Cap unscrewing device

A technology of parts and studs, which is applied in the field of cap screwing device, can solve the problems of labor-saving, fixed size of capping device, and inability to adapt to the opening requirements of bottle caps of different sizes, etc., and achieve the effect of easy unscrewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

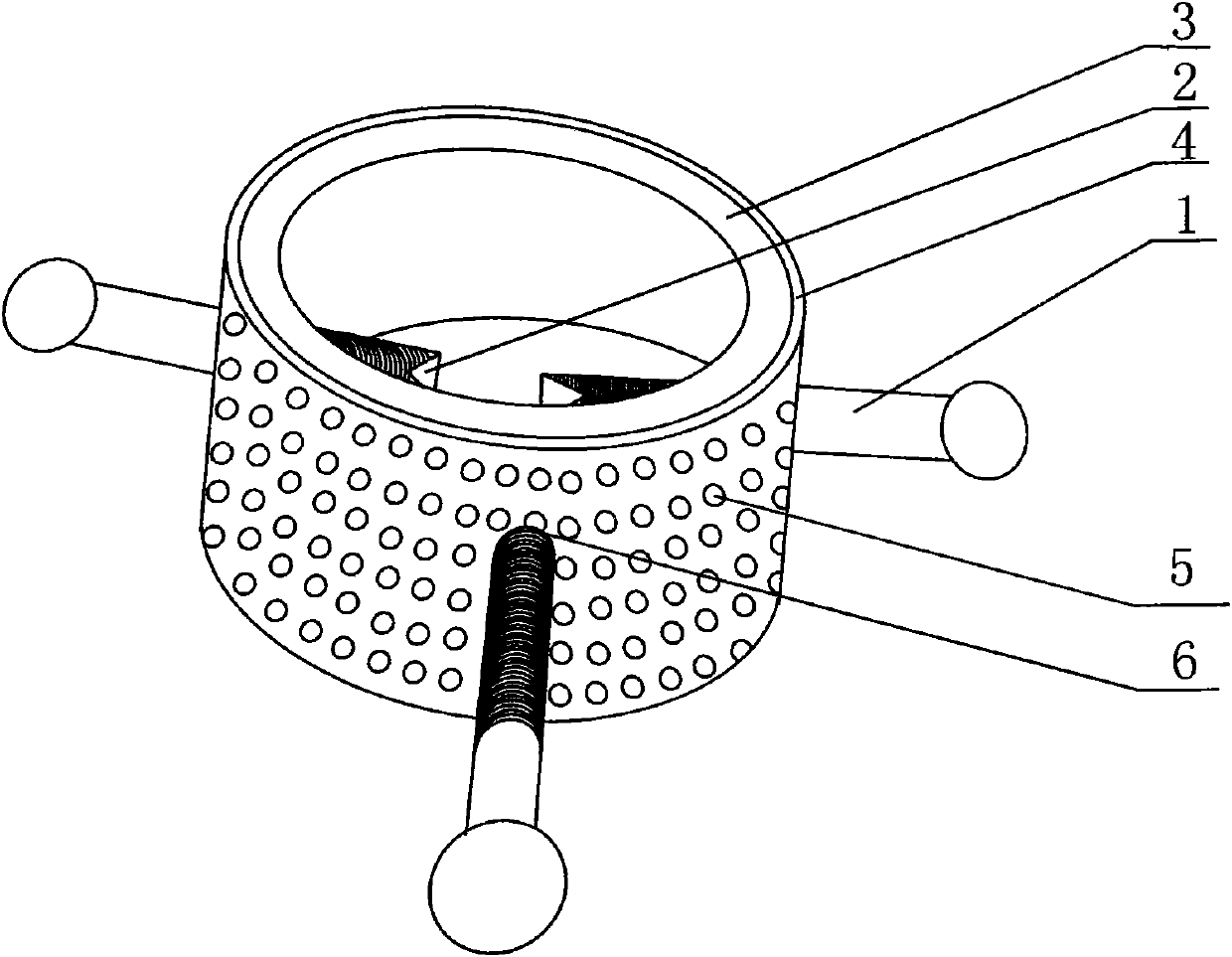

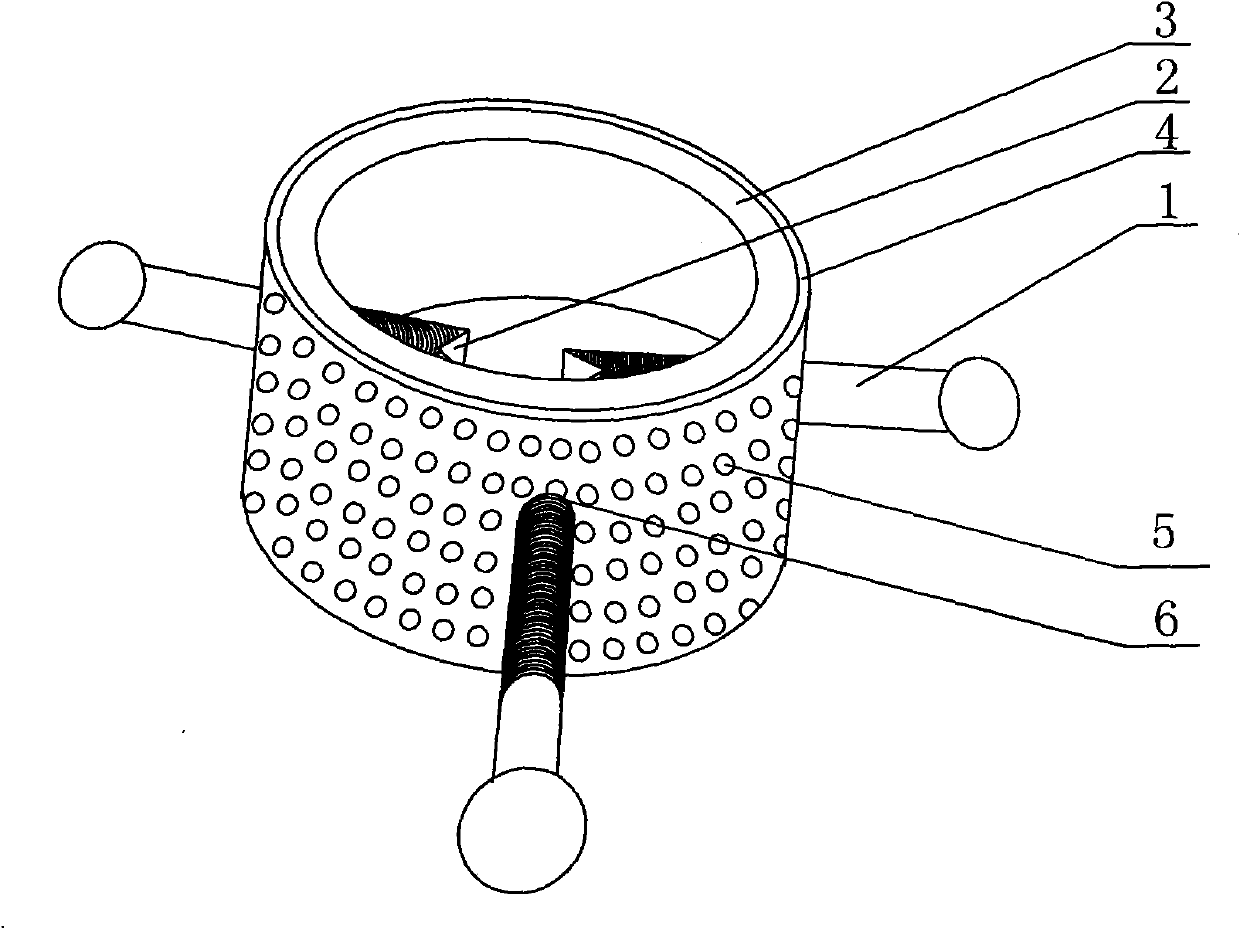

[0014] combine figure 1 , the hollow cylinder 3 is used as a rotating guide part, and three threaded holes 6 are evenly distributed along the circumference of the hollow cylinder 3, and the threaded holes 6 are respectively screwed with studs 1 to form adjustment parts; the three studs 1 are located inside the hollow cylinder 3 The top end constitutes the clamping part. Wherein, the length of one stud is longer than the other two studs, and the rotation of this stud facilitates the use of the relationship principle between force and torque to increase the torque when people unscrew the bottle cap. In order to better implement the present invention, the top end of the stud 1 positioned at the inner side of the hollow cylinder 3 is set as a V-shaped groove 2 parallel to the axis of the hollow cylinder, so that the contact points between the stud and the bottle cap as a clamping part increase , so as to increase the torque when people unscrew the bottle cap; similarly, a rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com