Electrode modified method for increasing degradation efficiency of PbO2 electrode

An electrode modification and electrode technology, which is applied in the direction of electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of inability to expand the range of visible light, reduce the conductivity of electrodes, and unfavorable electrode performance, and achieve wide application, easy implementation, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Example 1. First, according to the above method, 2.0g TiO was added to 200ml electrodeposition solution respectively. 2 , 1.0gTiO 2 and 1.0g MnO 2 , 2.0 g MnO 2 Microparticle Modified PbO 2 electrode to investigate TiO 2 In the presence of other photocatalysts such as MnO 2 Etc TiO 2 Promotion of photodegradation efficiency.

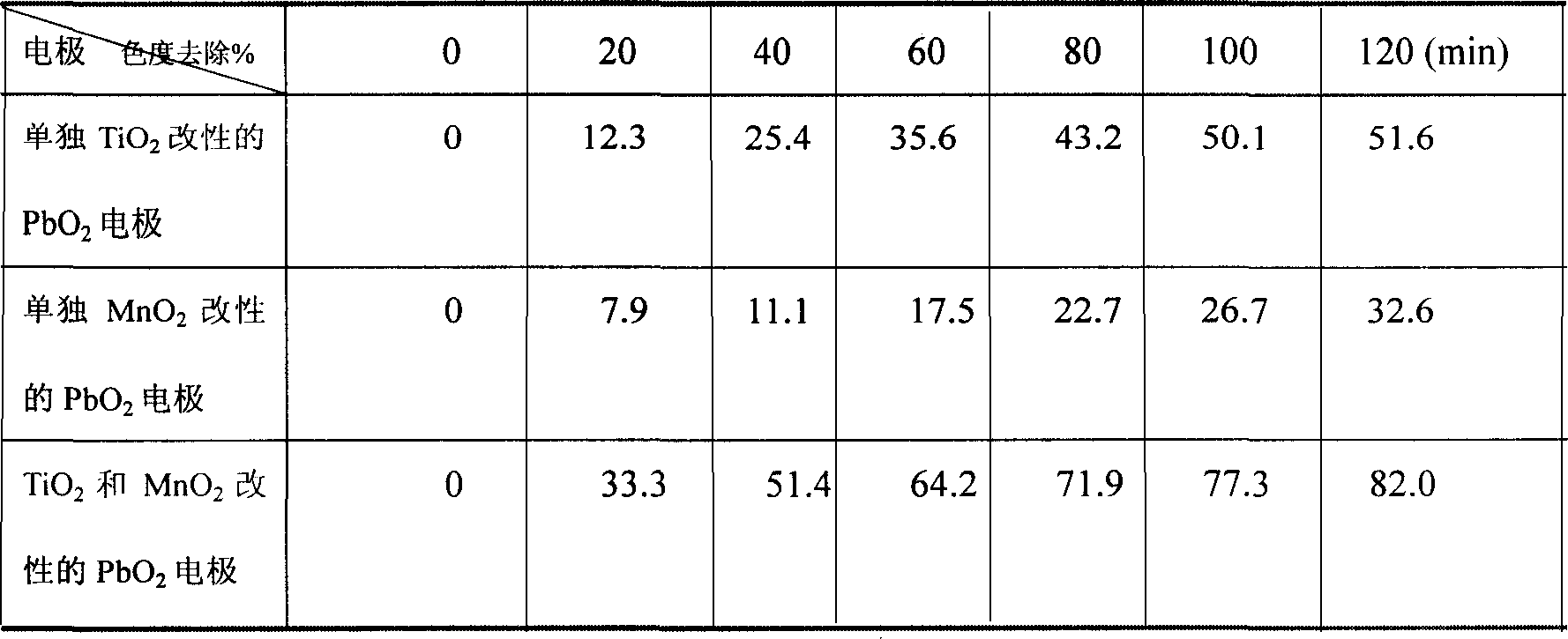

[0016] The measurement device is a semi-cylindrical quartz reactor, which will simultaneously fix TiO 2 The photoanode modified with other photocatalysts is fixed at 5mm on the flat side of the reactor, and the 8w ultraviolet lamp with a dominant wavelength of 254nm is fixed at a distance of 20mm from the quartz reactor. Table 1 shows the comparison results of several electrodes treated with 50 mg / L azo dye Acid Orange II solution for 120 minutes under an applied voltage of 1.5 V (between the photoelectrode and the counter electrode).

[0017] Chromaticity removal comparison when electrodes prepared in Table 1 are used for photodegradation...

example 2

[0019] Example 2, the electrode preparation method is the same as the coating and calcination method, and TiO is prepared 2 and MnO 2 co-modified PbO 2 electrode. It was used to simulate the catalytic degradation of 20 mg / L azo dye Acid Orange II under visible light, and other reaction conditions were the same as in Experimental Example 1. After 2 hours of reaction, the decolorization rate reaches 19.7%. If 1.5V voltage is applied between the cathode and anode, the decolorization rate reaches 35.2% after 2 hours of reaction.

example 3

[0020] Example 3, the electrode preparation method is the same as in Experimental Example 1, and a separate TiO 2 Modified PbO 2 Electrodes and TiO 2 and MnO 2 co-modified PbO 2 Electrode, used to degrade 50mg / L azo dye Acid Orange II, the supporting electrolyte is 0.01mol / L Na 2 SO 4 , a voltage of 4.0V was applied between the cathode and the anode, and other reaction conditions were the same as in Experimental Example 1. with TiO alone 2 Modified PbO 2 For electrodes, the TOC removal rate reaches 47.3% after 2 hours of reaction, and TiO 2 and MnO 2 co-modified PbO 2 The removal rate of TOC reached 56.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com