Remote control model locomotive

A locomotive and model technology, applied in the field of remote control model locomotives, can solve problems such as inability to respond to rear wheels in real time, strain, abnormal shaking of model locomotives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

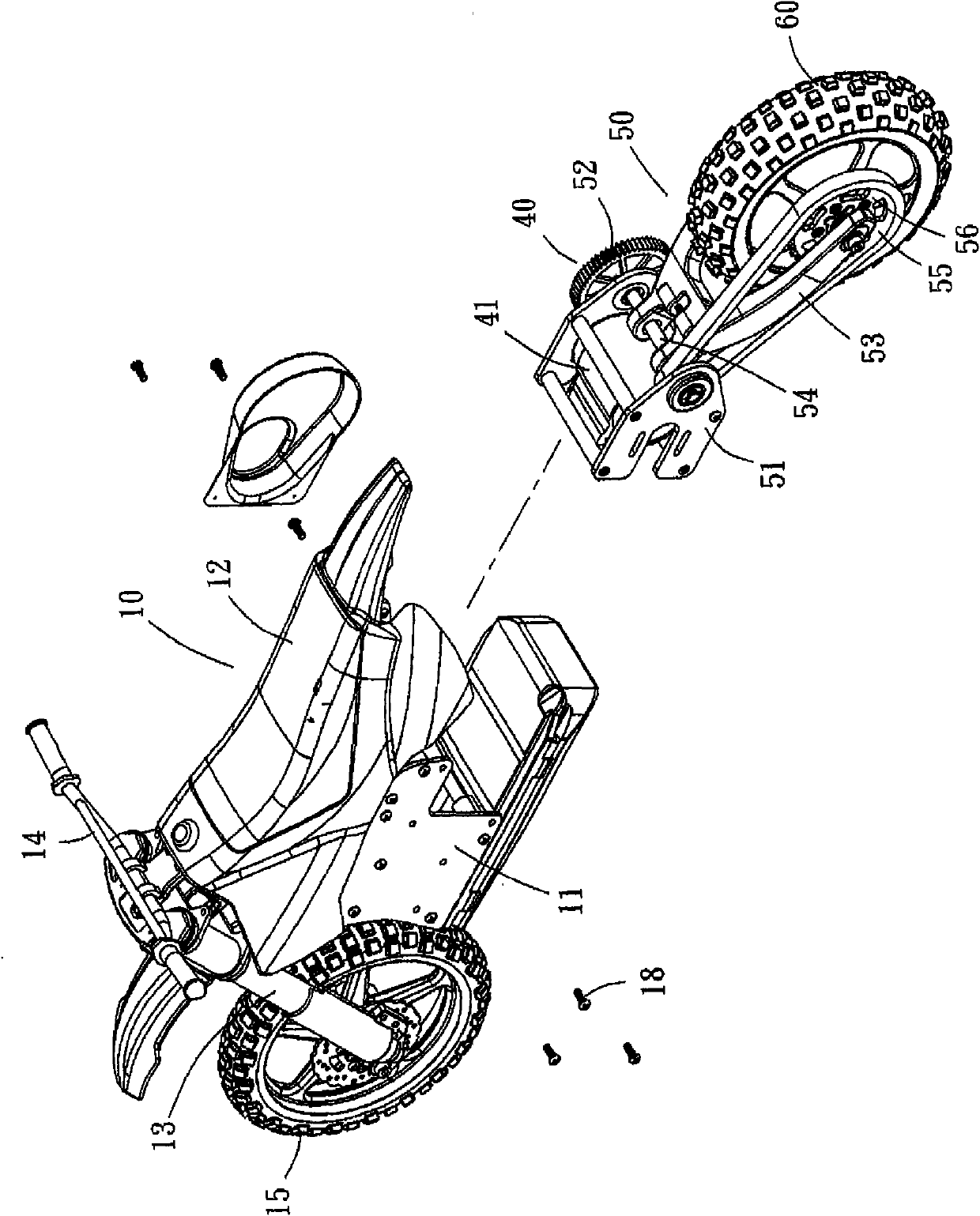

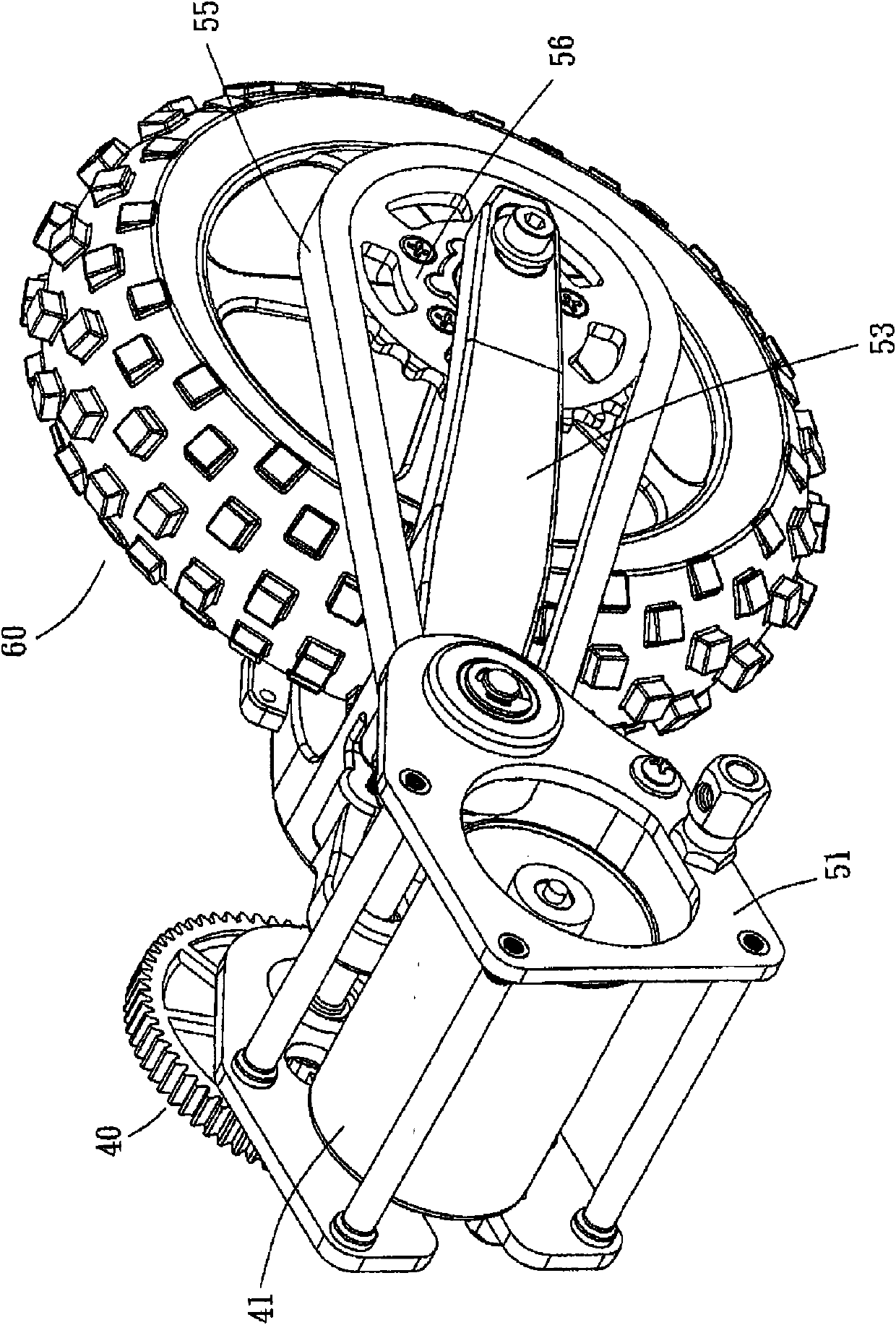

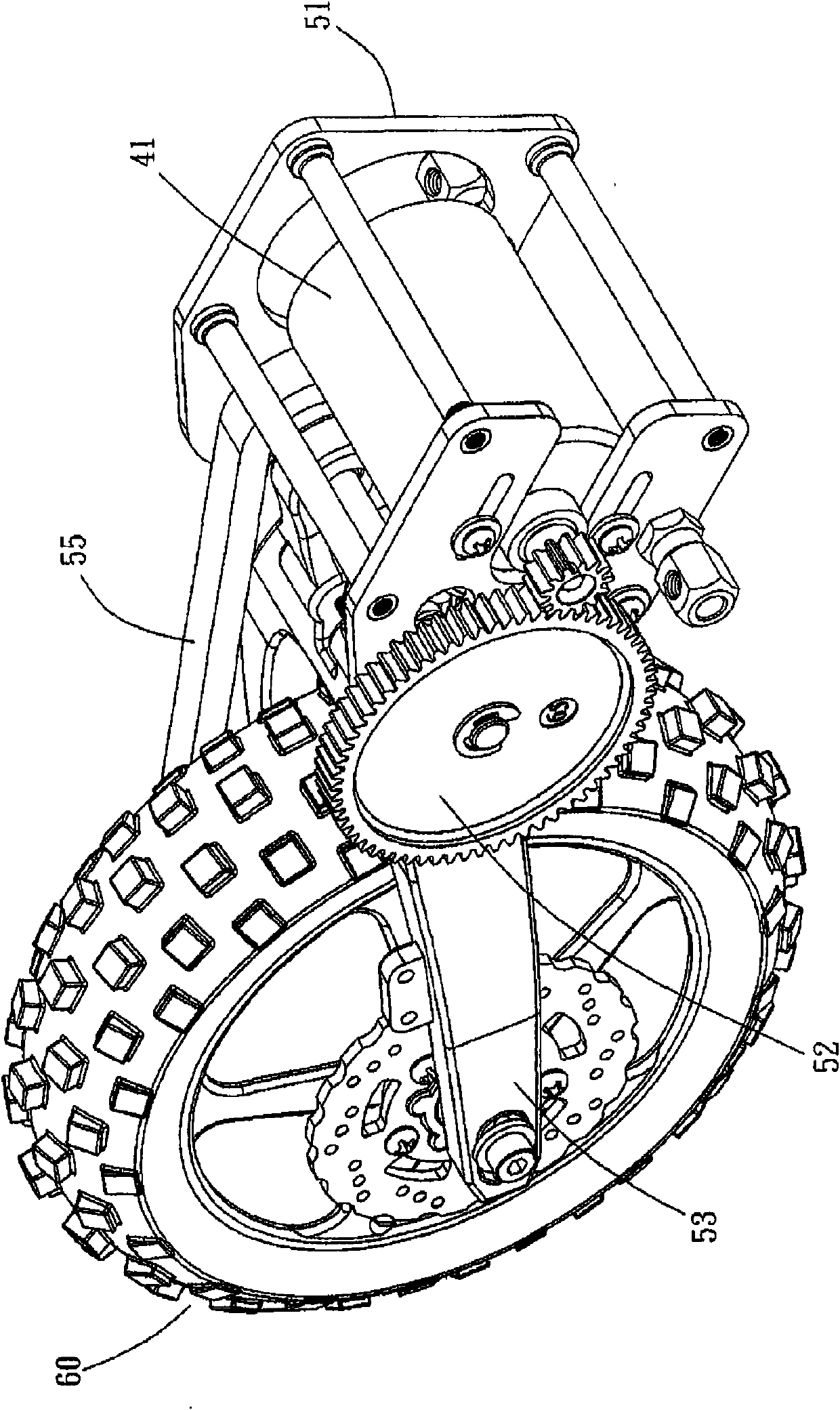

[0043] see Figure 1 to Figure 6 As shown, a remote control model locomotive provided by the embodiment of the present invention includes a front body 10, a rear body 50 and a power output device 40, wherein the front body 10 has a front frame 11, and the front frame The upper end of 11 is a cushion 12, a rider (not shown on the figure) can be installed on the cushion 12 in practice, and the front frame 11 and the cushion 12 are provided with a front suspension 13 and a steering faucet 14 in the common front, and the front suspension 13 below A front wheel 15 is provided; the rear body 50 is integrated with the front body 10 in a detachable manner. During assembly, the rear vehicle frame 51 of the rear vehicle body 50 is just fitted with the front vehicle frame 11 of the front vehicle body 10 and combined with each other by a plurality of screws 18 to form a group. The rear end of the rear frame 51 of the rear vehicle body 50 is a rear suspension 53 and a rear wheel 60 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com