Underslung single camshaft engine decompression mechanism of motorcycle

A decompression mechanism, camshaft technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of large starting resistance, noise, short service life of the engine, etc., to achieve decompression function, simple structure, work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

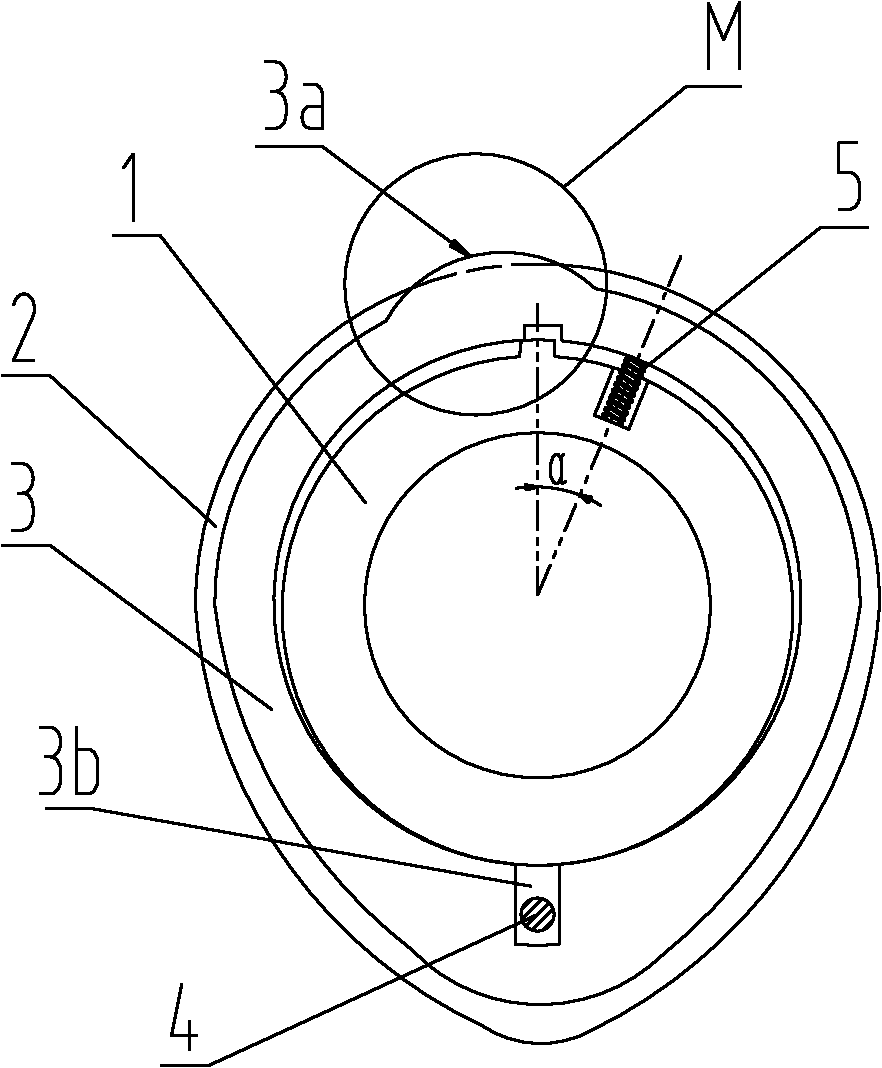

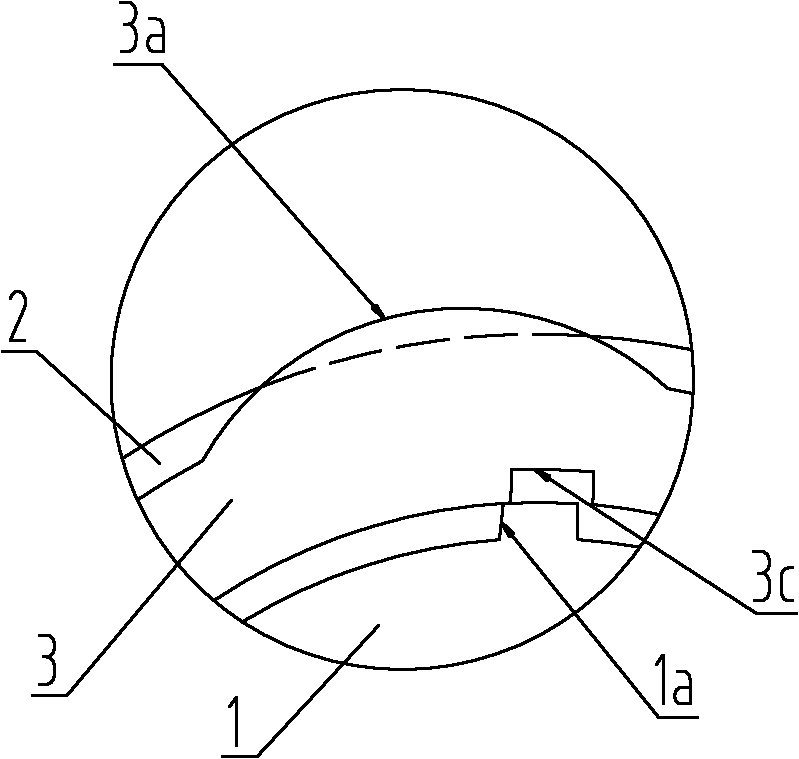

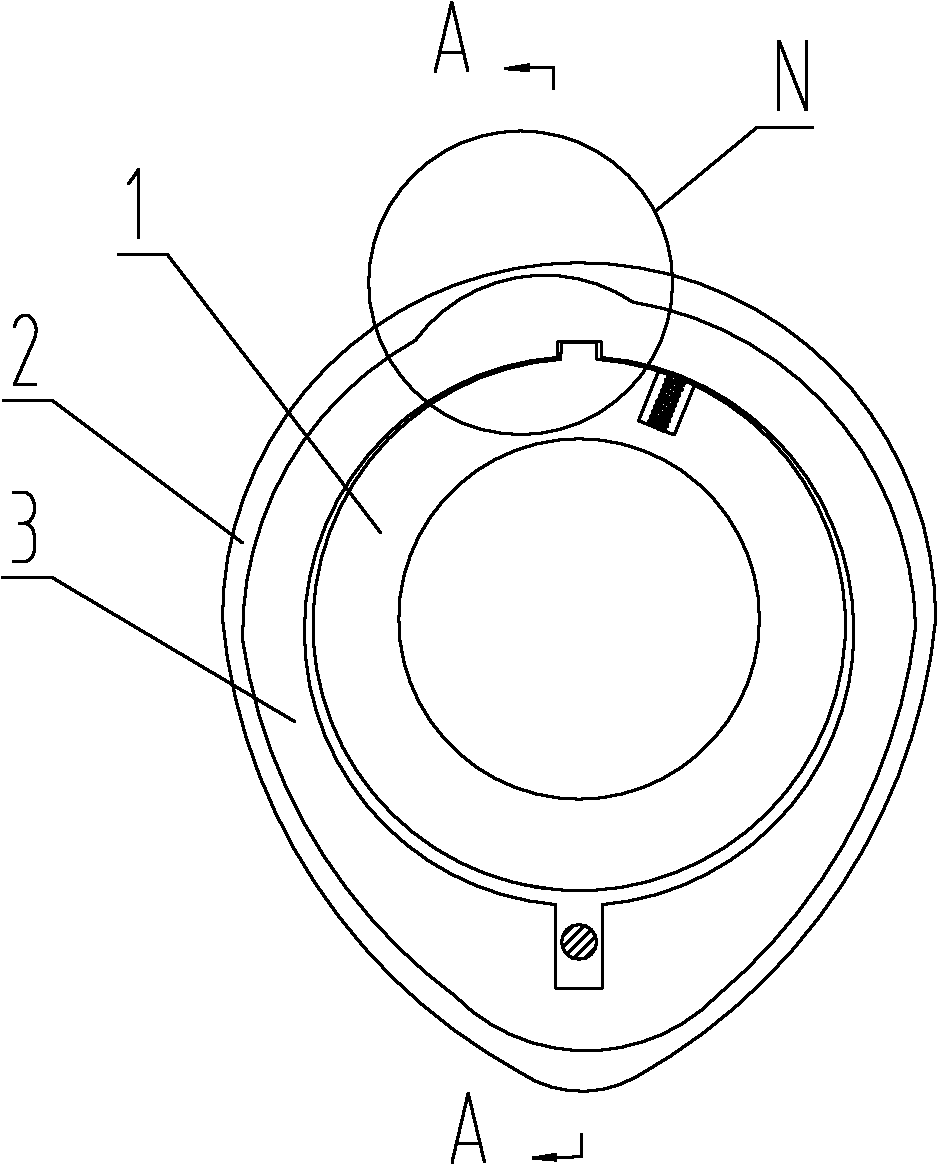

[0020] see Figure 1 to Figure 7 , a single camshaft type engine decompression mechanism under the motorcycle, including a camshaft, the camshaft includes a cam 2 and a journal 1 extending axially along one side of the cam, the journal 1 and the cam 2 are integrally formed, and the camshaft An eccentric slider 3 is movably sleeved on the neck 1. The shaft hole diameter of the eccentric slider 3 is larger than the outer diameter of the journal 1. The outer contour shape of the eccentric slider 3 is similar to that of the cam 2, and the eccentric slider The perimeter of the outer edge of the block 3 is smaller than the perimeter of the outer edge of the cam 2 . The outer edge surface of the eccentric slider 3 is provided with a flange 3a, the flange 3a of the eccentric slider is adjacent to the near-stop end of the cam 2, and the center of gravity of the eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com