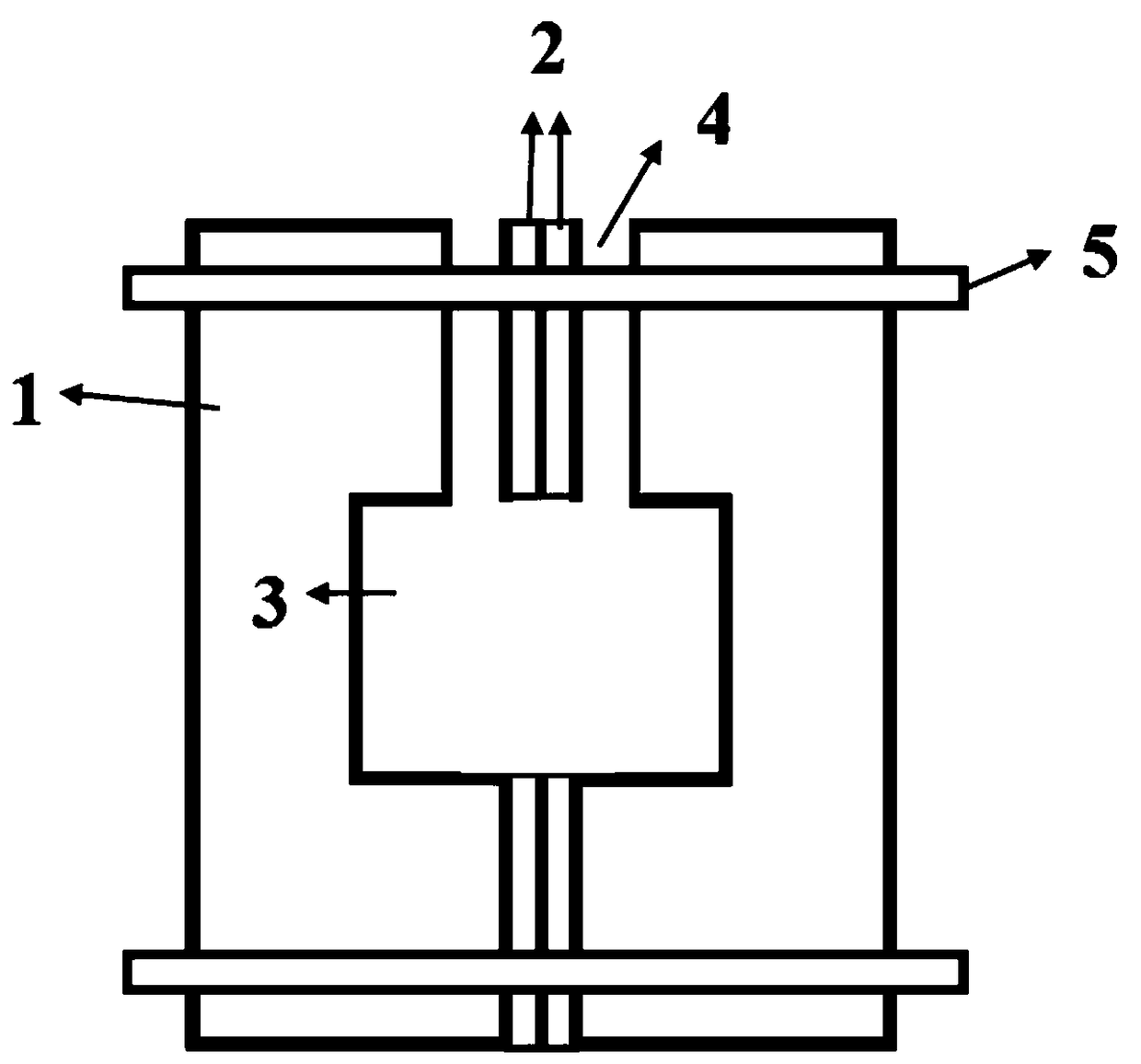

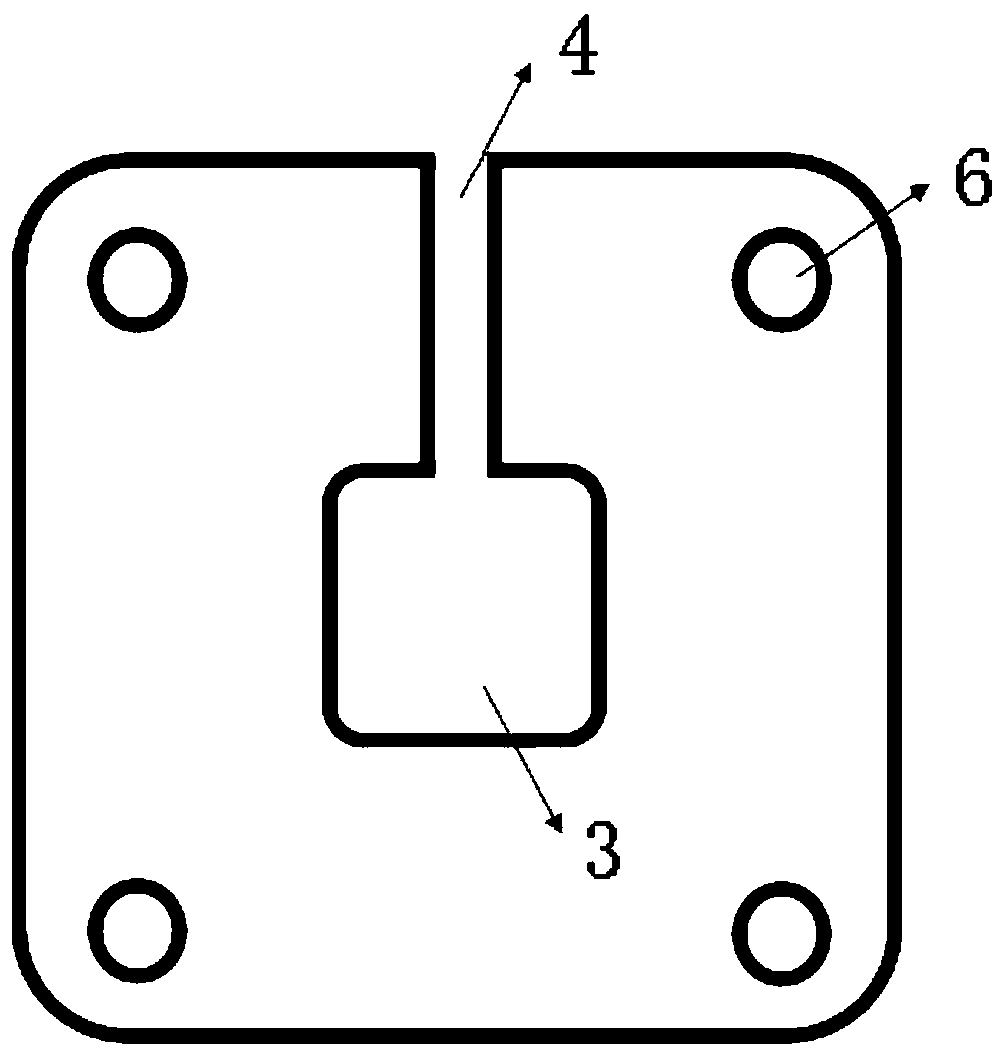

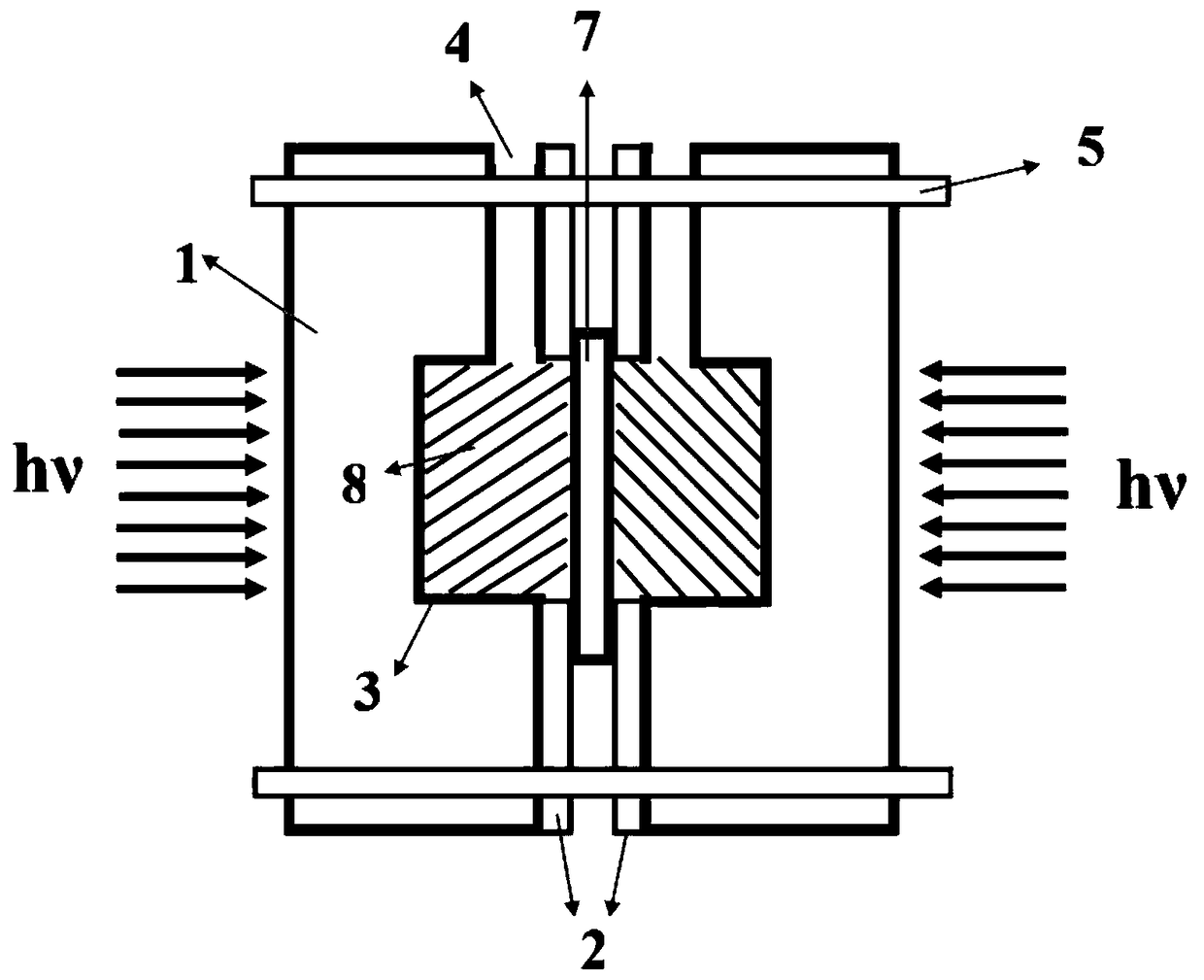

[0042] Take a 3.5×3.5cm Nafion115 membrane and soak it in octaethylzinc porphyrin alcohol solution (100 μM) for 5min to wash the excess octaethylzinc porphyrin on the membrane surface. Such as Figure 1~3 As shown, at room temperature, the Nafion membrane loaded with octaethylzinc porphyrin was fixed in two reaction pools 3 (the volume of the reaction pool 3 was 2×2×0.3cm) sealed with a silica gel gasket (sealing gasket 2) , tighten screw 5. Take 2mL K 2 PtCl 4 (20mM) aqueous solution and 2mL ascorbic acid (150mM) aqueous solution in a small bottle, after mixing, add 1.2mL of the reaction solution into the two reaction pools 3 through the feeding channel 4 respectively. The device was placed under a tungsten-halogen lamp (75V, light intensity 570nmol cm -2 the s -1 ) for 5 min, turn off the light source, let Pt grow, and obtain a membrane electrode.

[0043] The molecular structure of octaethyl zinc porphyrin is as follows Figure 5 shown. Figure 6 , 7 For the SEM el...

Embodiment 2

[0044] Example 2: (changing the lighting time)

[0045] Take a 3.5×3.5cm Nafion117 membrane (belonging to cation exchange membrane), soak it in octaethylzinc porphyrin alcohol solution (100μM) for 5min, such as Figure 1~3 As shown, at room temperature, fix the Nafion membrane loaded with octaethylzinc porphyrin between two reaction pools 3 (the volume of the reaction pool 3 is 2×2×0.3 cm) sealed with a silica gel gasket, and tighten the screws 5. Take 2mLK 2 PtCl 4 (20mM) aqueous solution and 2mL ascorbic acid (150mM) aqueous solution in a small bottle, after mixing, add 1.2mL of the reaction solution to the two reaction pools 3 through the feeding channel 4 respectively. The reaction system was placed under a tungsten halogen lamp (75V, the light intensity was 570nmolcm -2 the s -1 ) for 3 minutes, turn off the light source, take it out after 30 minutes, and obtain the membrane electrode.

[0046] The resulting membrane electrode is Figure 8 As shown in , the area of...

Embodiment 3

[0047] Embodiment 3: (change the kind of metal macrocyclic compound)

[0048] Take a 3.5×3.5cm Nafion117 membrane, soak it in 4(N-picoline) zinc porphyrin aqueous solution (100μM) for 5min, wash the excess 4(N-picoline) zinc porphyrin on the surface of the membrane . Such as Figure 1~3 As shown, at room temperature, the Nafion membrane loaded with 4 (N-picoline) zinc porphyrin was fixed in the two reaction pools 3 sealed with silica gel gaskets (the volume of the reaction pool 3 is 2×2×0.3cm) In between, tighten screw 5. Take 2mL K 2 PtCl 4 (20mM) aqueous solution and 2mL ascorbic acid (150mM) aqueous solution in a small bottle, after mixing, add 1.2mL of the reaction solution into the two reaction pools 3 through the feeding channel 4 . Place the device under a tungsten-halogen lamp (75V, light intensity 570nmol cm -2 the s -1 ) for 5 minutes, turn off the light source, let Pt grow, and obtain a membrane electrode.

[0049] The molecular structure of 4 (N-picoline) z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com