Method of inspecting polarizing film

A technology of polarizing film and inspection method, applied in the direction of material analysis, measuring device, instrument, etc. by optical means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

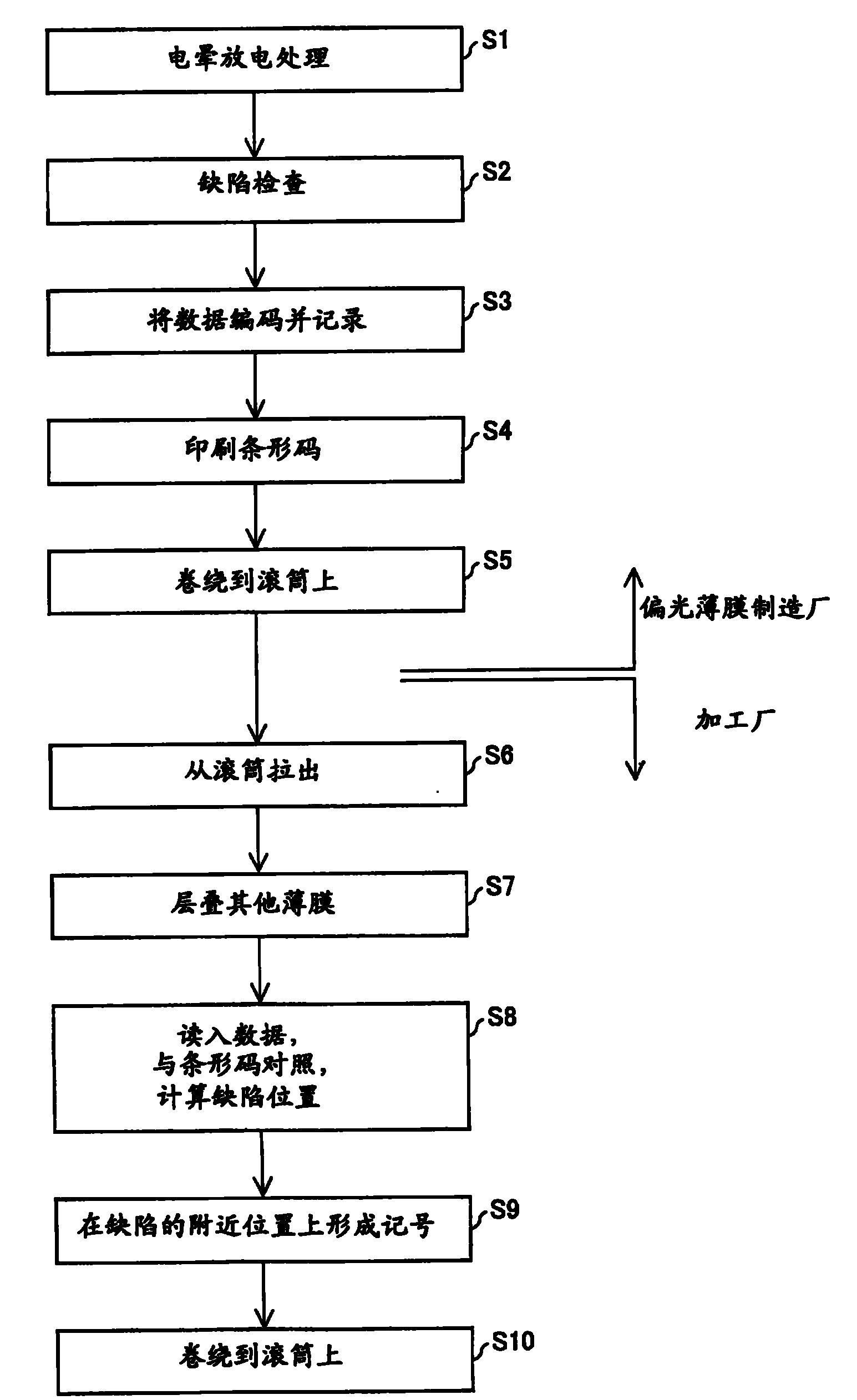

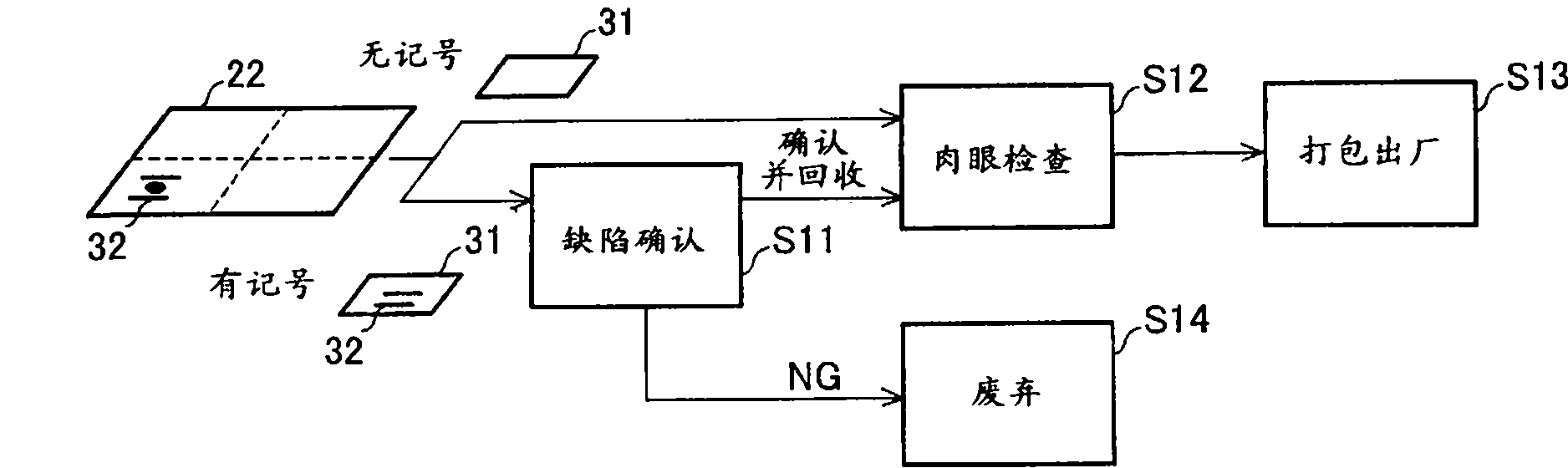

[0036] The following combination figure 1 One embodiment of the polarizing film inspection method of the present invention will be briefly described.

[0037] First, a corona discharge treatment is performed on the widthwise end surface of a raw polarizing film (a polarizing film that is formed into a long strip and can be cut to obtain a plurality of polarizing films having a size corresponding to the application) ( S1 ). As for the output of the corona discharge device used in the corona discharge treatment, it may be properly optimized. This step S1 is to make the surface of the end of the width direction of the polarizing film rough, so as to improve the adhesiveness of the printing ink and prevent the printed identification code from peeling off. However, this step can be omitted in the case of strong adhesiveness of the polarizing film. .

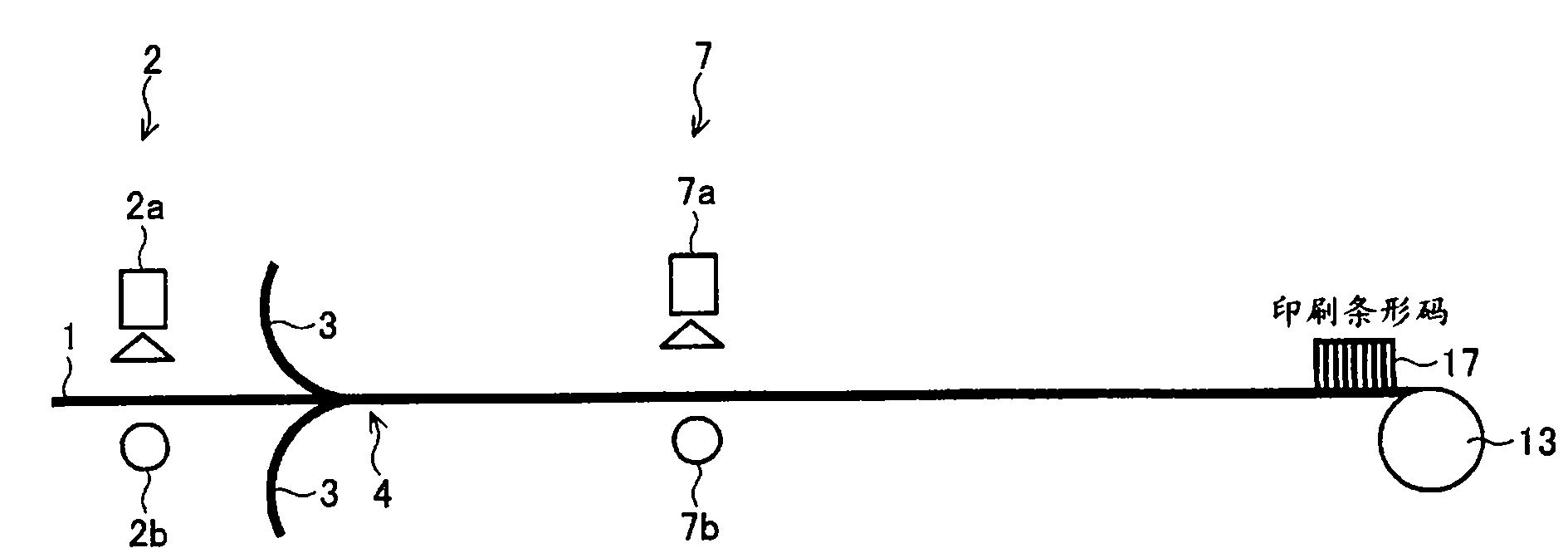

[0038] Then, for the original polarizing film, use an inspection device to inspect the surface or internal defects (scratch or for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com