Differential-pressure method gas permeameter with energy utilization monitoring capability and environment detecting capability

A technology of gas penetration and detection capabilities, applied in the direction of permeability/surface area analysis, instruments, measuring devices, etc., can solve problems such as increased test volume, inaccurate acquisition and recording of environmental conditions, huge review workload, etc., to improve system safety Performance and stability, break through the limit of stand-alone storage, and good scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

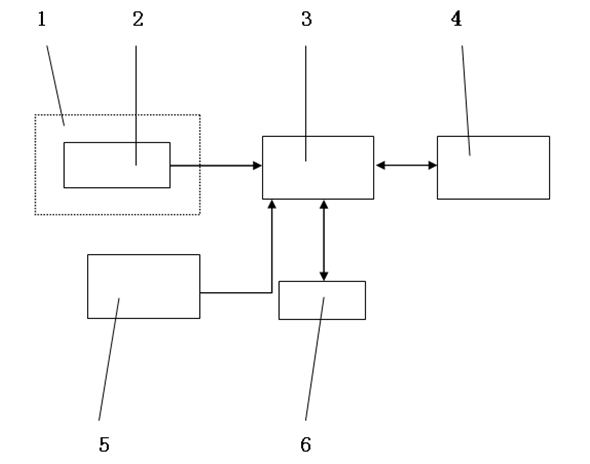

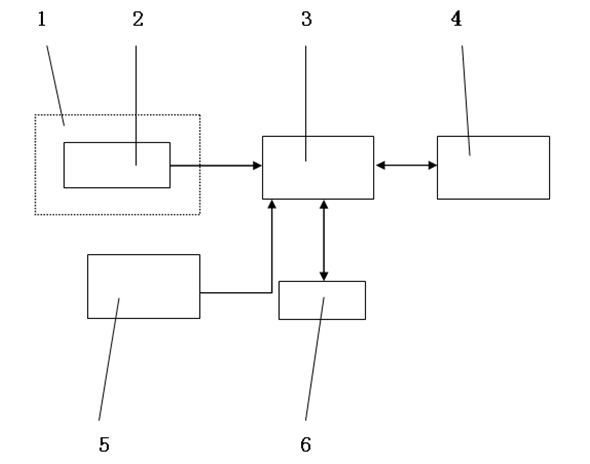

[0038] figure 1 Among them, the differential pressure gas permeation instrument of the present invention includes five parts: a processing unit 3 , a differential pressure gas permeation testing unit 4 , a storage unit 6 , an energy monitoring device 2 , and an environmental detection unit 5 . The processing unit 3 communicates bidirectionally with the differential pressure gas permeation testing unit 4 and the storage unit 6 ; the output of the energy monitoring device 2 and the output of the environment detection unit 5 are connected to the input of the processing unit 3 . The energy monitoring device 2 is installed in the power supply module 1 of the differential pressure gas permeation instrument, monitors the electric energy usage of the differential pressure gas permeation instrument, and sends the energy consumption data to the processing unit 3, and the energy monitoring device 2 is a power supply At least one of a current sensor and a supply voltage sensor or a smart ...

Embodiment 2

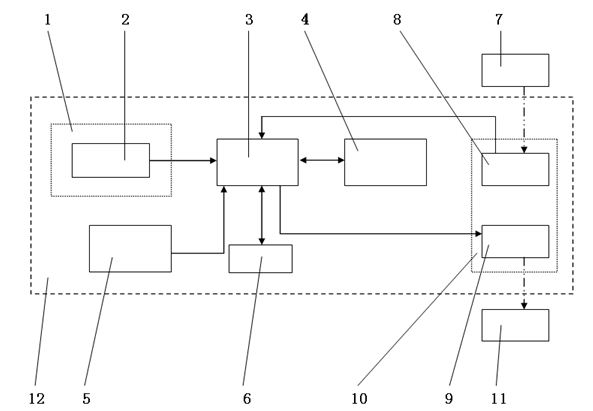

[0040] figure 2 Among them, the differential pressure gas permeation instrument 12 of the present invention includes six parts: a processing unit 3, a differential pressure gas permeation testing unit 4, a storage unit 6, an energy monitoring device 2, an environmental detection unit 5, and a communication unit 10. The collection of information and the data exchange between the differential pressure gas permeation meter 12 and external equipment also require the cooperation of the tag collection device 7 and the information server 11 . The processing unit 3 communicates bidirectionally with the differential pressure gas permeation testing unit 4 , the storage unit 6 , and the communication unit 10 ; the output of the energy monitoring device 2 and the output of the environmental detection unit 5 are connected to the input of the processing unit 3 .

[0041] The differential pressure method gas permeation instrument 12 is connected to the label collecting device 7 and the info...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com