Hoisting method of outer cover of main transformer

A technology of main transformer and hoisting method, which is applied in the field of substation maintenance and can solve problems such as uneven stress on the suspension rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

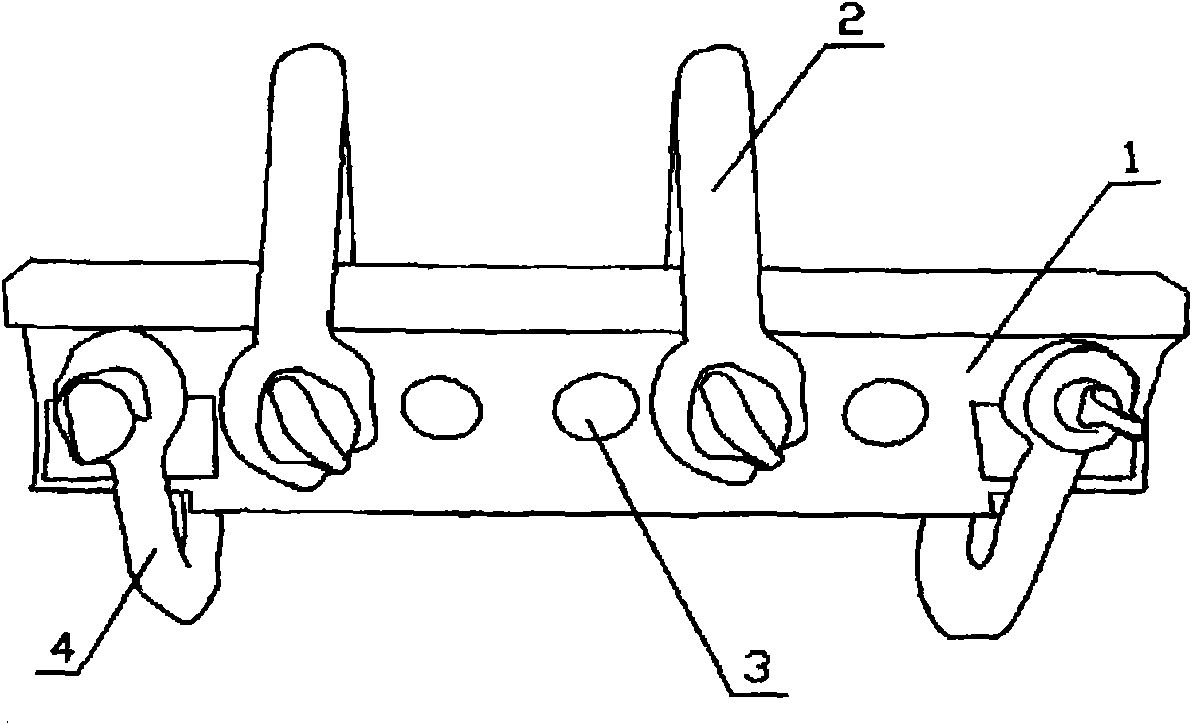

[0009] Such as figure 1 The dual-hook balanced sling used in the present invention includes a sling body 1, the sling body is connected to the sling through two hooks 2, the two sling body Two heavy object hooks 4 are arranged at the end of the spreader body, and a plurality of hook positioning holes 3 are arranged between the two heavy object hooks on the spreader body. A hook activity connection.

[0010] Using the double-hook balance sling can lift the main transformer cover as a whole without removing some accessories. The specific hoisting method is as follows: 1. Preparation before lifting: remove the connecting bolts of the cover, and the crane hook passes through the sling and the sling either The two lifting holes are connected, and then the main transformer cover is connected to the heavy object connecting hole of the sling through the lifting rope; 2. Trial lifting: Lift slowly to make each lifting rope bear the force, and then move from top to bottom in the four-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com