Graphene/calcium phosphate ceramic composite scaffold with antibacterial function and preparation method thereof

A technology of calcium phosphate ceramics and composite scaffolds, which is applied in the field of biomedical materials, can solve the problems of insufficient antibacterial performance, and achieve the effects of simple operation, scientific design and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses the preparation method of the graphene / calcium phosphate ceramic composite support of the present invention, specifically:

[0035] (1) Configure a graphene solution of 0.1 mg / ml, and immerse the porous biphasic calcium phosphate ceramics (mass ratio HA:β-TCP=3:7, porosity 62%) in the graphene solution;

[0036] (2) Transfer the graphene solution containing porous calcium phosphate ceramics to a suction filter bottle, vacuum infuse it for 10 minutes under the condition of a relative vacuum of -0.08MPa, take out the ceramics, dry at 60°C, and continue to put in graphene after drying Vacuum perfusion in the solution, drying, and repeating three times can obtain the graphene / calcium phosphate ceramic composite scaffold.

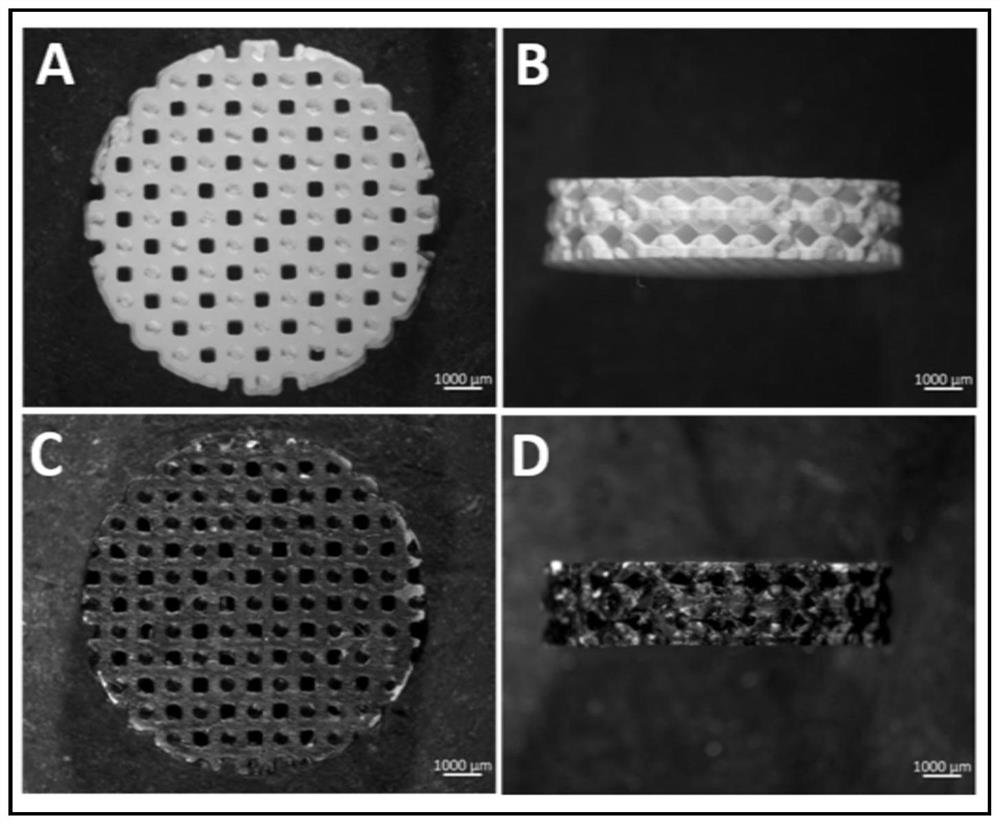

[0037] The stereomicrograph of the graphene / calcium phosphate ceramic composite support that the present embodiment makes is as attached figure 1 (C-D), with attached figure 1 (A–B) Compared with the unloaded calcium phosphate ...

Embodiment 2

[0039] This embodiment discloses the preparation method of the graphene / calcium phosphate ceramic composite support of the present invention, specifically:

[0040] (1) Configure a 1.0mg / ml graphene oxide solution, and immerse the porous hydroxyapatite ceramics (70% porosity) in the graphene oxide solution;

[0041] (2) Transfer the graphene oxide solution containing porous hydroxyapatite ceramics to a suction filter bottle, vacuum infuse it for 10 minutes under the condition of relative vacuum degree -0.04MPa, take out the ceramics, freeze-dry, and continue to put graphite oxide after drying The graphene / calcium phosphate ceramic composite scaffold can be obtained by vacuum perfusion in the graphene solution and freeze-drying.

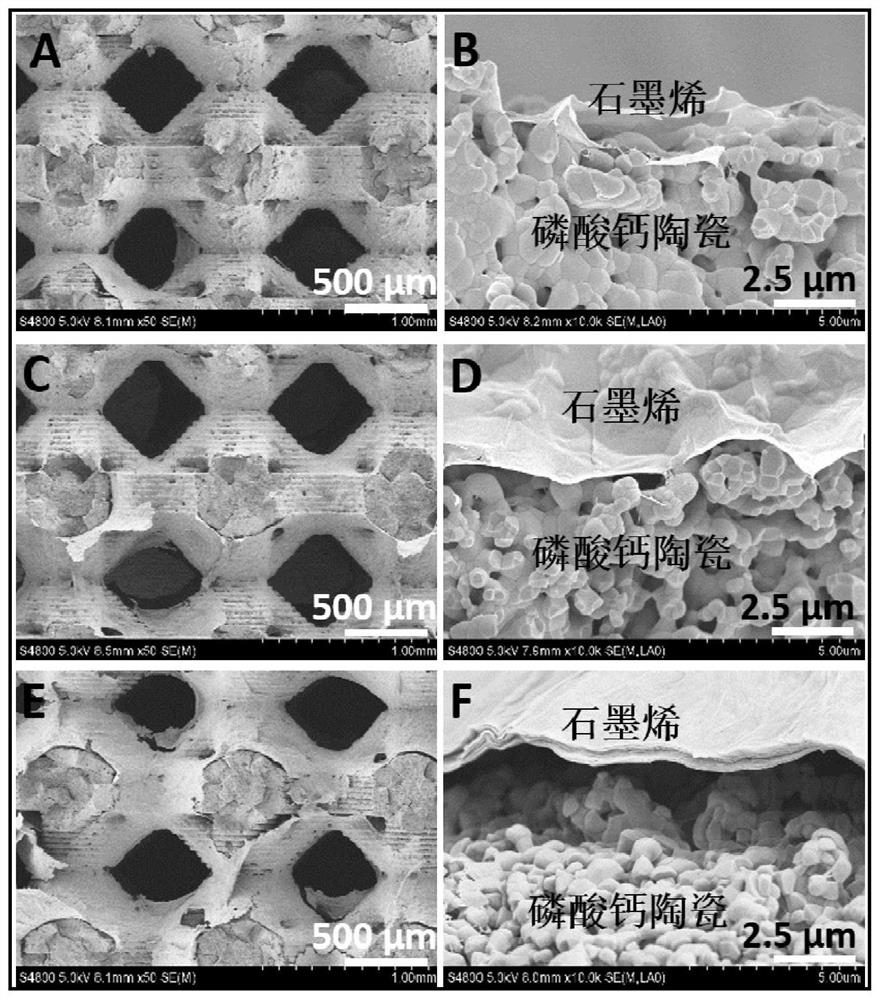

[0042] The microstructure of the graphene / calcium phosphate ceramic composite support prepared in this embodiment is as attached figure 2 As shown in (A-B), it can be found that there is a thin layer of graphene on the ceramic surface with a thickne...

Embodiment 3

[0044] This embodiment discloses the preparation method of the graphene / calcium phosphate ceramic composite support of the present invention, specifically:

[0045](1) Configure a reduced graphene oxide solution of 10 mg / ml, and immerse the porous tricalcium phosphate ceramics (42% porosity) in the reduced graphene oxide solution;

[0046] (2) Transfer the reduced graphene oxide solution containing porous tricalcium phosphate ceramics to a suction filter bottle, vacuum infuse it for 30 minutes under the condition of relative vacuum degree of -0.1MPa, take out the ceramics, freeze-dry, and continue to put in the reduction after drying The graphene / calcium phosphate ceramic composite scaffold can be obtained by vacuum pouring into the graphene oxide solution and freeze-drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com