High-pressure safety valve disassembling tool

A disassembly tooling, high-pressure safety technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of unfavorable disassembly, affecting the accuracy of the yoke rod, low efficiency, etc., and achieve the effect of easy unscrewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

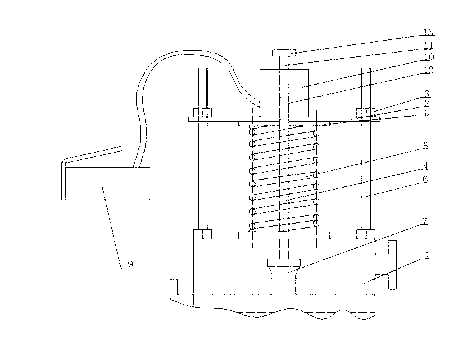

[0011] figure 1 The shown disassembly tooling for a high-pressure safety valve includes a valve 1, a pressure plate 2, a lock nut 3, a valve stem 4, a spring 5, a yoke rod 6, a valve core 7, a limiting boss 8, a hydraulic pump 9, and a hydraulic cylinder 10 , Sleeve coupling 11, central hole 12, shoulder structure 13.

[0012] figure 1 The high-pressure safety valve dismounting tool is set directly above the valve pressing device, and the pressing device includes a pressing plate 2, a lock nut 3, a valve stem 4, a spring 5 and two symmetrical and vertically arranged yoke rods 6, The spring 5 is mainly used to provide a certain pressure. One end of the spring 5 is pressed against the valve core 7, and the other end is pressed against the bottom surface of the pressure plate 2 through the limit boss 8. The two ends of the pressure plate 2 pass through the symmetrical and vertically arranged yoke rods 6, And put the lock nut 3 on the yoke rod 6, so as to provide a certain pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com