Valve for a microfluidic system

A technology of microfluidic system and volume change, applied in the field of microfluidic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

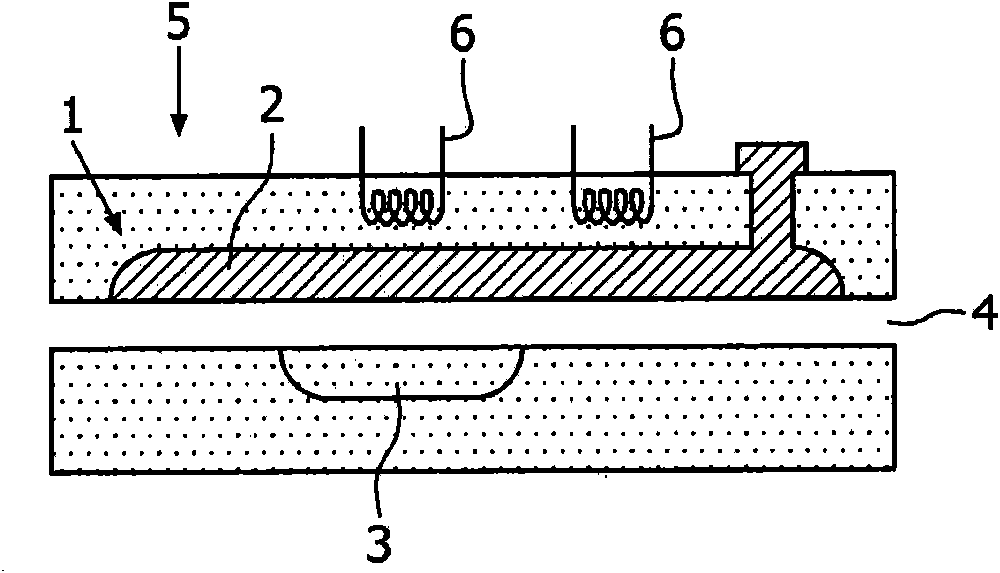

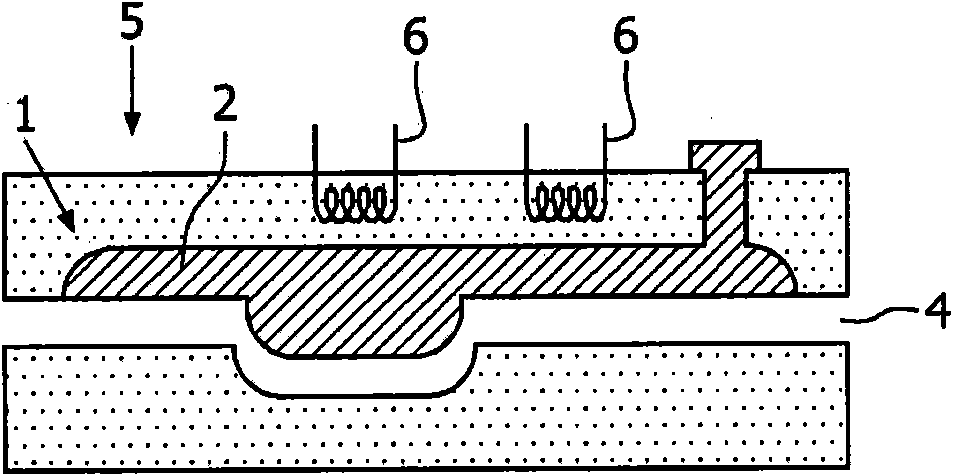

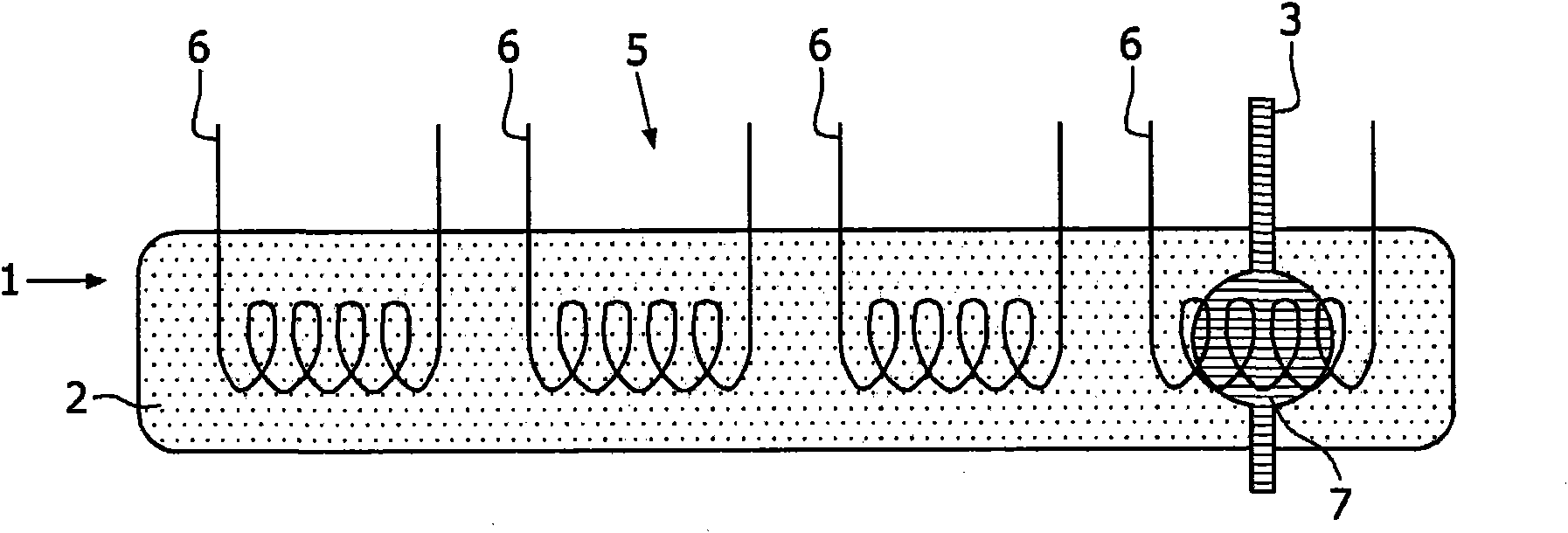

[0045] From Figures 1a and 1b, a valve according to a first preferred embodiment of the invention can be seen in a schematic side view. The valve comprises a medium container 1 containing an actuating medium 2 such as polyethylene glycol. With the help of an elastic membrane 4 made of PDMS and having a thickness between 100 μm and 300 μm, the actuating medium 2 in the medium container 1 is sealed against the chamber 3 to be closed and opened respectively by a valve.

[0046] From FIGS. 1 a and 1 b it can further be seen that a heater arrangement 5 comprising two heaters 6 is provided. The heater 6 in the heater arrangement 5 of the preferred embodiment shown here is designed as a thin-film heater element so that the valve can be controlled electronically. By activating these heaters 6, a phase transition from solid / crystalline to liquid / amorphous and thus a volume expansion can be achieved, resulting in closing of the channel 3 by heating the heaters 6 of the heater arrangeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com