Twin skeg ship

A technology of skeg and fin plate, which is applied in the field of double skeg boats, can solve the problems of not being applicable to double skeg boats, and achieve the effect of increasing wake revenue and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

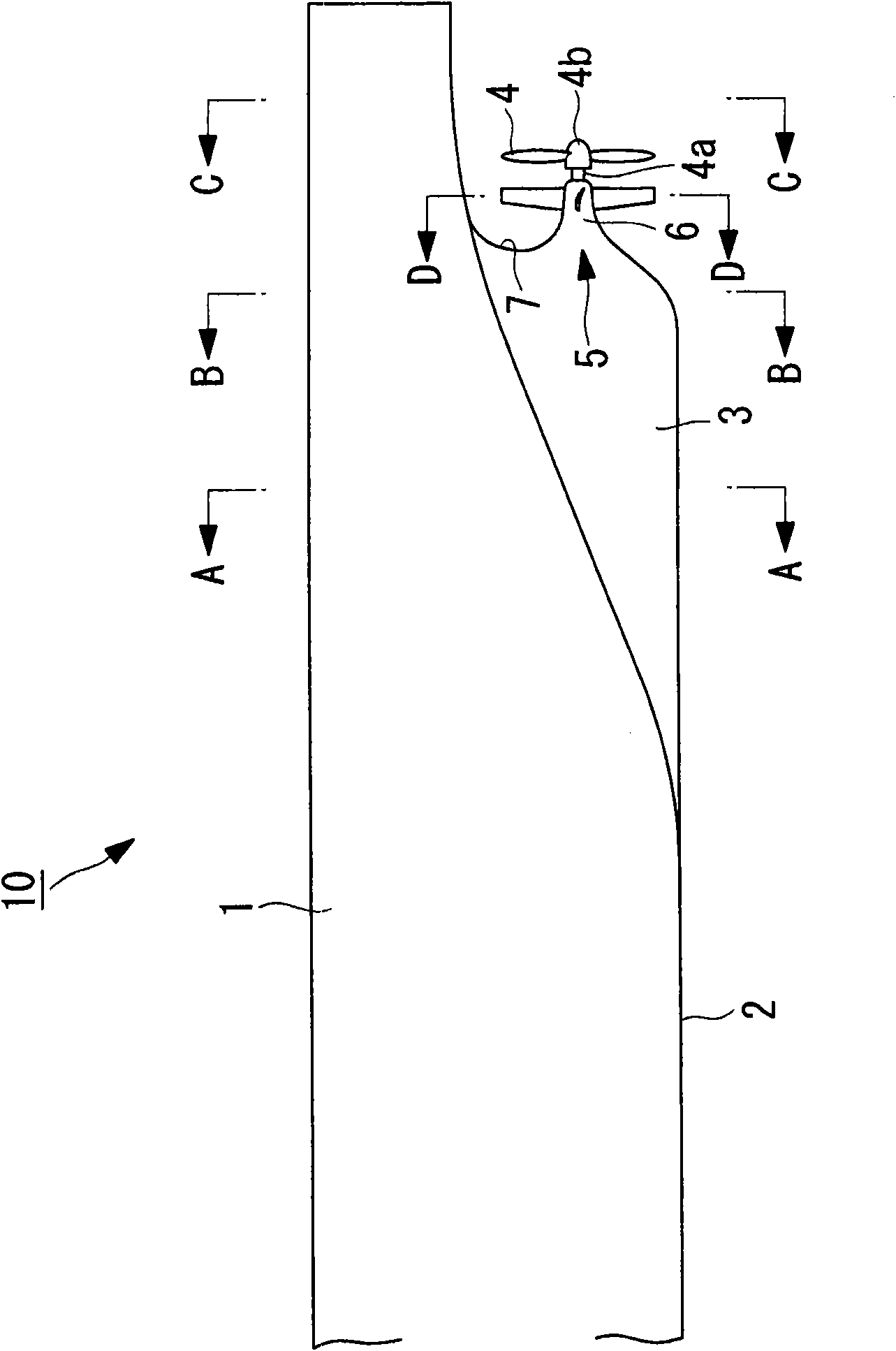

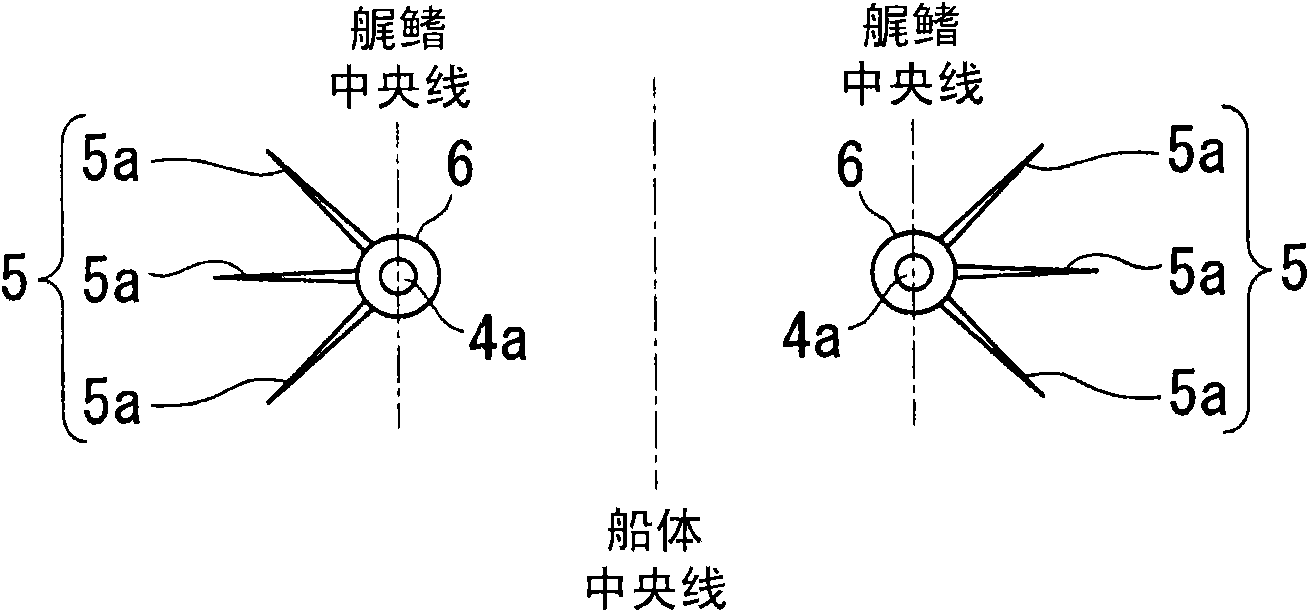

[0044] figure 1 It is the left side view seen from the port side of the stern side of the twin-skeg ship 10 of this embodiment, figure 1 The reference numeral 1 is the hull, the reference numeral 2 is the bottom, the reference numeral 3 is the skeg, the reference numeral 4 is the propeller (propeller wing), the reference numeral 4a is the propeller shaft, and the reference numeral 5 is the reaction fin . In addition, in order to realize the simplification of the drawing, the rudder is in figure 1 Not indicated in.

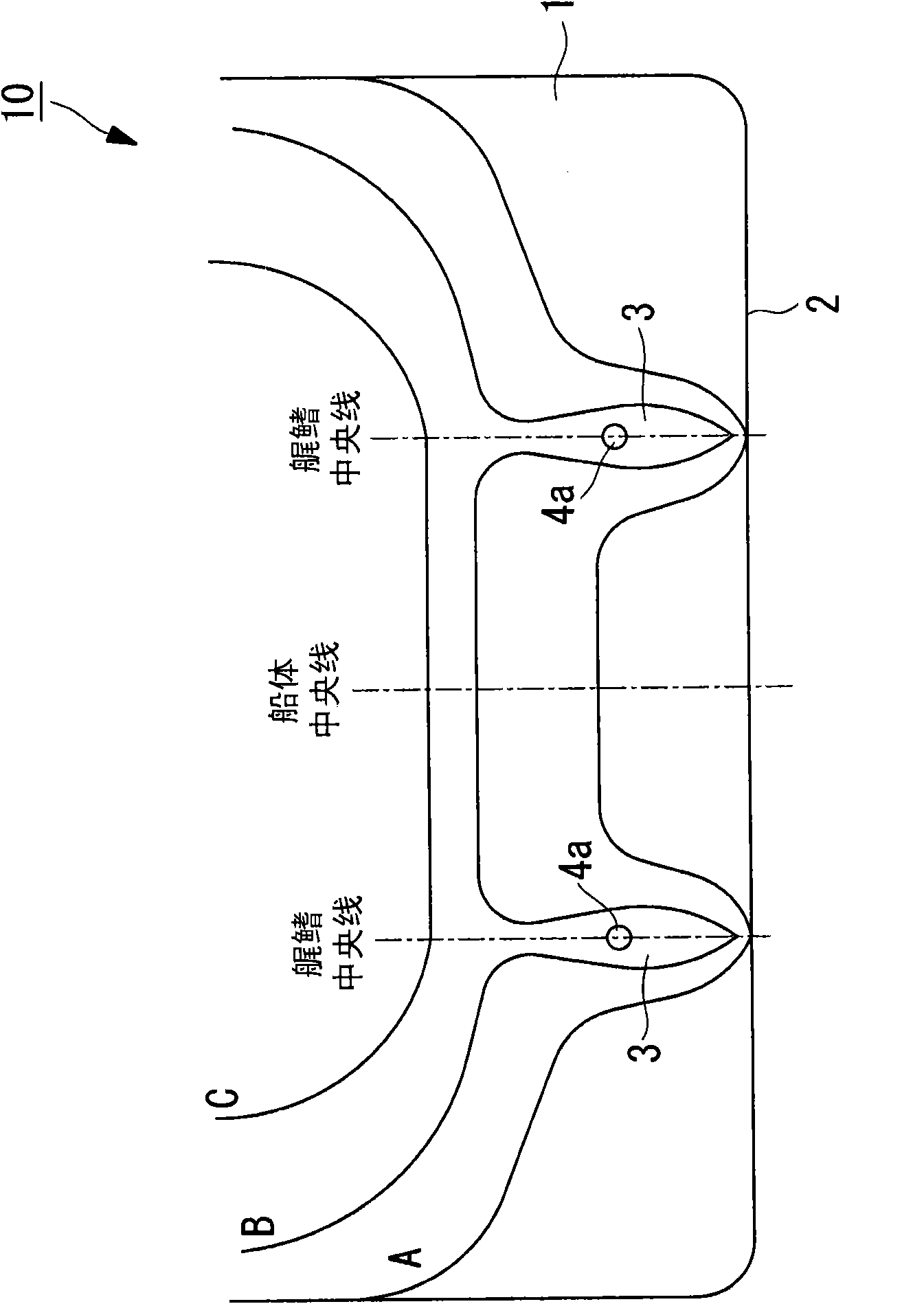

[0045] figure 2 yes means figure 1 The shown hull 1 is shown along A-A to line of sight, B-B to line of sight and C-C to the line of sight of the section cut off in the ship width direction, each section corresponding to A-A line of sight, B-B line of sight and C-C line of sight is given an appended Diagram labeled A, B, C. Such as figure 2 As shown, the twin-skeg ship 10 has a pair of left and right skegs 3 protruding downward from the ship bottom 2 const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com