Leveling system of laser leveling device and adjusting method thereof

A debugging method and technology of a leveling instrument, applied in the field of leveling systems, can solve problems such as position changes, deviations, and weakened elastic force of the blister tube 18B, and achieve the effects of simple debugging methods, avoiding positioning deviations, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

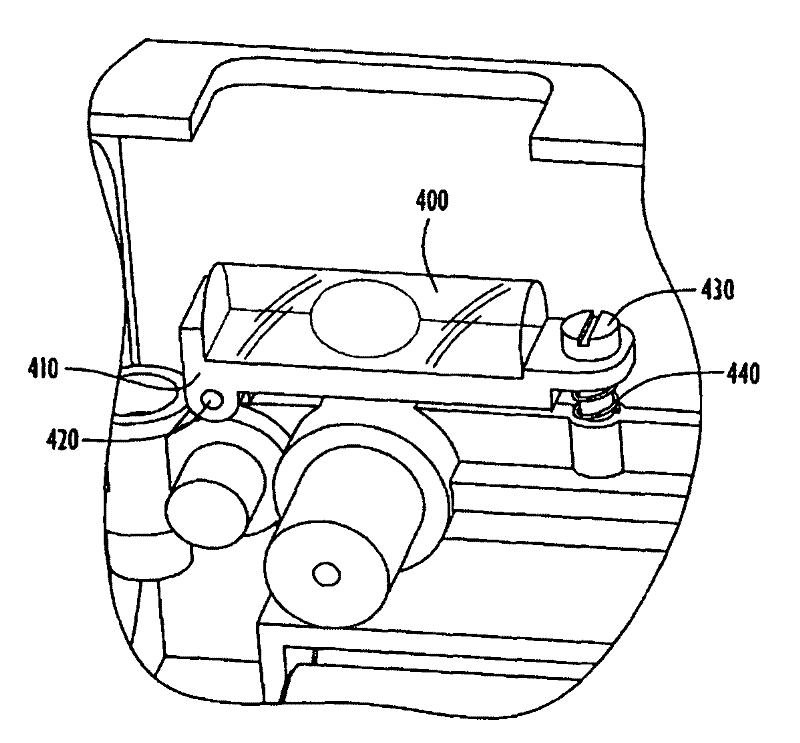

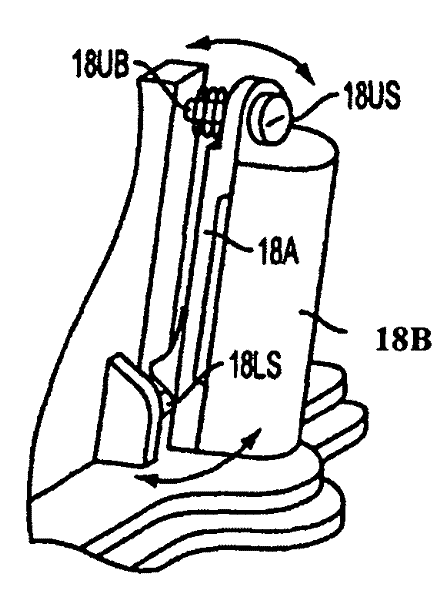

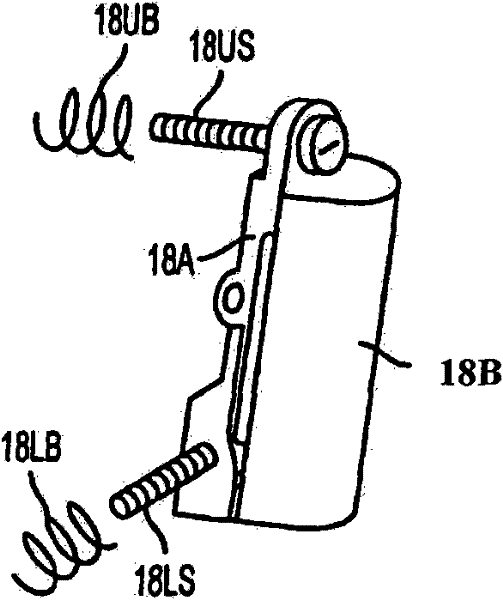

[0049] Embodiment 1 of the leveling system of the laser leveling instrument of the present invention includes a vertical installation and debugging part, and the vertical installation and debugging part will be described in detail below:

[0050] Such as Figure 4 , Figure 5 as shown, Figure 4 It is a schematic diagram of the three-dimensional structure of Embodiment 1 of the leveling system of the laser leveling instrument of the present invention; Figure 5 for Figure 4 The front view along the X direction of the leveling system of the laser leveler shown in . The leveling system 10 of the laser leveling instrument of the present invention includes a rotating part 20, a main body 12, a vertical sensor part 15 and a bubble tube 15B. The rotating part 20 has a laser beam exit hole 30 along the axis of the rotating part 20 . The light exit hole 30 is used to emit a positioning laser beam.

[0051] The main body 12 is provided with a frame 15H having two side walls para...

Embodiment 2

[0071] Such as Figure 9 , Figure 10 , Figure 11 and Figure 12 as shown, Figure 9 It is the front view of Embodiment 2 of the leveling system of the laser leveling instrument of the present invention; Figure 10 for Figure 9 Enlarged view of part E in middle; Figure 11 for Figure 9 The enlarged and exploded view of part E in the middle; Figure 12 for Figure 9 C-C sectional view of part E in middle. The difference between the second embodiment and the first embodiment is only that the connection method between the adjustment seat 15T′ and the main body 12 is different. In the second embodiment, the upper end of the back plate 150 of the adjustment seat 15T' is connected to the fixed plate 12P' through a cylindrical pin 21. The axis of the cylindrical pin 21 is perpendicular to the axis of the bottom wall adjustment screw 18, that is, parallel to the Y axis direction. The specific structure is: the cylindrical pin 21 is arranged on the upper wall 152T' of the...

Embodiment 3

[0086] Such as Figure 13 , Figure 14 as shown, Figure 13 It is a three-dimensional structural schematic diagram of Embodiment 3 of the leveling system of the laser leveling instrument of the present invention; Figure 14 for Figure 13 The leveling system of the laser leveler shown in is viewed along the X direction. In addition to the vertical sensor part 15 in the first or second embodiment, the present invention also includes a horizontal installation and debugging part, which includes the first sensor part 14 and the second sensor part 13 .

[0087] The first sensor part 14 includes a first blister tube 14B, a first frame 14H, a photocell circuit board 14L and a light-emitting diode 14D; the second sensor part 13 includes a second blister tube 13B, a second frame 13H, a photocell circuit board and a light-emitting diode, And the structures of the second sensor part 13 and the second sensor part 14 are completely the same. Both the second frame 13H and the first fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com