Dynamic statistic sampling control method and device for on-line defect scanning

A defect scanning and dynamic statistics technology, applied in electrical program control, semiconductor/solid-state device manufacturing, program control in sequential/logic controllers, etc., can solve the problem of increased cost, particles attached to the wafer, unable to alert maintenance personnel, etc. problems, to avoid lengthening, avoid cost increases, and enhance defect monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

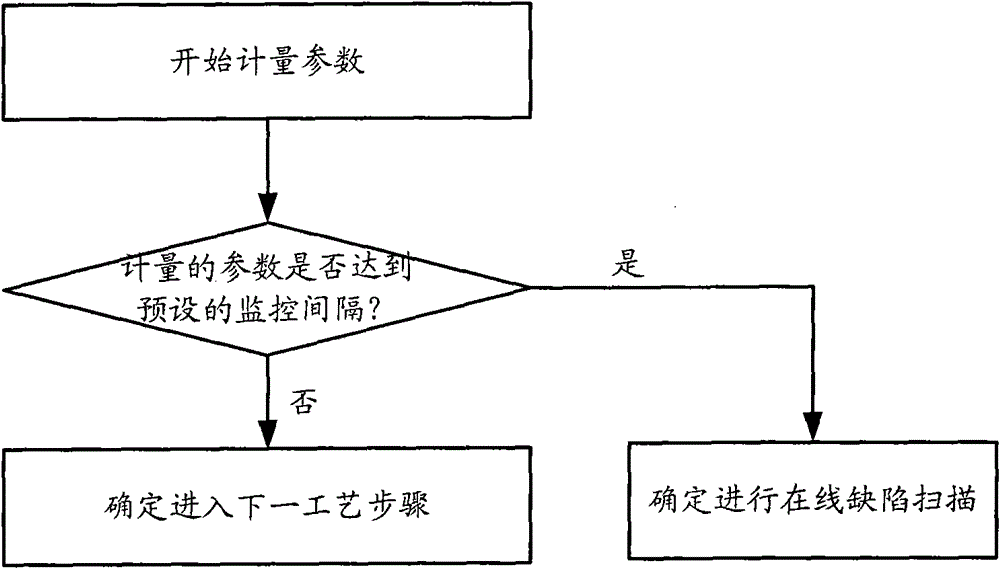

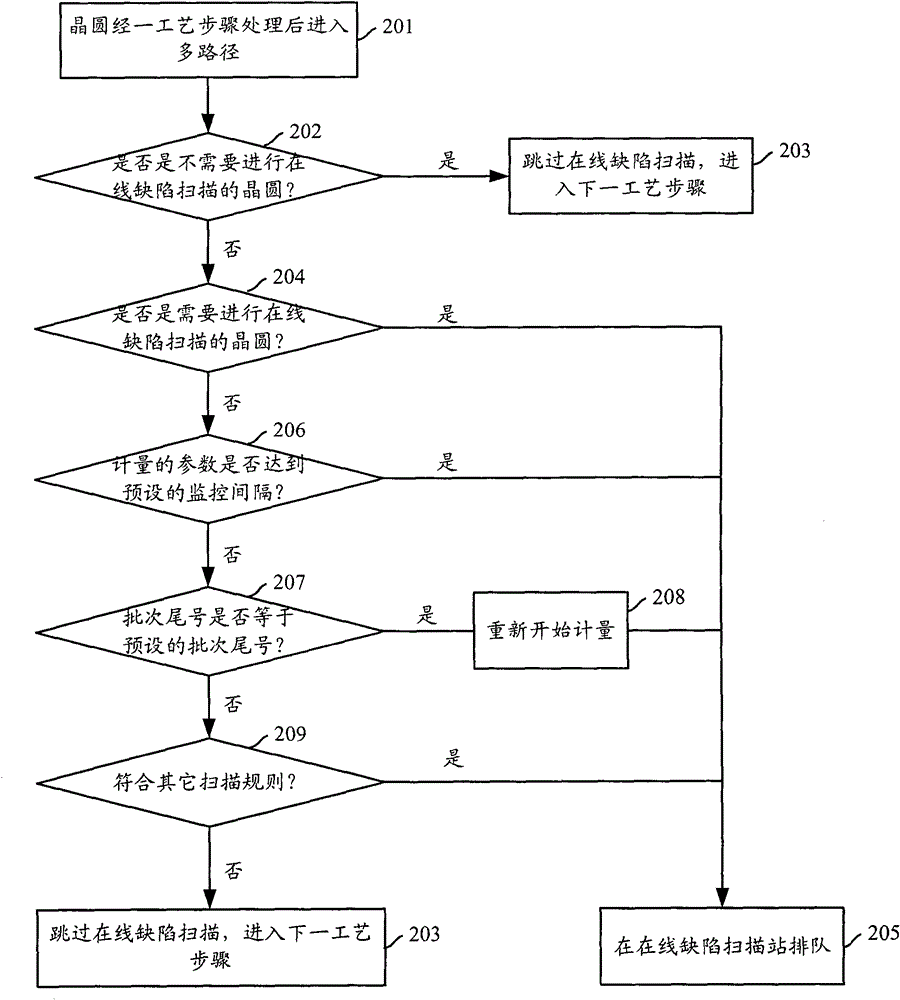

[0021] figure 1 It is a flow chart of the dynamic statistical sampling control method for online defect scanning of the present invention. see figure 1 The dynamic statistical sampling control method for online defect scanning provided by the present invention determines whether online defect scanning needs to be performed on wafers processed in process steps by judging whether the metering parameters have reached a preset monitoring interval. Specifically, if the metered parameters reach the preset monitoring interval, it is determined to perform online defect scanning on the wafer processed by the process step, otherwise it is determined to perform the next process step on the wafer processed by the process step, so that The problem of being unable to monitor wafer defects for a period of time and monitoring a large number of wafers for a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com