Boring-milling machine

A boring and milling machine and boring bar technology, applied in the field of boring and milling machines, can solve the problems of small processing range, small telescopic range and high equipment cost of a single boring and milling machine, and achieve the effect of large processing range, large telescopic range and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

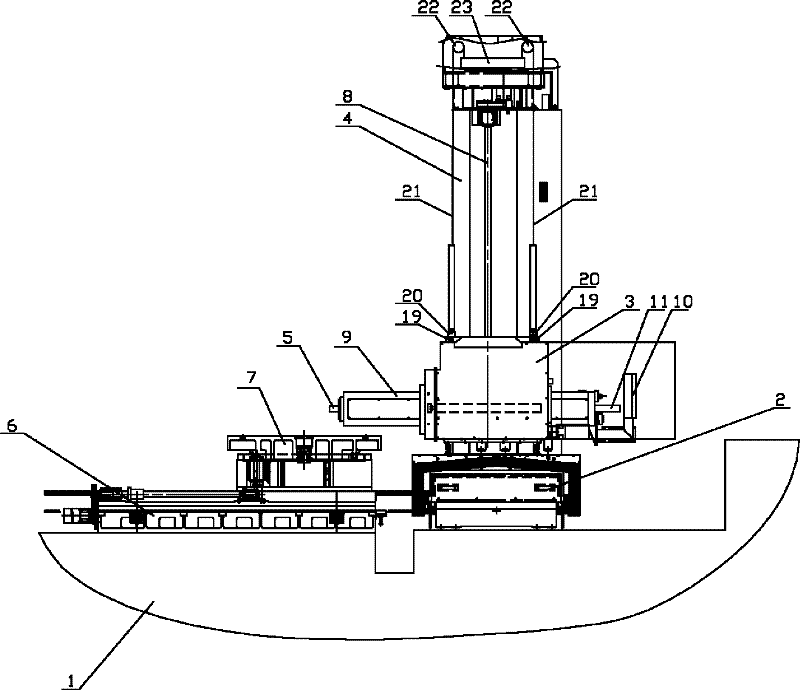

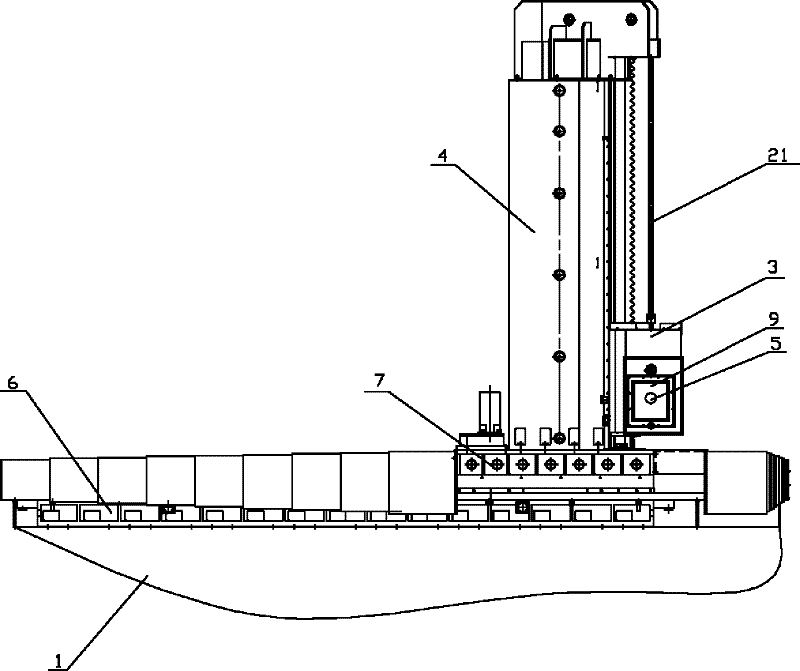

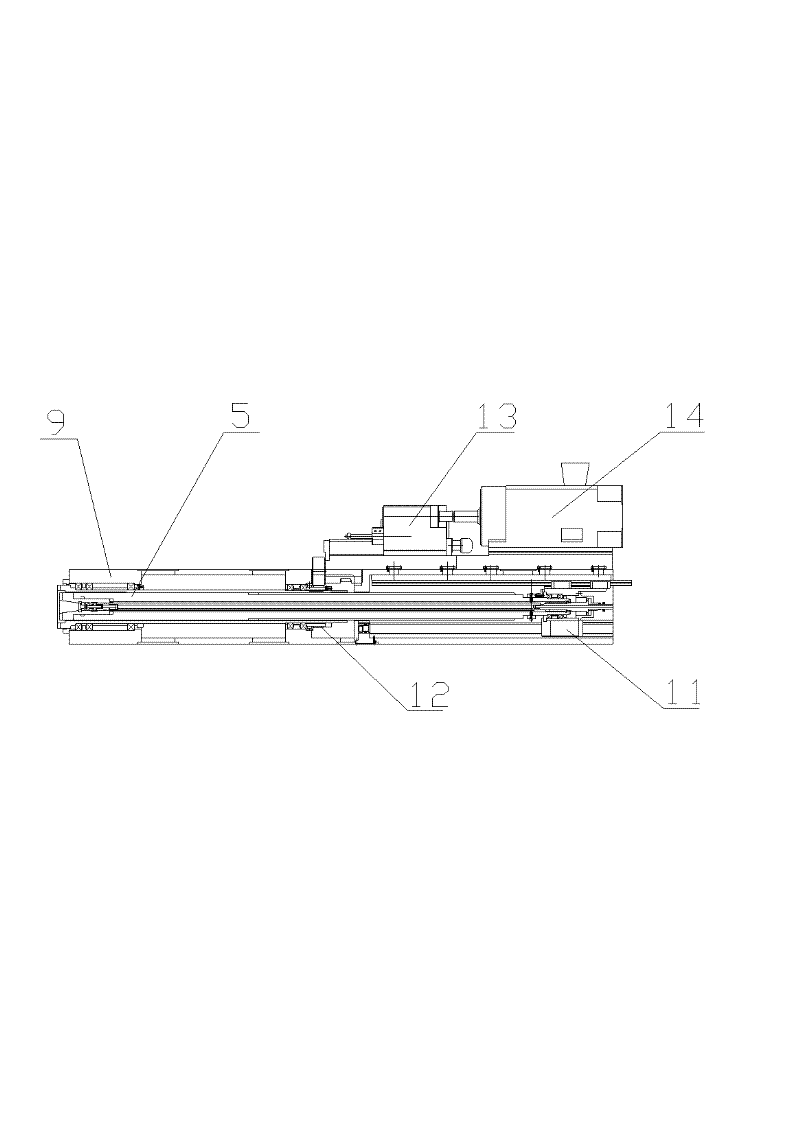

[0015] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , which includes a base 1, a workbench, a sliding seat 2, a spindle box 3, a column 4, and a boring bar 5. The workbench and the slide seat 2 are supported on the base 1. The workbench includes a workpiece moving workbench 6 and a workpiece rotary workbench 7. The column 4 is supported on the sliding seat 2, the workpiece rotary table 7 is supported on the workpiece moving table 6, the spindle box 3 is close to the side connecting the column 1, the top of the column 1 is connected to the spindle box 3 through the ball screw 8, and the inside of the spindle box 3 A ram 9 is installed, and a boring bar 5 is installed inside the ram 9. The ram 9 and the boring bar 5 face the workbench. In the sliding guide rail, a driving handle 10 is installed at the rear of the ram 9, and a driving rod 11 is installed at the rear of the boring bar 5. The end surface of the middle and rear part of the boring bar 5 has a conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com