Multi-layered structure containing a barrier polymer optionally reinforced against impacts

A multi-layer structure, thermoplastic polymer technology, applied in the direction of substructure, synthetic resin layered products, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

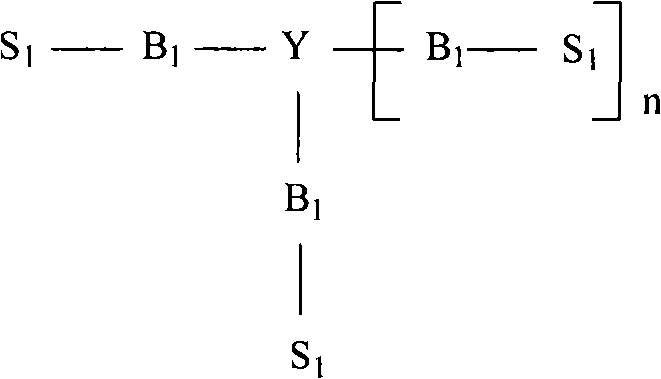

Method used

Image

Examples

no. 1 approach

[0131] Regarding the first embodiment of the multilayer structure, it comprises (from the inside to the outside) the following layers:

[0132] A layer C1 comprising at least one functionalized fluoropolymer optionally blended with at least one compatible fluoropolymer;

[0133] a layer C2 comprising at least one adhesive link;

[0134] a layer C3 comprising at least one polyolefin, preferably polyethylene;

[0135] · layer C4 comprising at least one adhesive link; and

[0136] a barrier layer C5 comprising at least one barrier polymer, optionally impact-modified,

[0137] Said layers are arranged against each other in the order described above.

[0138] Layer C1

[0139] The role of C1 is to chemically protect the other layers. C1 also has a blocking effect. The amount of functionalized fluoropolymer is 1% to 99% by weight (preferably 50% to 10% by weight) of compatible fluoropolymer. 90% by weight).

[0140] Layer C2

[0141] The role of C2 is to facilitate the ...

no. 2 approach

[0154]For the second embodiment of the multilayer structure, it comprises (from the inside to the outside) the following layers:

[0155] · layer C'1 comprising at least one functionalized fluoropolymer optionally blended with at least one compatible fluoropolymer;

[0156] · a barrier layer C'2 comprising at least one barrier polymer, optionally impact-modified;

[0157] A layer C'3 comprising a blend of a thermoplastic polymer, preferably polyethylene, with at least one polyolefin, said thermoplastic polymer being coated with a barrier polymer with C'2 and C'4 the functional groups present react and / or optionally react with the functional groups present on the impact modifier of the barrier polymer; and

[0158] a barrier layer C'4 comprising at least one barrier polymer, optionally impact-modified,

[0159] Said layers are arranged against each other in the order described above.

[0160] Layer C'1

[0161] The properties of layer C'1 are the same as those of C1. The...

Embodiment approach

[0165] According to a preferred embodiment of the first embodiment and its variants and a preferred embodiment of the second embodiment:

[0166] The functionalized fluoropolymer is functionalized PVDF;

[0167] - said fluoropolymer optionally blended with said functionalized fluoropolymer is PVDF;

[0168] C3 or C'3 polyolefin is polyethylene;

[0169] The C4 adhesive link is a thermoplastic polymer with an impact modification that reacts with functional groups present on the C5 barrier polymer and / or optionally with the C5 barrier polymer chemical functional groups that react with functional groups present on the agent; and

[0170] The barrier polymer of C5, C'2 and C'4 is EVOH;

[0171] • The thermoplastic polymers of C2, C3, C4 and C'3 are functionalized polyolefins.

[0172] Preferably, the functionalized fluoropolymer is PVDF to which an anhydride, preferably maleic anhydride, has been radiation grafted. The fluoropolymer extrudes very well and also has excellent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com