Method for preparing super absorbent resin containing composite plant growth regulator and dehydrated Murashige and Skoog's (MS) culture medium

A technology of plant growth regulator and superabsorbent resin, which is applied in the field of preparation of new superabsorbent resin, can solve the problems of restricting the application of MS medium, fast water volatilization, etc., to reduce watering times, improve absorption efficiency, and eliminate three wastes The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

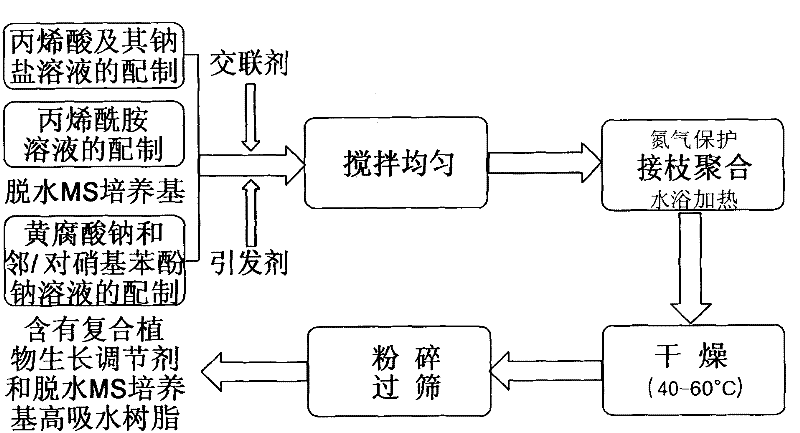

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Dissolve 6.0g sodium hydroxide with 19ml deionized water, under ice-water bath cooling and stirring, neutralize 27g (25.6ml) acrylic acid; Dissolve 0.1g sodium fulvic acid, 0.05g o-nitrate with 25ml deionized water Sodium phenoxide and 0.05g sodium p-nitrophenolate, then add neutralized acrylic acid and its sodium salt solution, 10g dehydrated MS medium, 100mg potassium persulfate, 30mg N, N'-methylenebisacrylamide, at room temperature Stir for 1.0h, then heat slowly under the protection of nitrogen, make it react at 60-80°C for 1h, continue to heat up, keep warm in a boiling water bath for 1.5h, stop nitrogen, cool to room temperature, take out the product, dry, Pulverize and sieve to obtain superabsorbent resin containing compound plant growth regulator and dehydrated MS medium. The water absorption ratio of the product obtained in this example is 570 times.

Embodiment 2

[0017] Embodiment 2: experimental condition is the same as embodiment 1, and difference is to dissolve 0.01g sodium fulvic acid, 0.01g o-nitrophenolate sodium and 0.01g p-nitrophenolate sodium with 25ml deionized water, the water absorption of the product obtained in this embodiment The multiple is 590 times.

Embodiment 3

[0018] Embodiment 3: experimental condition is the same as embodiment 1, and difference is to dissolve 0.1g sodium fulvic acid, 0.1g o-nitrophenolate sodium and 0.1g p-nitrophenolate sodium with 25ml deionized water, the water absorption of the product obtained in this embodiment The multiple is 450 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com