Method for manufacturing buoyancy tanks of semi-submerged ship

A production method and technology for semi-submersible ships, which are used in ship parts, ship construction, ships, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

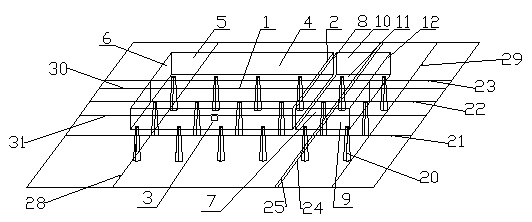

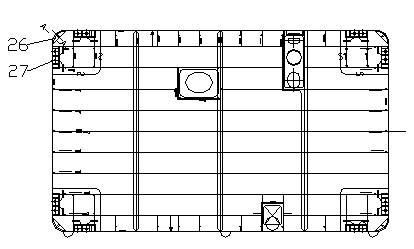

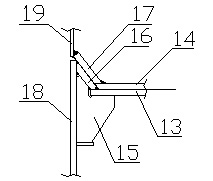

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] The present invention comprises the following steps:

[0030] 1) Use a total station on a fetal position to draw the active tire frame center line 22, ground sample alignment lines 30 and 31, upper bottom end line 24 and top end line 29 of the upper float box, upper top end line 25 and lower bottom end line 28 of the lower float box , the distance between the position line 24 and the position line 25 between the lower bottom of the upper pontoon tank and the upper top of the lower pontoon tank is controlled within 1 mm to 4 mm;

[0031] 2) Make six dough pieces for the upper floating tank and six dough pieces for the lower floating tank on the platform;

[0032] 3) Lift the upper buoyancy tank and the lower buoyancy tank respectively to build buoyancy tanks with six facets;

[0033] 4) Complete the installation and welding of the limit chute of the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com