Novel cosmetic packaging can

A technology for cosmetics and packaging cans, applied in the field of new cosmetic packaging cans, can solve the problems of inconvenient use, inability to use up materials completely, uneven cosmetics, etc., and achieve the effects of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

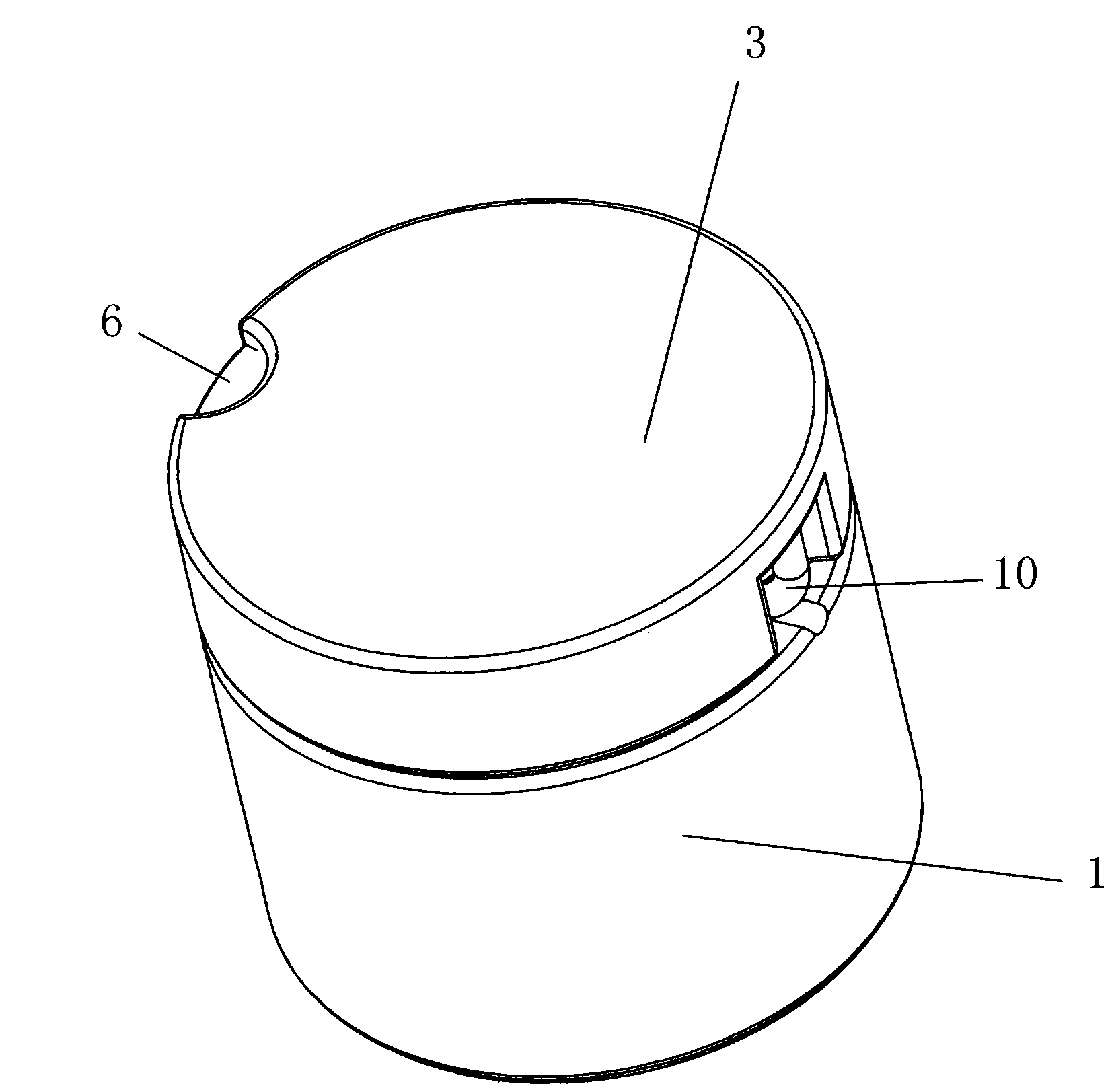

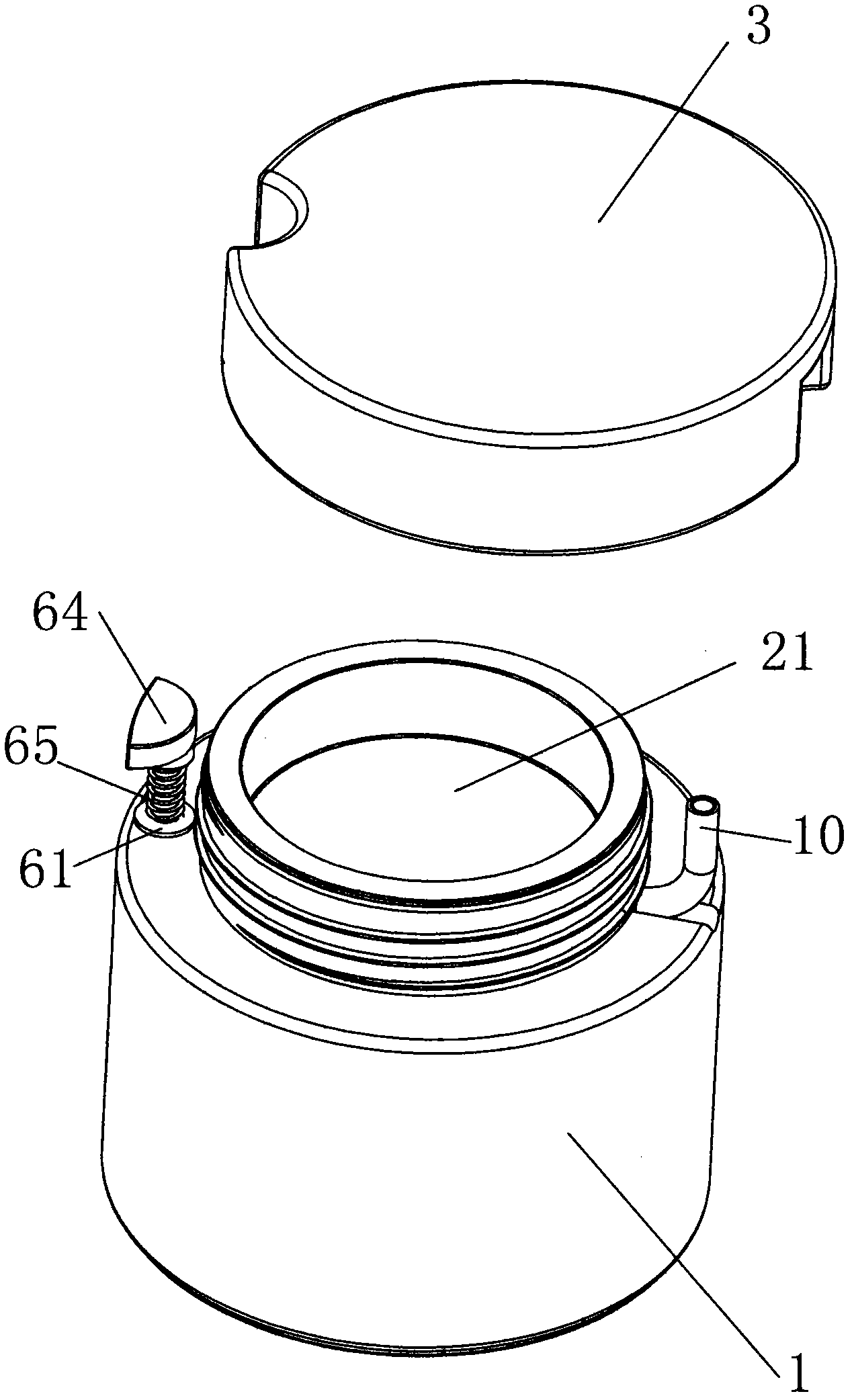

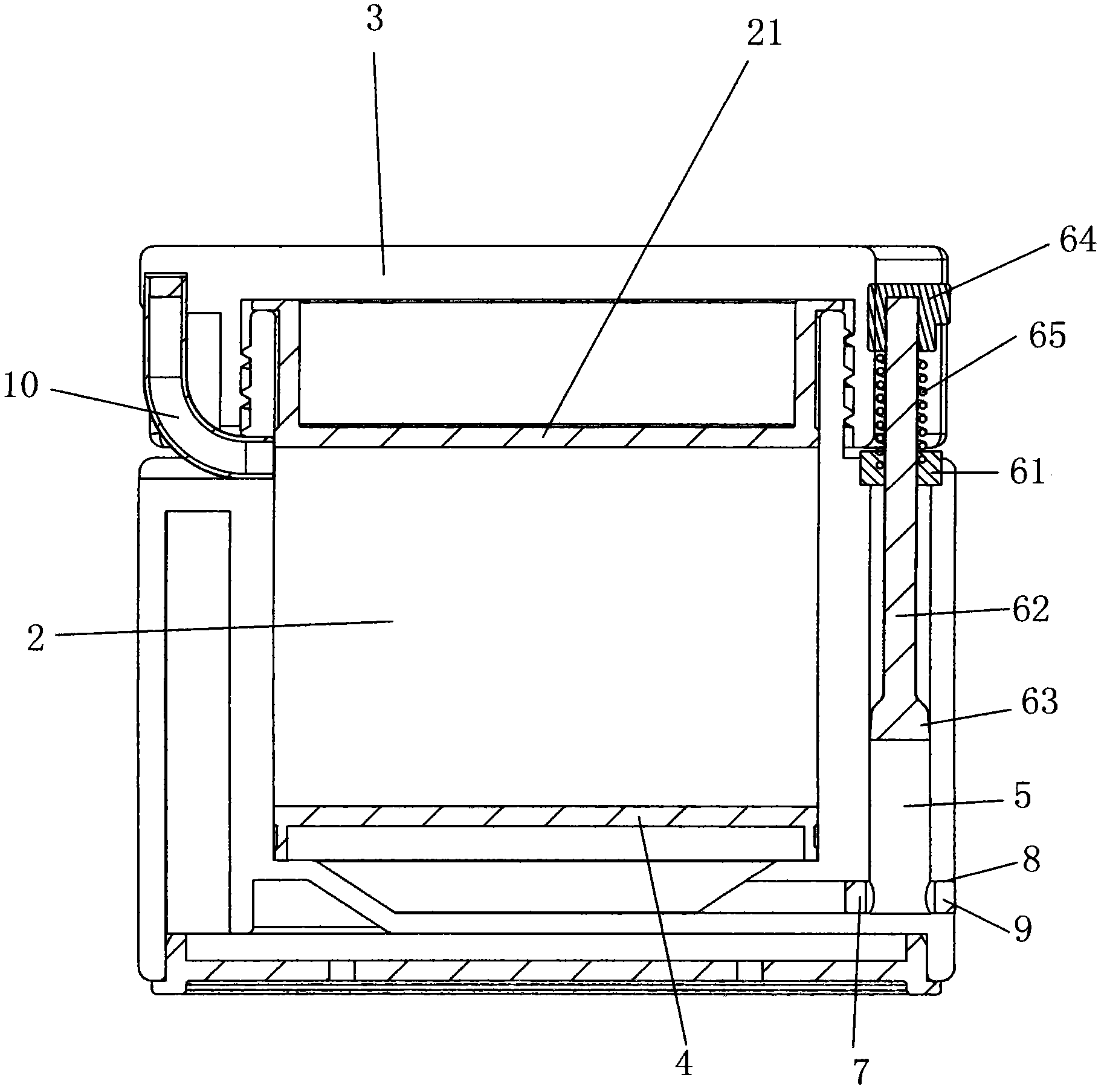

[0012] A new type of cosmetic packaging tank, which includes a tank body 1, a tank body 1 is provided with a cavity 2, the upper end of the cavity 2 is movably connected with a tank cover 3, and a movable plate 4 is provided in the cavity 2, and materials are contained in the cavity 2 and moved Above the plate 4, the lower end of the movable plate 4 on the cavity 2 is provided with an air intake channel 5, and the other end of the air intake channel 5 is provided with an inflatable device 6 that can inflate the air intake channel 5, and the air intake channel 5 An air intake check valve 7 is provided on the air intake passage 5, and an air supply inlet 8 communicating with the outside world is also provided between the air intake check valve 7 and the inflator 6 on the air intake channel 5, and the air supply inlet 8 is provided with an air supply The one-way valve 9, the upper part of the cavity 5 is also connected with a discharge pipe 10. The inflatable device is used to pu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap