Pressure reducing mechanism

A technology of decompression mechanism and decompression pin, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems such as difficulty in assembling the decompression structure, and achieve the effect of simple structure, meeting the needs of use, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

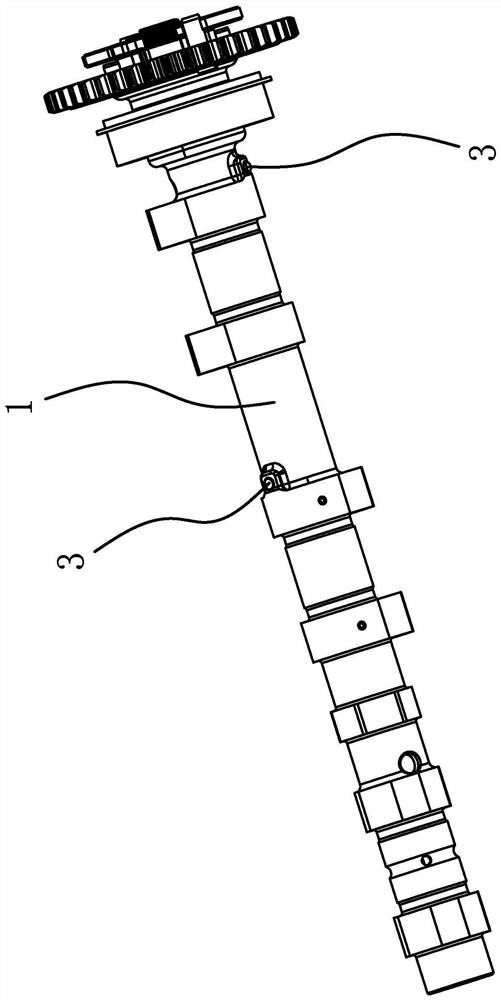

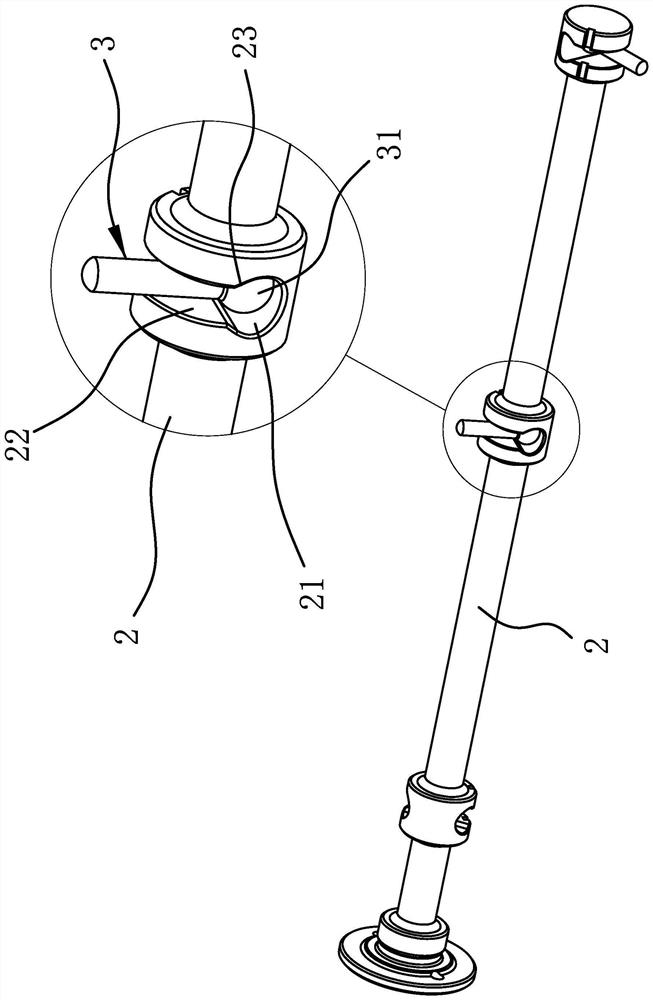

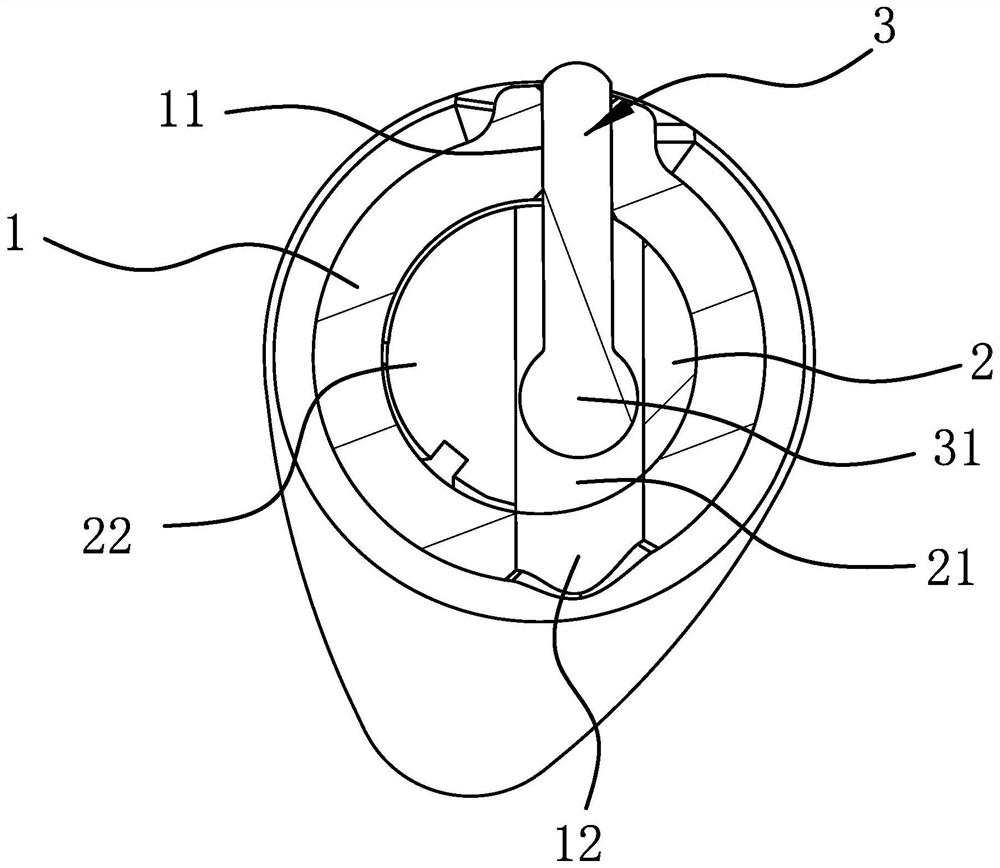

[0023] Such as figure 1 and figure 2 As shown, the decompression mechanism includes a hollow camshaft 1, a decompression shaft 2 coaxially penetrated in the camshaft 1, and a round bar-shaped decompression pin 3 arranged perpendicular to the axis of the decompression shaft 2. The opposite sides of the camshaft 1 are respectively provided with a pressure reducing hole 11 and a through hole 12 , and the outer end of the pressure reducing pin 3 is penetrated in the pressure reducing hole 11 and can protrude from the outer surface of the camshaft 1 .

[0024] Wherein, the decompression shaft 2 has a cylindrical installation part corresponding to the position of the decompression hole 11, the installation part is coaxially ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com