Dust collector reel

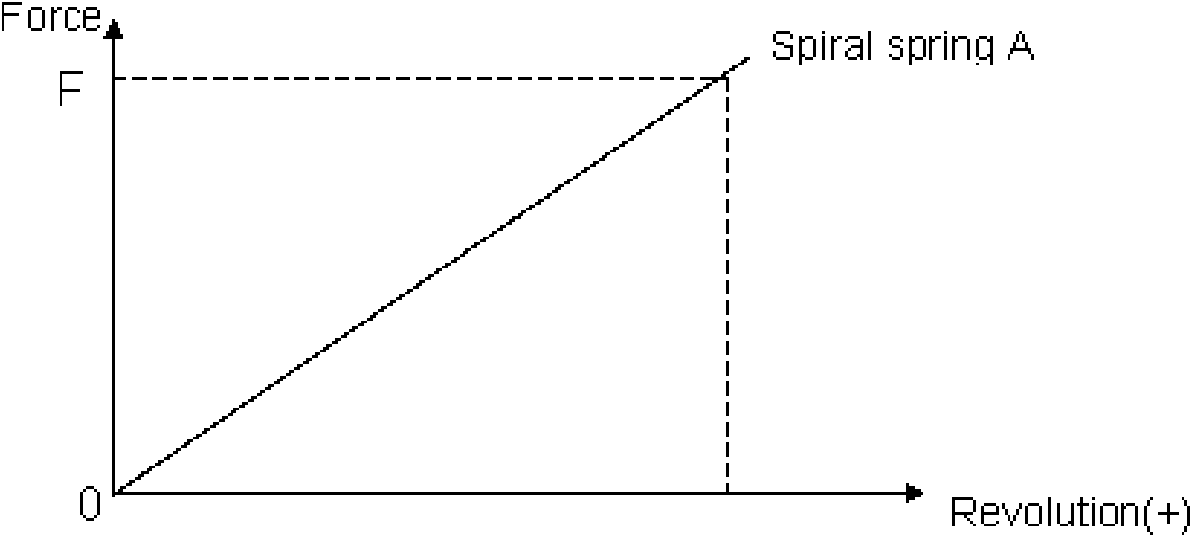

A technology of wire reels and vacuum cleaners, which is applied in the direction of electrical components, cable arrangement between relative moving parts, and cable installation. It can solve the problems of poor power line rotation and vacuum cleaners cannot stabilize the return line at a uniform speed, and achieve constant output. Uniform force and pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

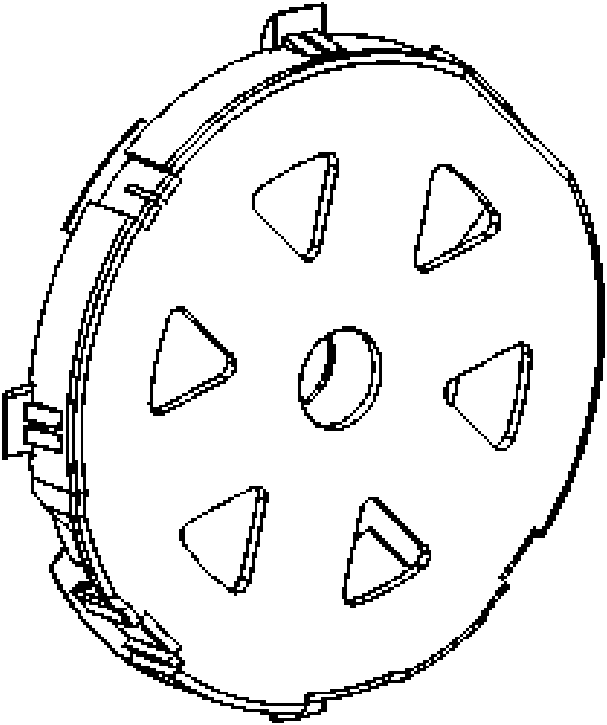

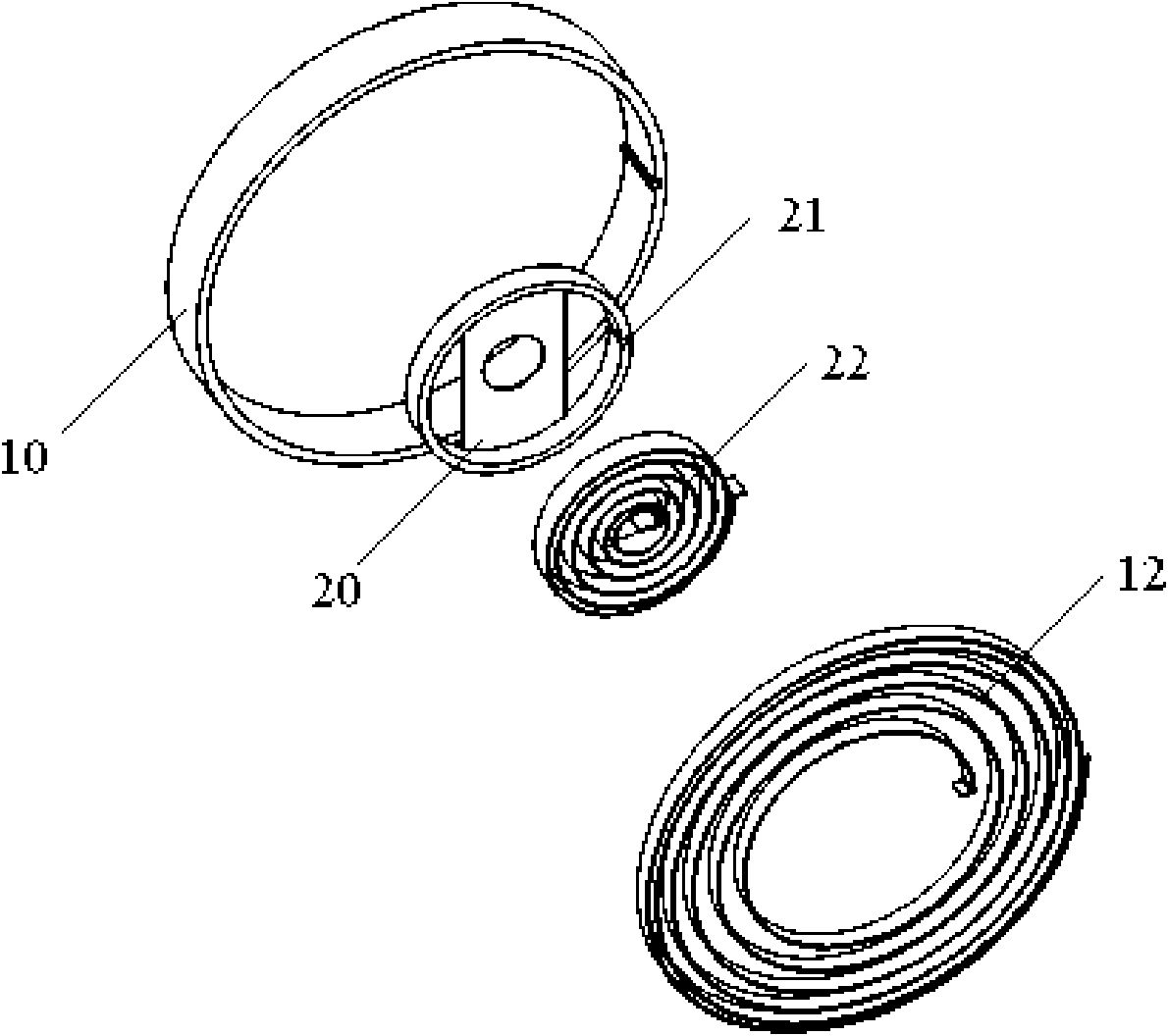

[0028] image 3 It is a three-dimensional exploded schematic diagram of an auxiliary driving mechanism in the present invention; Figure 4 It is a three-dimensional combined schematic view of the present invention provided with an auxiliary driving mechanism; Figure 5 It is a plan combination schematic view of the present invention provided with an auxiliary driving mechanism. Embodiment 1: Now take a main driving mechanism and an auxiliary driving mechanism arranged horizontally as an example for illustration, and the auxiliary driving mechanism includes a coaxial and horizontally arranged main driving mechanism 10 and a first auxiliary driving mechanism 20, two of which The coil springs in the drive mechanism are connected in series and arranged concentrically. The diameter of the coil spring of the main drive is greater than the diameter of the coil spring in the auxiliary drive mechanism. The outside of the coil spring 12 of the main drive mechanism 10 is clamped on the ...

Embodiment 2

[0029] Image 6 It is a three-dimensional exploded schematic view of the present invention with two auxiliary drive mechanisms; Figure 7 It is a schematic plan view of the present invention with two auxiliary drive mechanisms. Embodiment 2: Now take two auxiliary drive mechanisms arranged horizontally as an example for illustration. The reel includes a main drive mechanism 10, a first auxiliary drive mechanism 20 and a second auxiliary drive mechanism 30 arranged coaxially and horizontally. The coil springs in the mechanism are connected in series and arranged concentrically, the diameter of the coil spring in the main driving mechanism is the largest, the diameter of the coil spring in the second auxiliary driving mechanism is next, and the diameter of the coil spring in the first auxiliary driving mechanism is the smallest, so The reel box includes a main drive mechanism 10, a first auxiliary drive mechanism 20, and a second auxiliary drive mechanism 30 arranged coaxially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com