Connector assembly

A technology of connectors and assemblies, applied in packaging, connecting tubes, medical containers, etc., which can solve the problems of medical workers who are accidentally punctured by needle points and transfer liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

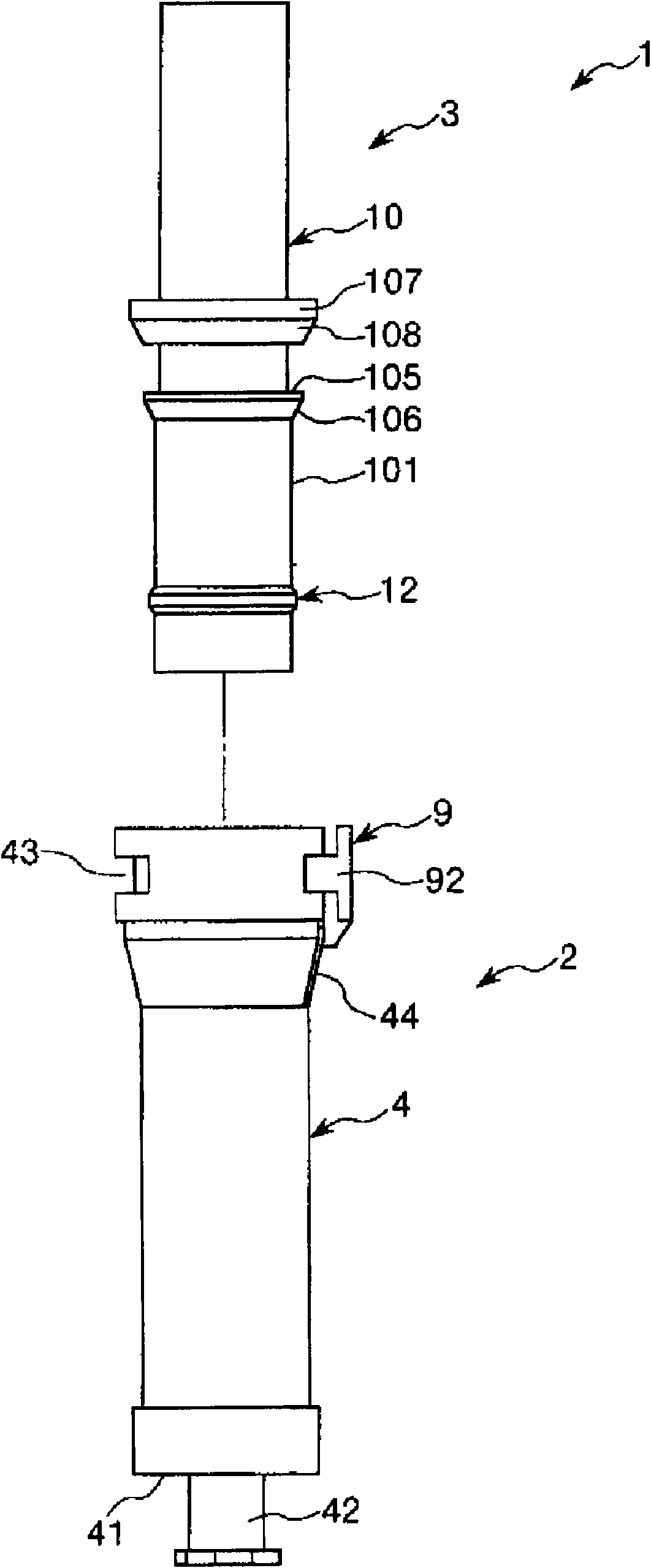

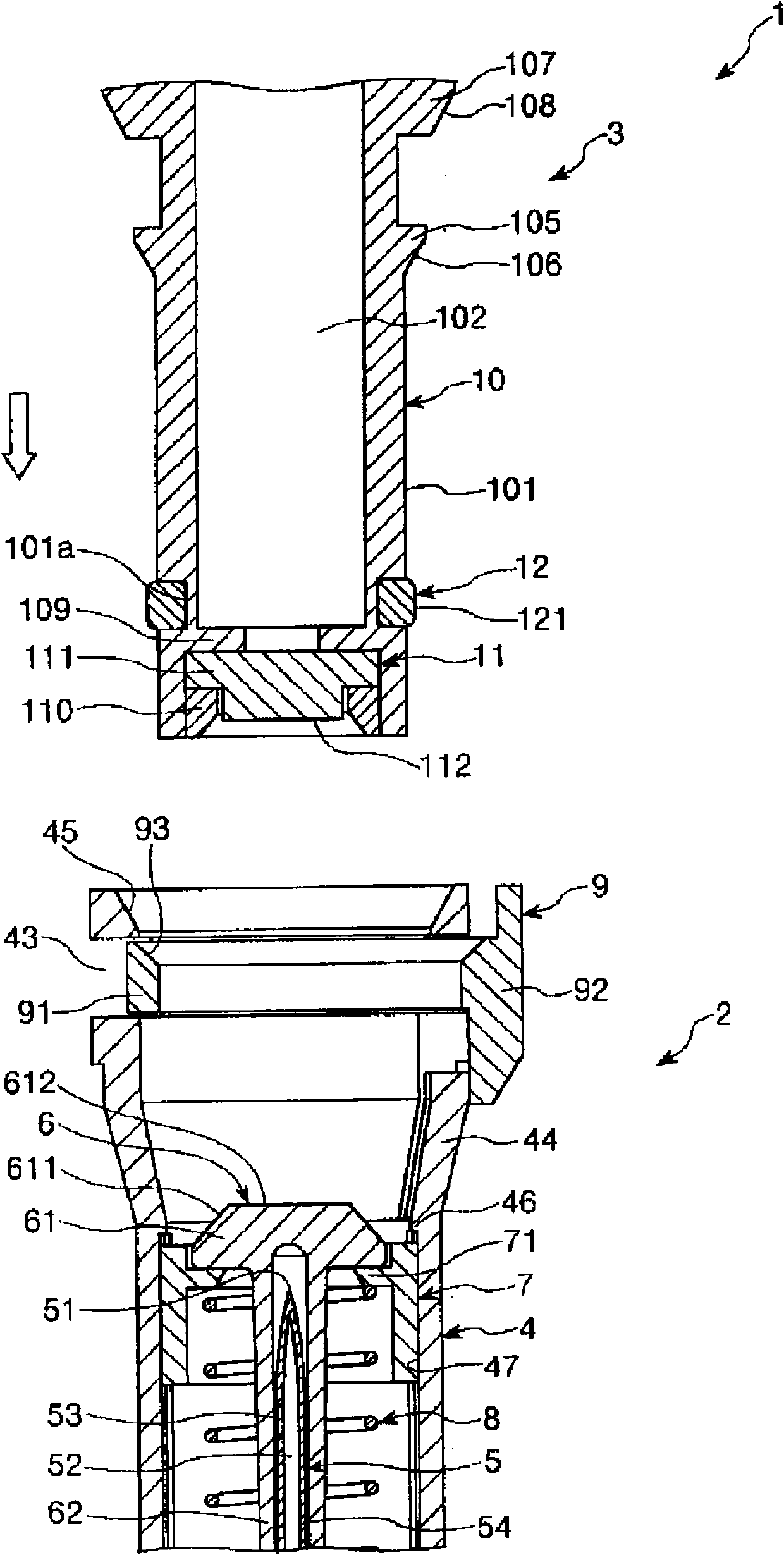

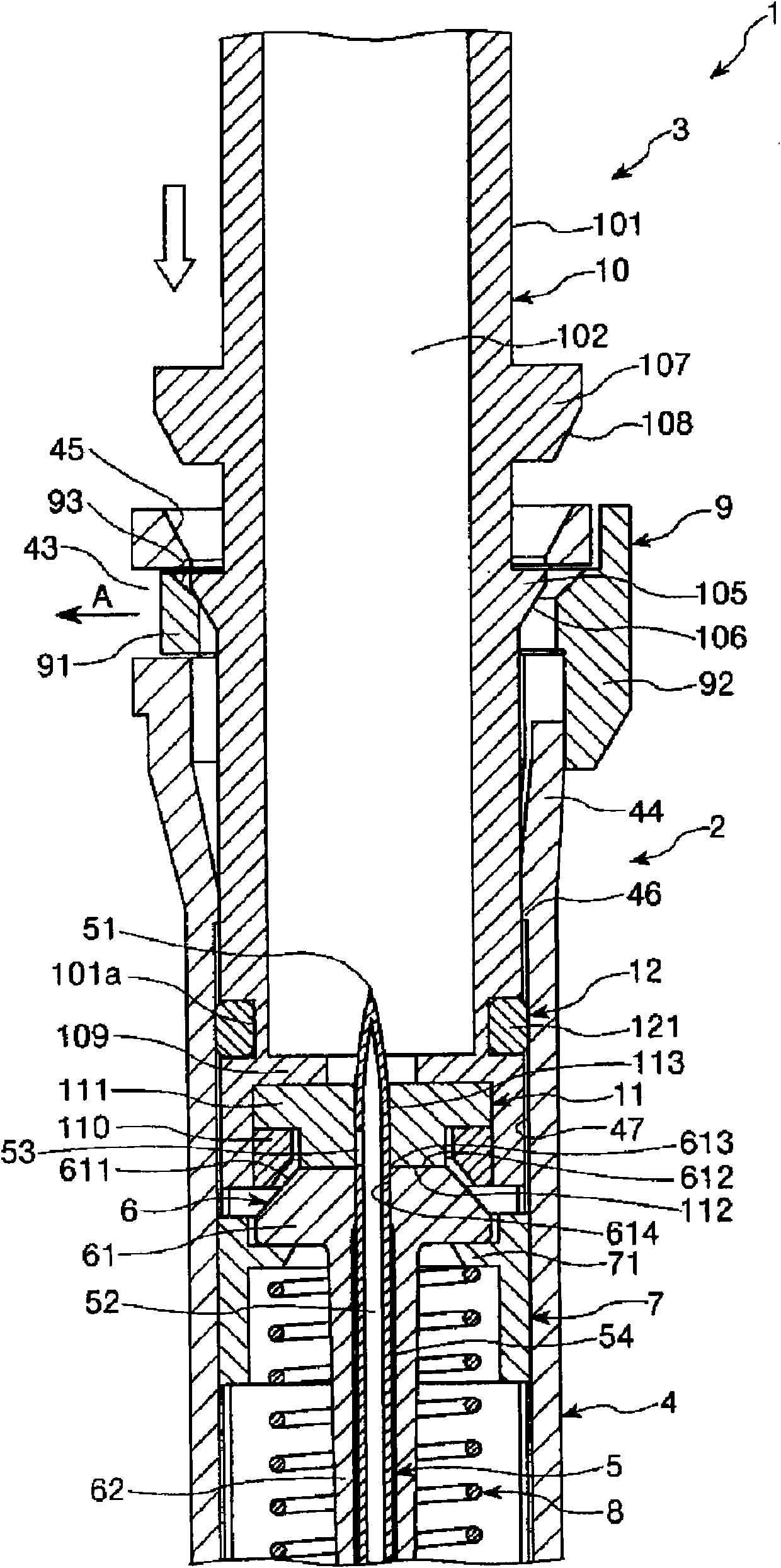

[0078] figure 1 It is an exploded side view of the connector assembly (first embodiment) of the present invention; Figure 2 ~ Figure 4 They are respectively longitudinal sectional views showing the process until the first connector and the second connector in the connector assembly of the present invention are brought into an assembled state (mounted state); Figure 5 ~ Figure 7 means until the Figure 4 A longitudinal sectional view of the process until the shown (assembled state) connector assembly becomes a disassembled state; Figure 8 It is a longitudinal sectional view showing the first connector in the connector assembly (first embodiment) of the present invention; Figure 9 It is a longitudinal sectional view showing the second connector in the connector assembly (first embodiment) of the present invention; Figure 18 is installed in the Figure 8 Partial longitudinal section of the syringe on the first connector shown. In addition, for the convenience of explana...

no. 2 approach

[0163] Figure 10 It is a side view showing the second connector in the connector assembly (second embodiment) of the present invention; Figure 11 It is a cross-sectional view showing the first connector body and the second connector body in an assembled state in the connector assembly (second embodiment) of the present invention.

[0164] Hereinafter, a second embodiment of the connector assembly of the present invention will be described with reference to these drawings, but differences from the above-mentioned embodiment will be mainly described, and descriptions of the same matters will be omitted.

[0165] This embodiment is the same as the first embodiment except that the structure of the second connector body is different.

[0166] exist Figure 10 , Figure 11 In the shown second connector main body 10A, six ribs 13 formed along the longitudinal direction are integrally formed on the outer peripheral portion 101 . Such as Figure 11 As shown, the tops 131 of the ...

no. 3 approach

[0171] Figure 12 It is a partial longitudinal sectional view showing the first connector body and the second connector body in the connector assembly (third embodiment) of the present invention.

[0172] Hereinafter, a third embodiment of the connector assembly of the present invention will be described with reference to these drawings, but differences from the above-mentioned embodiment will be mainly described, and description of the same items will be omitted.

[0173] This embodiment is the same as the first embodiment except that the structures of the first connector body and the second connector body are different.

[0174] Such as Figure 12 As shown, four helical grooves 48 are formed in the inner peripheral portion 47 of the first connector body 4B. In addition, in the second connector main body 10B, four protrusions 14 are protrudingly formed at the front end portion of the outer peripheral portion 101 . In the assembled state, the first connector 2 and the secon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap