Electric nail hammer

A nail hammer and electric technology, applied in nail tools, nail dispensers, packaging, etc., can solve the problems of easy hitting fingers, low work efficiency, low safety, etc., to increase convenience and universality, and save manpower , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

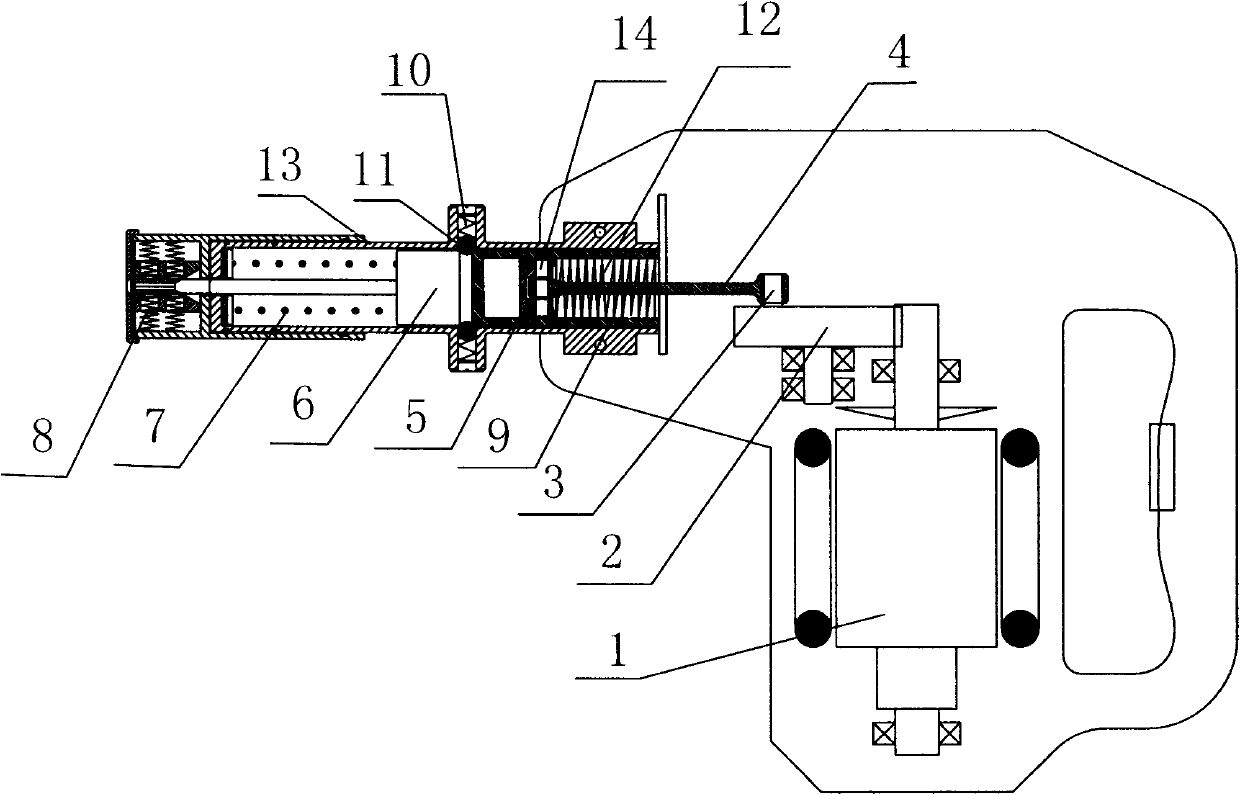

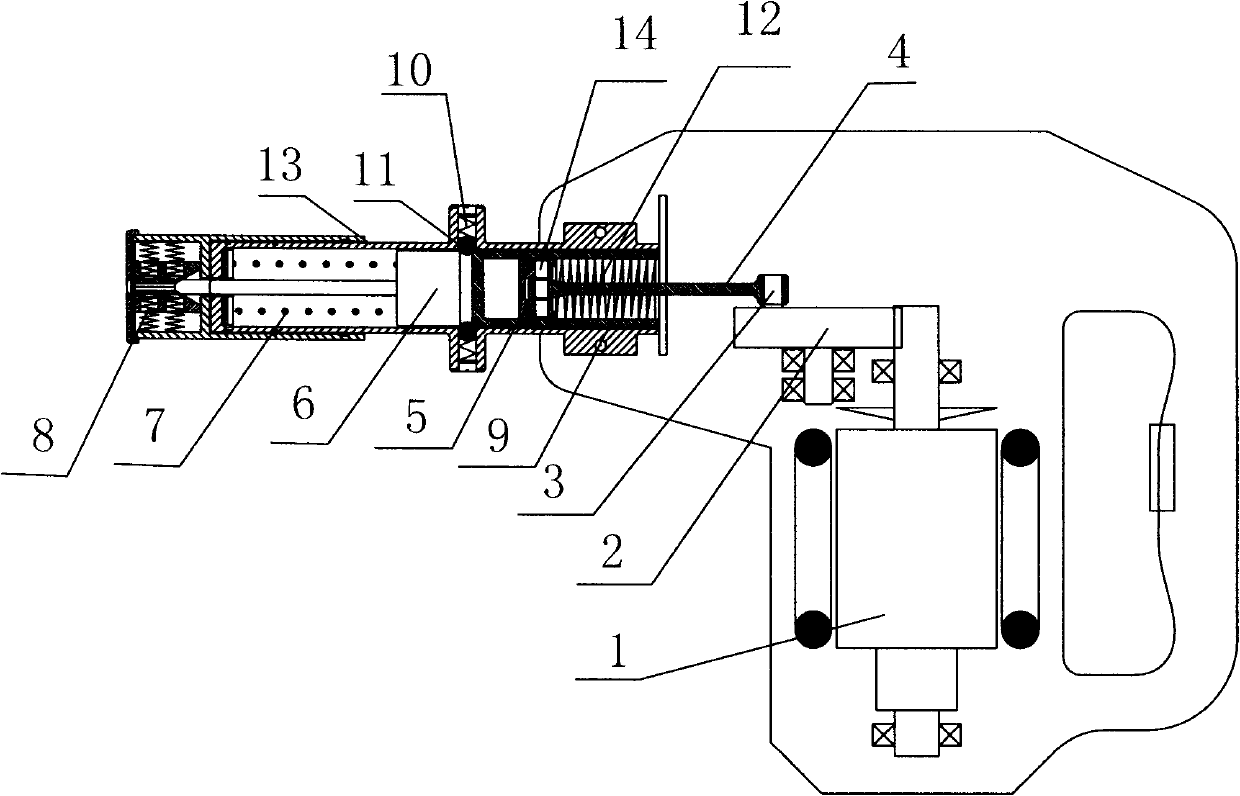

[0022] See attached figure 1 , an electric mace comprising

[0023] It includes a driving device for generating driving force. In this embodiment, the driving device is a motor 1 .

[0024] Transmission device, one end of the connecting rod 4 of the transmission device is rotatably connected with the drive pin 3 arranged on the end face of the driven gear 2 of the gear set and perpendicular to its end face; the other end is rotatably connected with the piston 5 through the piston pin 14 .

[0025] The guide sleeve device 13 is a hollow cylinder used to limit the movement path of the rear spring type pneumatic energy storage device.

[0026] The rear spring type pneumatic energy storage device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com