Stepped anti-subsidence leg of ocean platform

An offshore platform, stepped technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve problems such as hidden dangers of offshore platform production safety, large driving depth of friction piles, slow settlement of pile legs, etc. Improve installation efficiency and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

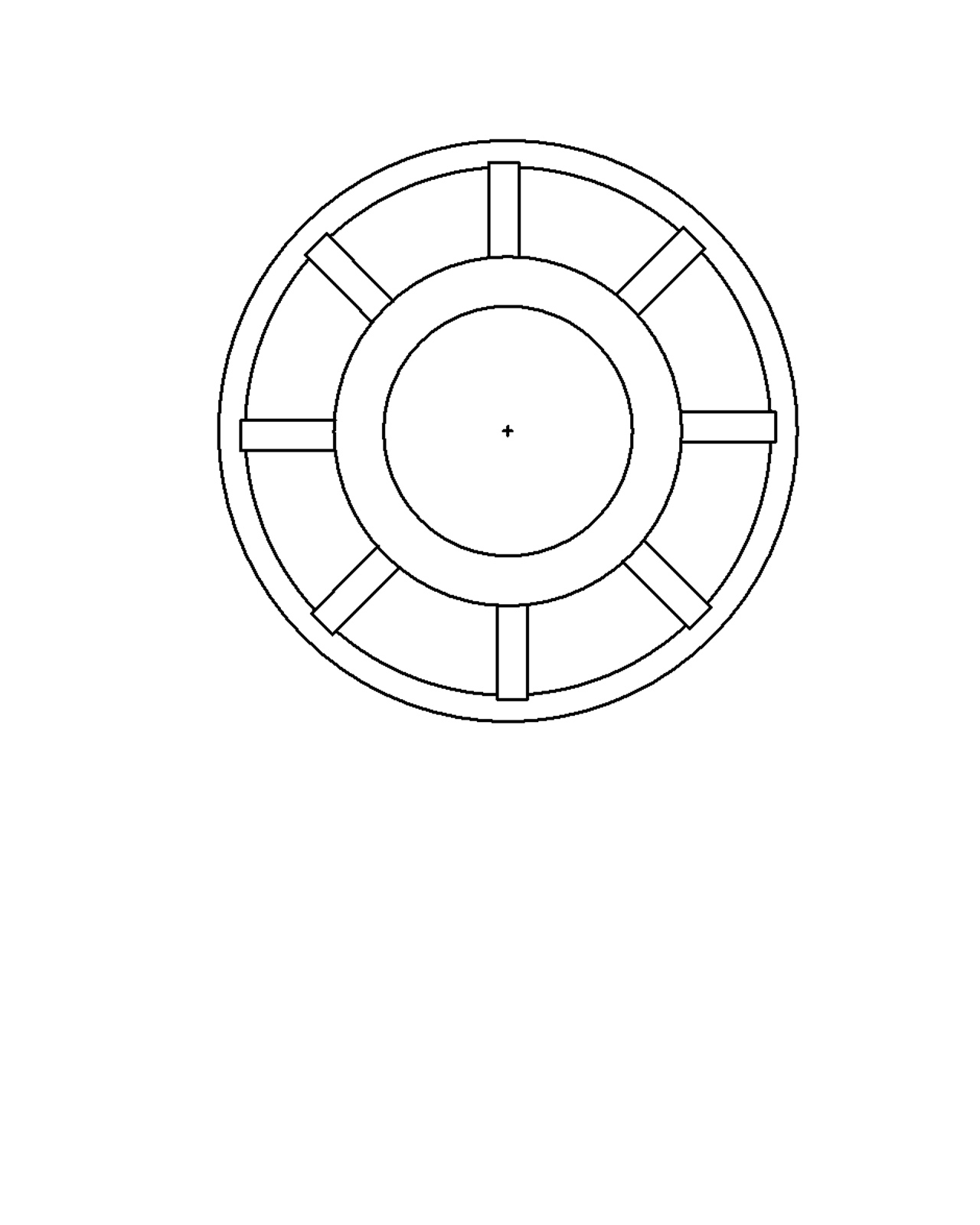

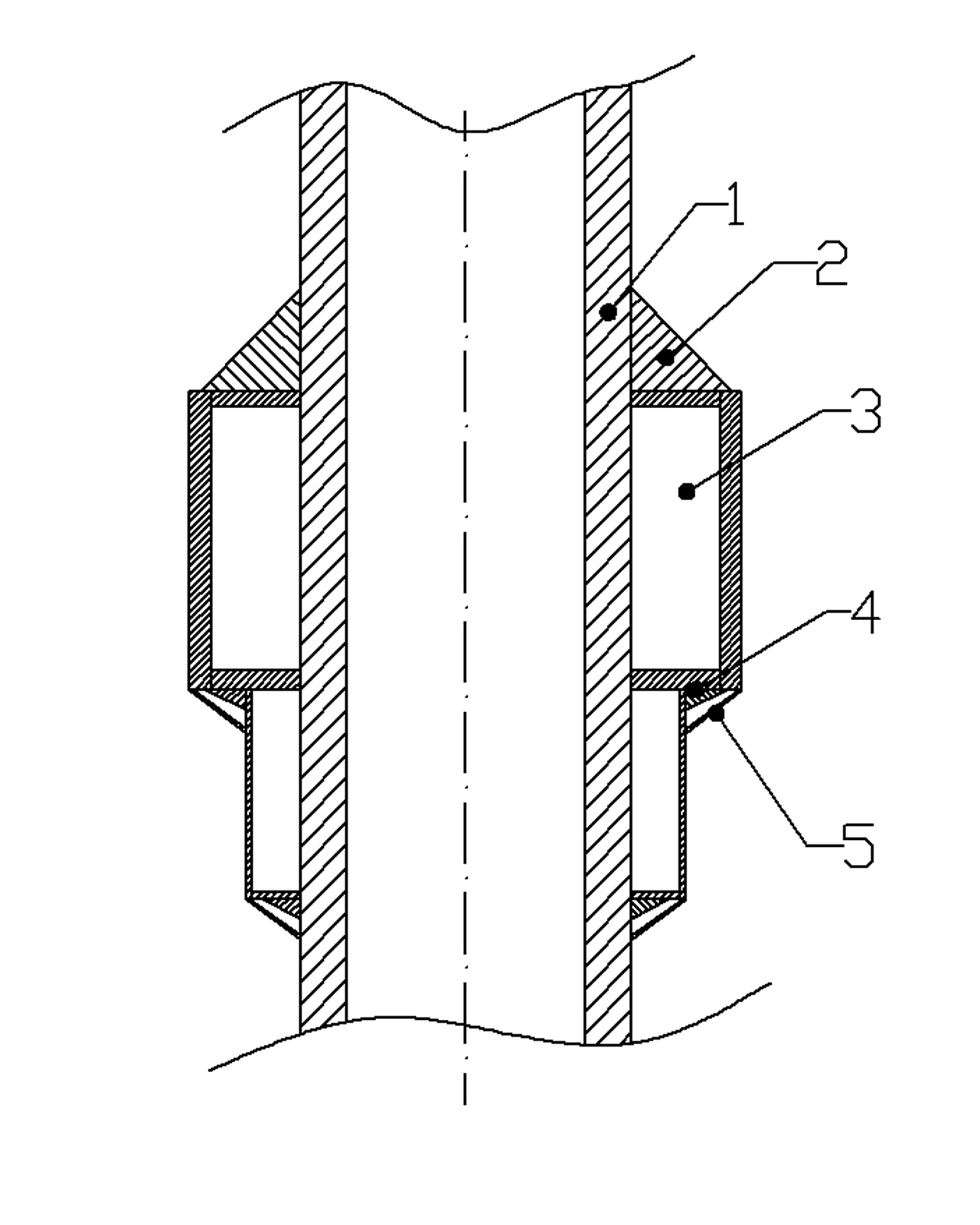

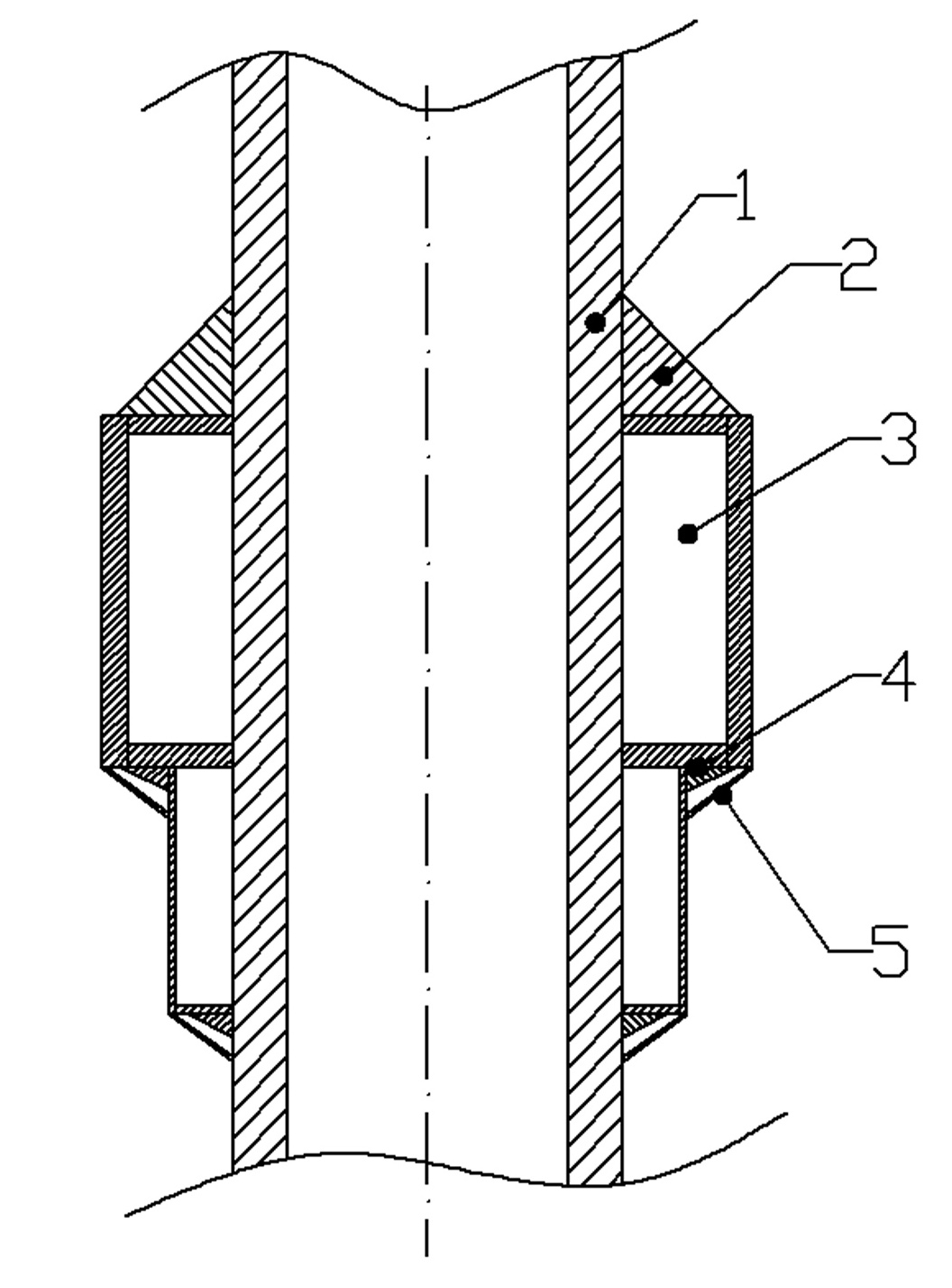

[0011] Such as Figure 1-2 As shown, the present invention includes pile leg 1, rib plate 2, step ring 3, transition section 4, and annular metal ring 5, and rib plate 2 is welded between pile leg 1 and step ring 3 to relieve stress concentration; step ring 3 It is formed by welding and stacking a plurality of steel pipes with different outer diameters, and a transition section 4 is welded at the connection of every two steel pipes, and the transition section 4 is covered with an inclined annular metal ring 5 .

[0012] The transition section 4 is composed of inclined steel rings and small ribs; there are 8 ribs 2, which are evenly distributed and welded between the pile leg 1 and the stepped ring 3; the angle between the annular metal ring 5 and the horizontal plane is 30°; the stepped ring 3 is a hollow body, and the pipe diameter becomes larger from bottom to top; the largest pipe diameter of the stepped ring 3 is 2.5 times the pipe diameter of the pile leg 1; Depth; Annul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com