Aluminum alloy wheel gravity casting die and casting method thereof

A gravity casting, aluminum alloy technology, applied in casting equipment, manufacturing tools, equipment for feeding molten metal into molds, etc., can solve the problems of large machining allowance, many artificial factors, and many aluminum alloy wheel risers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

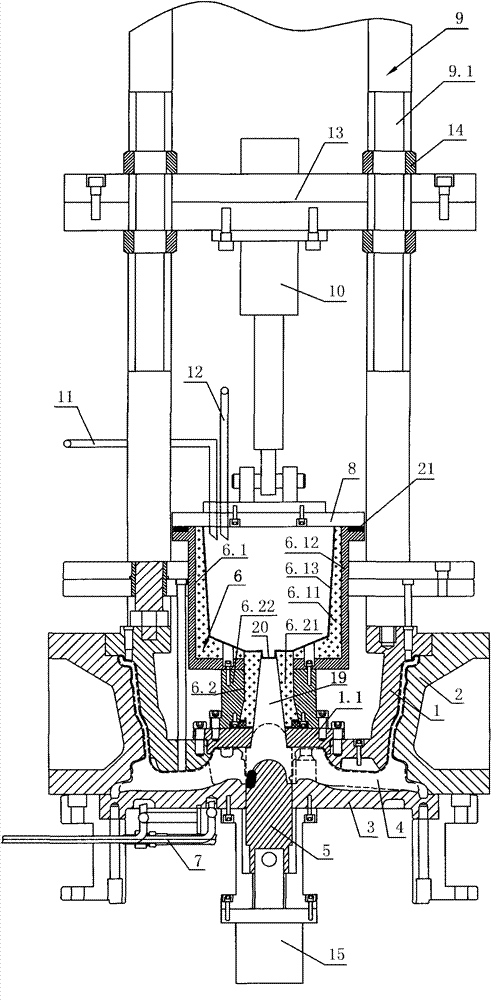

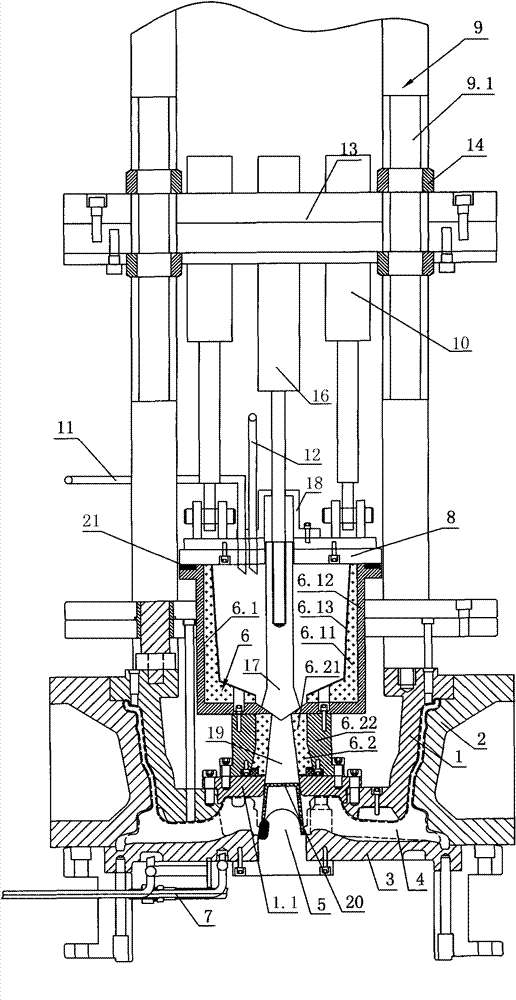

[0029] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

[0030] Such as figure 1 Shown is a schematic cross-sectional structure diagram of an aluminum alloy wheel gravity casting mold according to an embodiment of the present invention. The gravity casting mold for aluminum alloy wheels of this embodiment includes a cooling device 7, a top mold 1, a side mold 2, a bottom mold 3, and a mold cavity 4 formed by the top mold 1, the side mold 2 and the bottom mold 3. The bottom mold 3 is provided with a shunt cone 5. The said aluminum alloy wheel gravity casting mold also includes a thermos cup 6 communicating with the mold cavity 4 and capable of storing molten aluminum, and a pressurizing device that can continuously inject the molten aluminum stored in the thermos cup 6 into the mold cavity 4 , A blocking device that can prevent the molte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com