Milk frother

A milk and foaming technology, which is applied to cooking utensils, utensils with integral electric heating devices, beverage preparation devices, etc., can solve the problems of large volume, heavy equipment, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

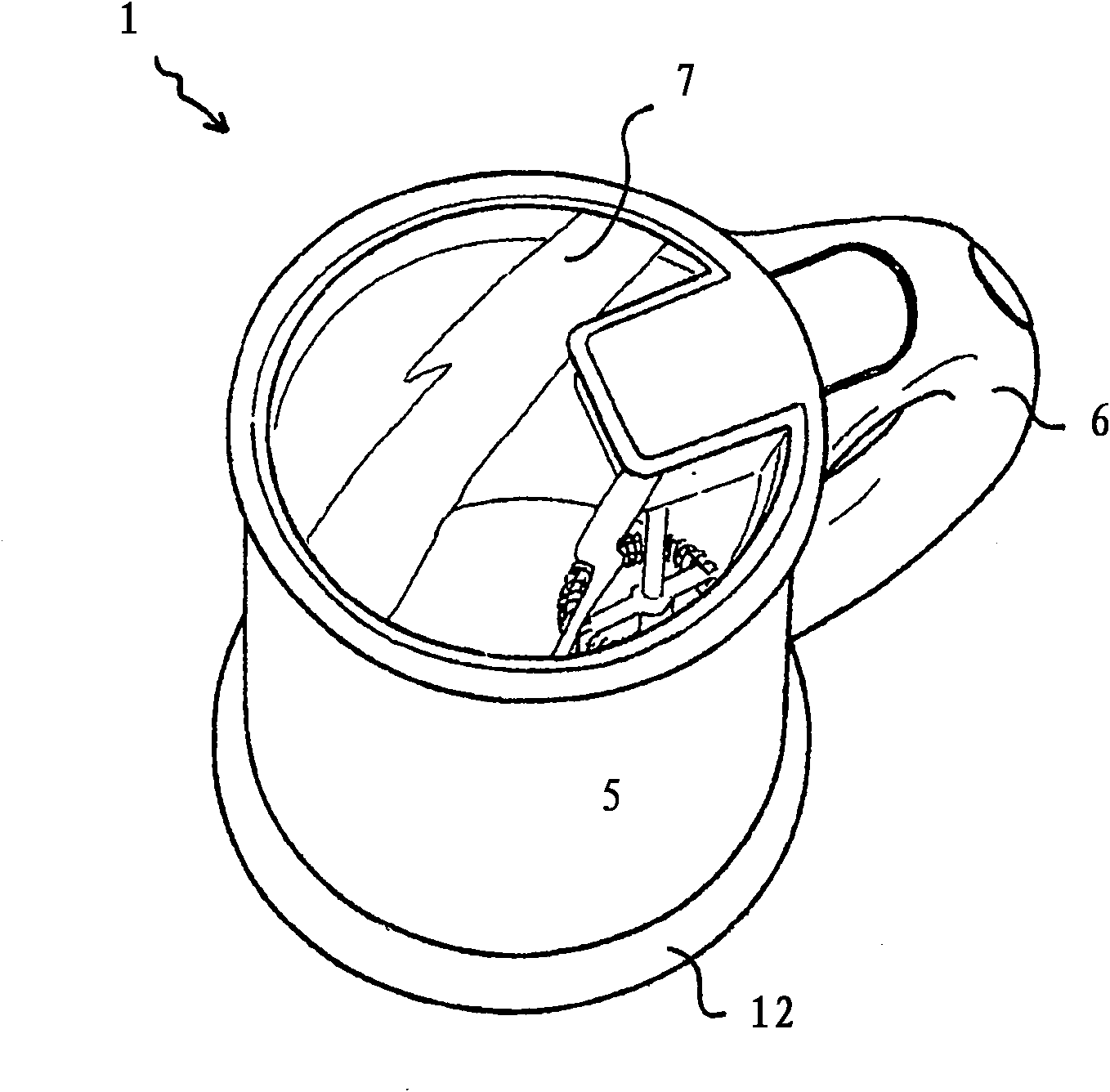

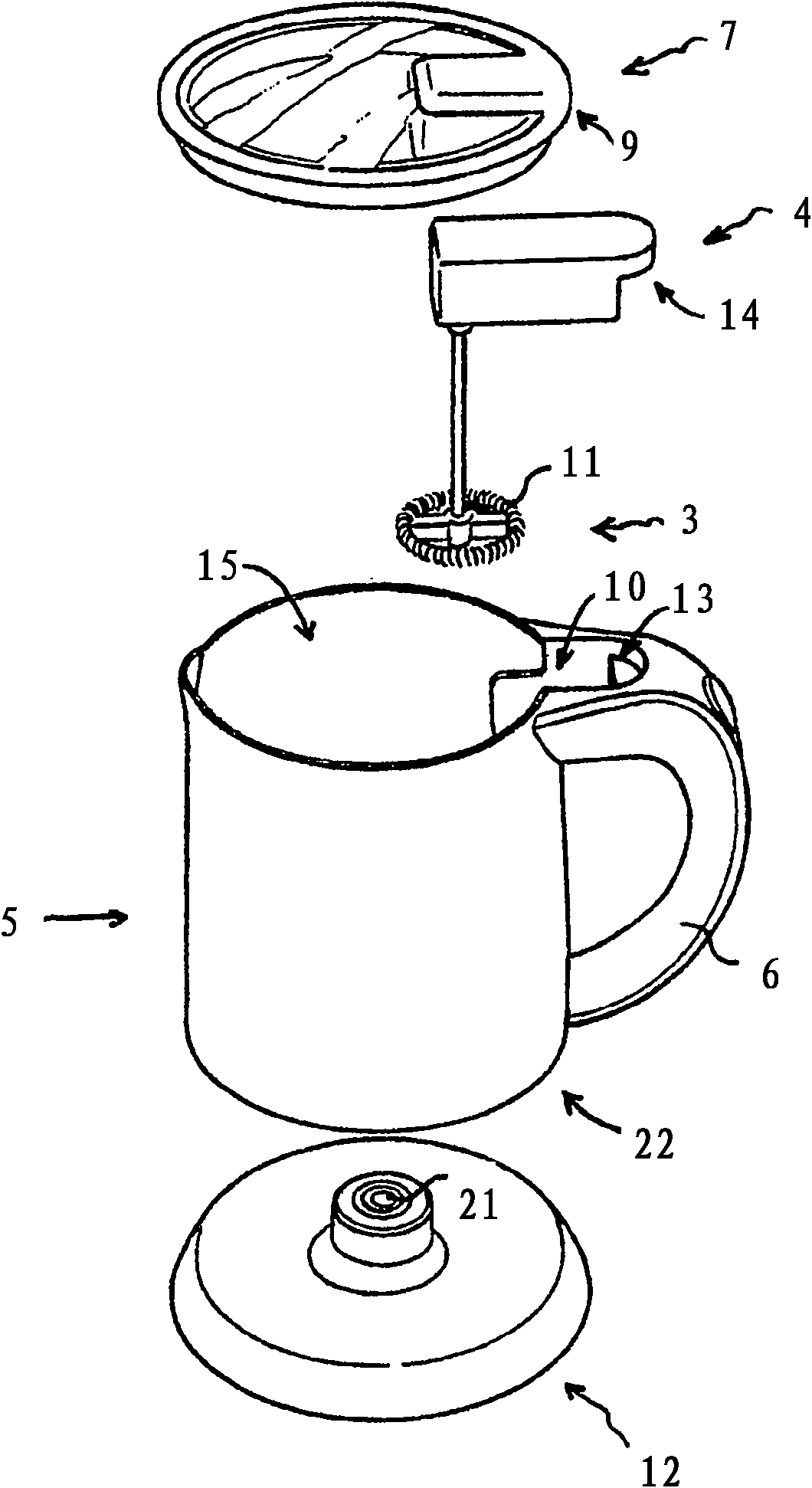

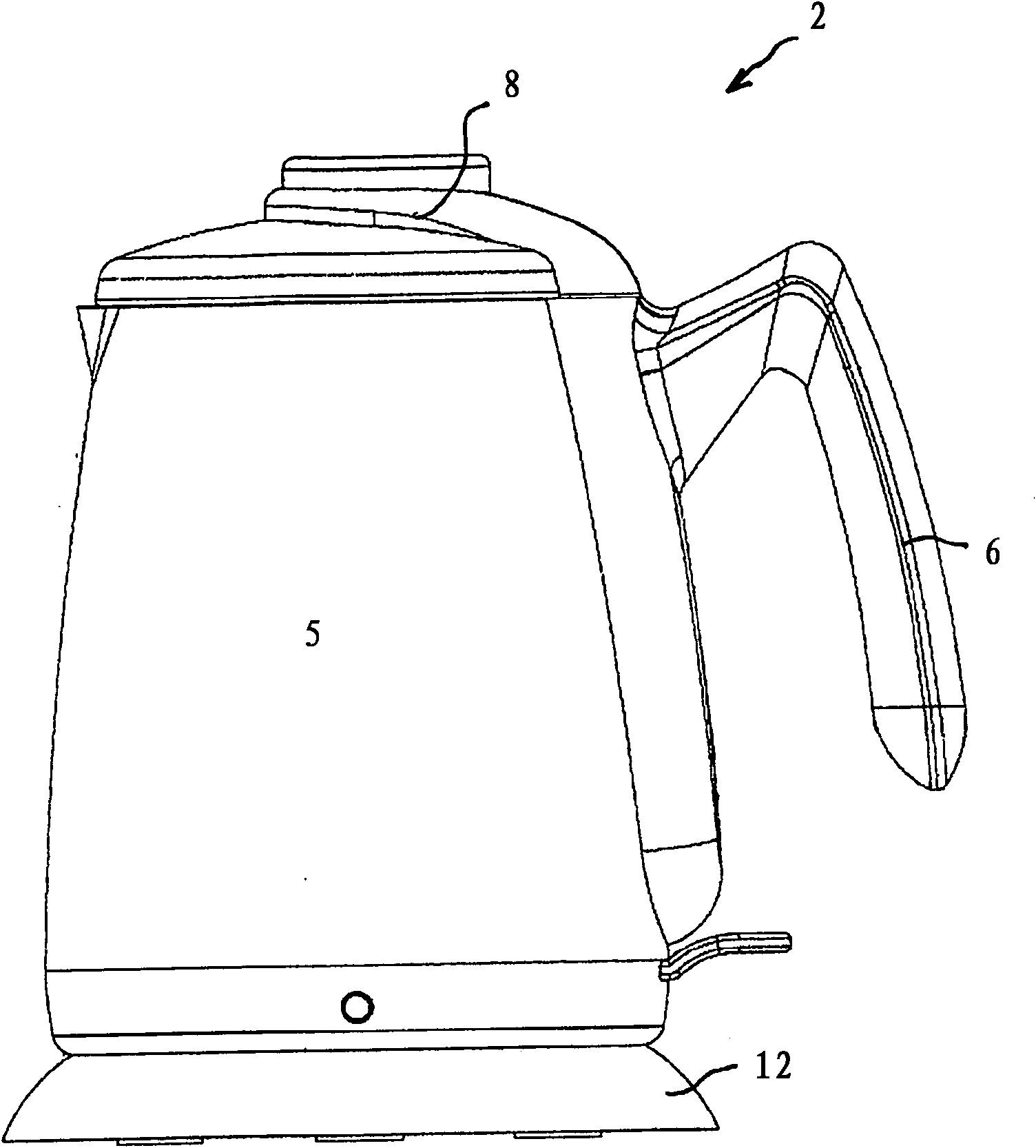

[0027] The devices 1, 2 shown in the figures each comprise a stirring mechanism 3 and a drive mechanism 4 for driving said stirring mechanism 3, in addition to a main body 5 forming a container 15 for milk, and an electrical conductor (not shown) is arranged in this body 5 . The main body 5 includes a handle 6 for facilitating the manipulation of the main body 5 . Each device 1 , 2 comprises a cover 7 , 8 fitted to the main body 5 , the covers 7 , 8 are loosely placed on the main body 5 in the example given, but they could also be hinged, for example. Ground is connected to body 5. The drive mechanism 4 is supplied with electrical energy via electrical conductors. To this end, between a base contact (also referred to as a first electrical contact) 21 on the base plate 12 and a lower body contact (also referred to as a second electrical contact) 22 (not shown) on the main body 5 and Also on the drive mechanism 4 a drive mechanism contact (also referred to as a third electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com