Built-in implantation loading method and built-in loading device for small laboratory animal

A loading device and small-scale test technology, applied in medical science, surgery, etc., to achieve the effects of less error, less trauma, and smaller volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the drawings and implementation process.

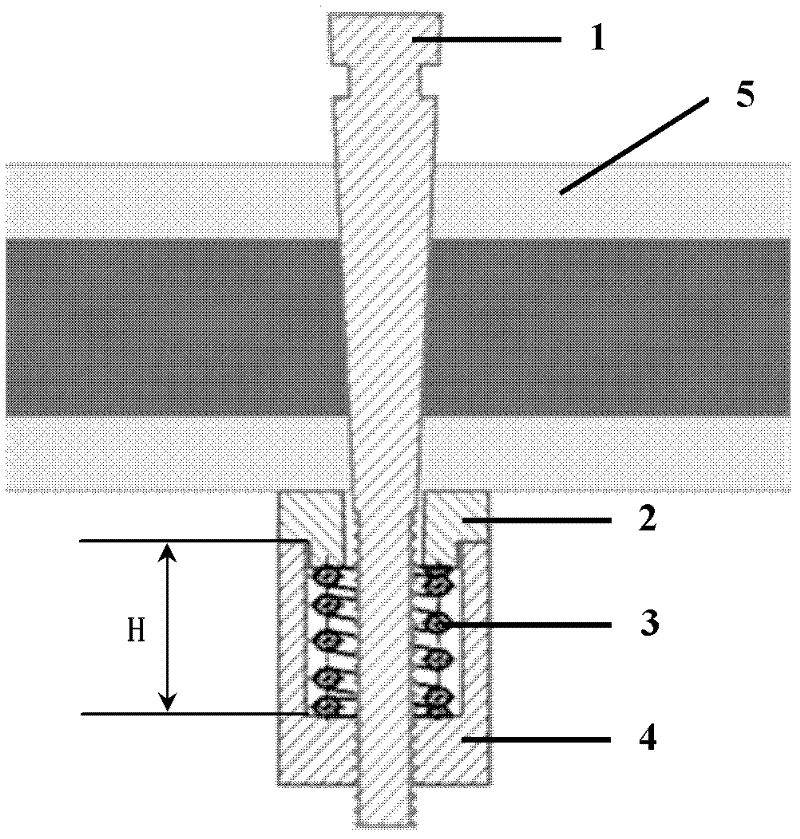

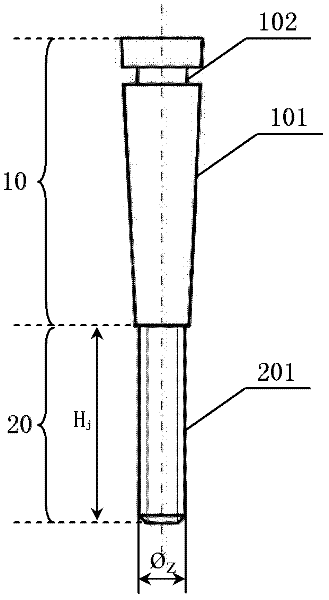

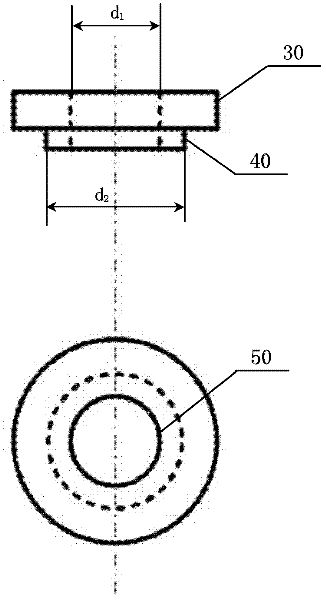

[0030] see figure 1, the present invention designs a kind of loading square suitable for the implantation experiment in the bone of small experimental animal and the built-in loading device used in this process, wherein the loading device consists of base body (1), spacer (2), compression spring (3) and retention cap (4) form. When carrying out animal experiments, the matrix is implanted from the outside of the femur or tibial backbone of the animal, runs through the entire bone cavity, and passes through the inner side of the backbone, while ensuring that the axis of the base (1) is basically perpendicular to the axis of the backbone. After the matrix (1) is implanted, install the spacer (2) and the spring (3) in sequence on the inside, and then screw the retaining cap (4) into the external thread (201) of the matrix (1) until it is retained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com