Medical bone cement directional automatic push injection device

A bone cement, automatic technology, applied in the field of medical devices, can solve the problems of limited length of the outlet tube, increased surgical risk, leakage of the vertebral body, etc., and achieves the effect of reducing workload, shortening operation time, and facilitating injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

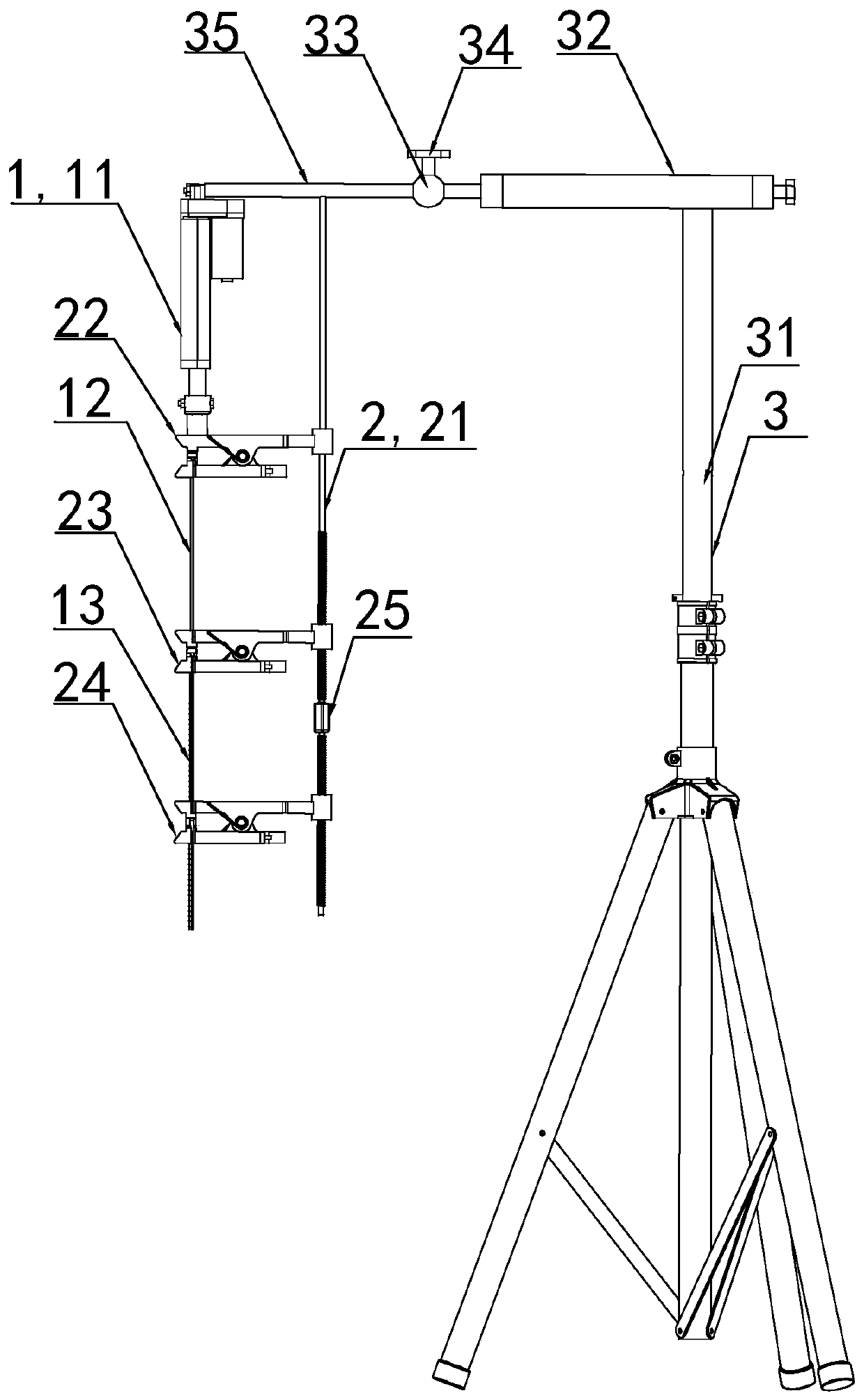

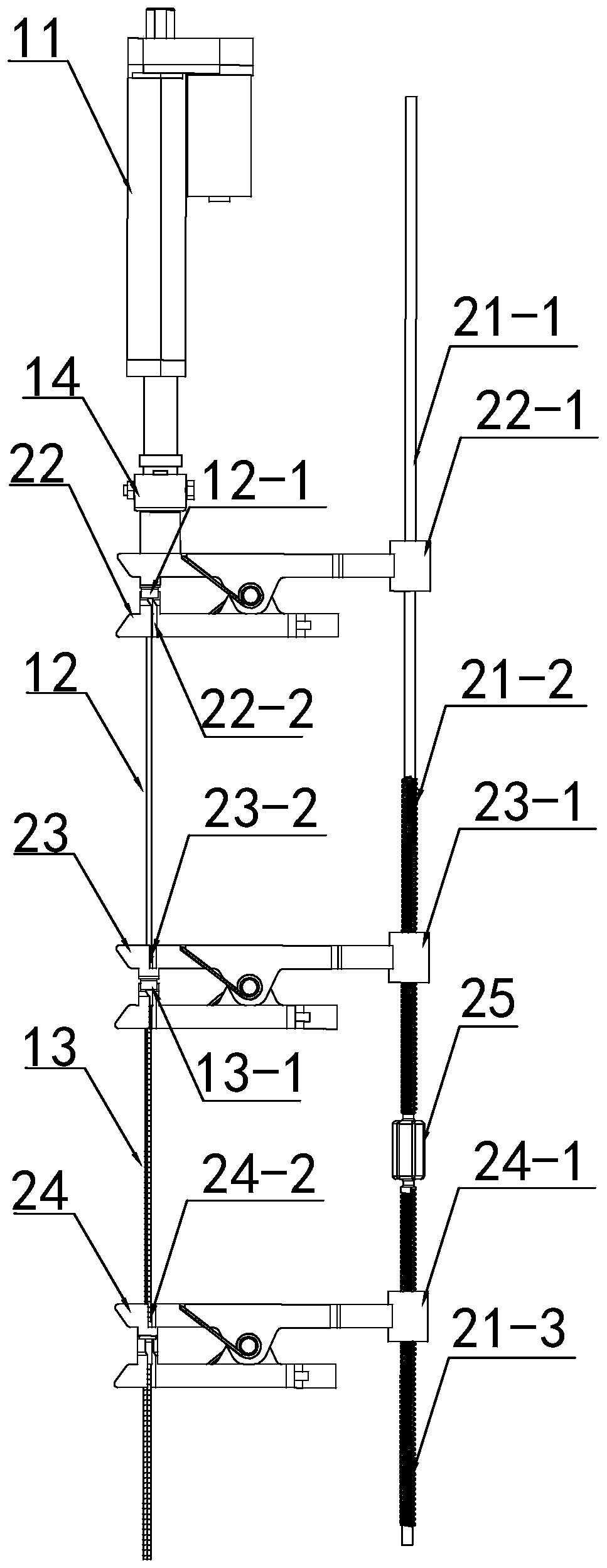

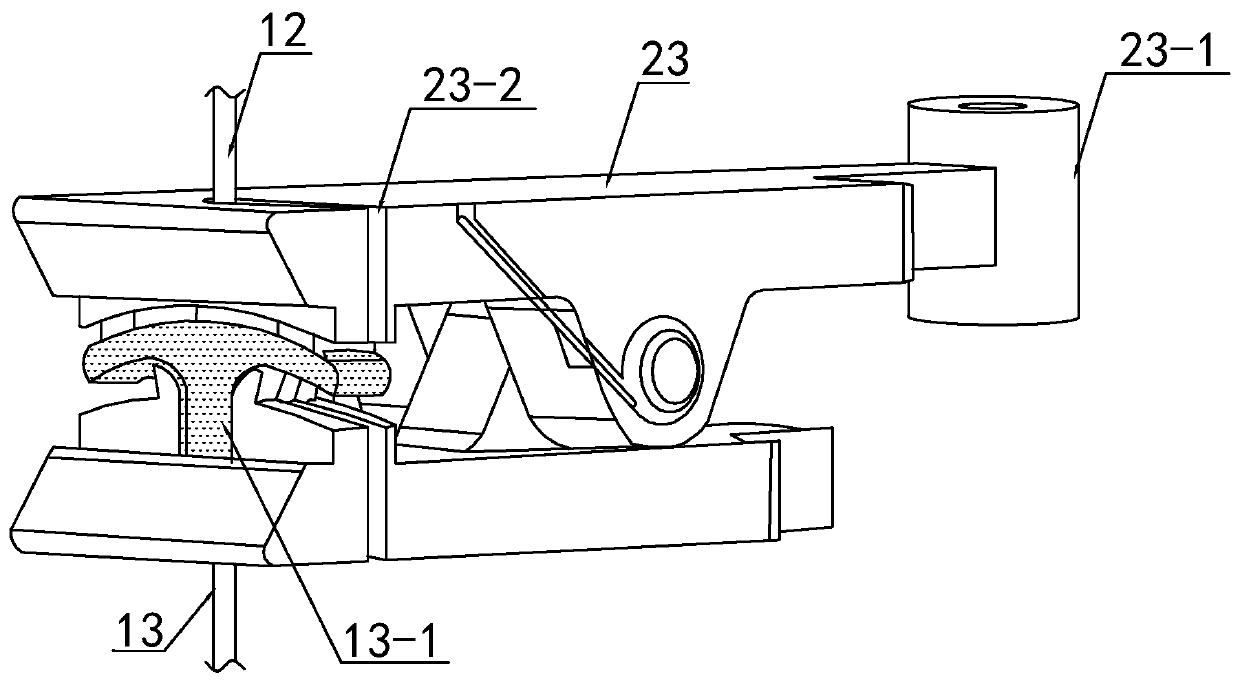

[0037] See Figure 1 to Figure 3, the medical bone cement directional automatic injection device of this embodiment includes a linear propulsion mechanism 1 , a guiding mechanism 2 and a bracket 3 . The linear propulsion mechanism 1 includes a linear motor 11 , a bone cement push rod 12 and a bone cement sleeve 13 arranged vertically from top to bottom. The bone cement push rod 12 extends into the bone cement casing 13, and the linear motor 11 is fixed on the bracket 3 by hanging from its top. The guide mechanism 2 includes a support shaft 21 and a first fixing clip 22 , a second fixing clip 23 and a third fixing clip 24 sleeved on the supporting shaft 21 from top to bottom. The supporting shaft 21 is fixed on the support 3 by its top hanging type, the first fixing clip 22 can slide up and down along the supporting shaft 21, and the second fixing clip 23 and the third fixing clip 24 are limited on the supporting shaft 21 up and down. The motor push rod of the linear motor 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com