Mechanism for automatically regulating space of knocking-over bar of warp knitting machine

A technology of automatic adjustment and stripping board, applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of wasting manpower, material resources, and reducing work efficiency, so as to improve work efficiency, reduce inefficiency and limitations , the effect of reducing labor time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

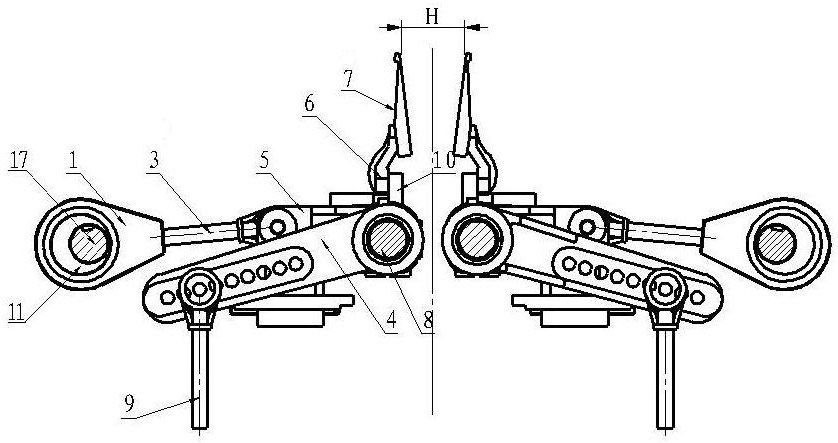

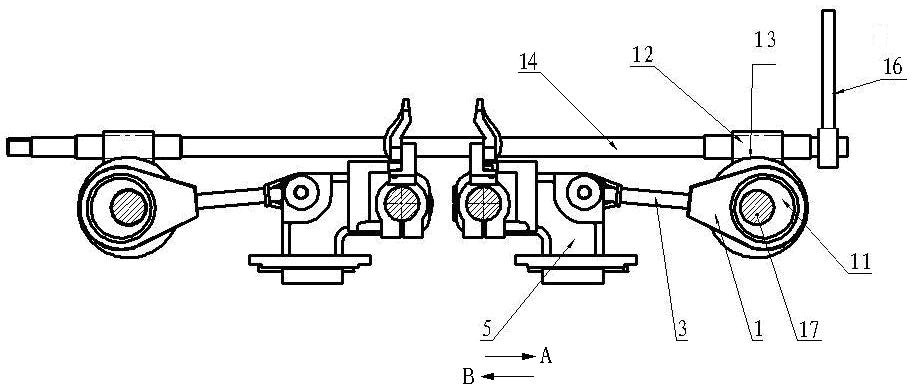

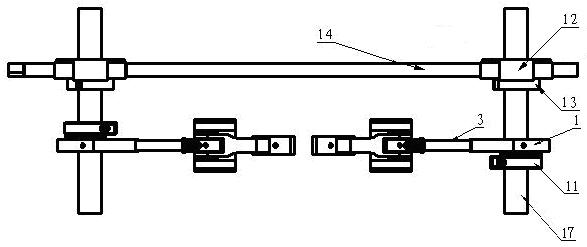

[0023] Such as figure 1 , figure 2 , image 3 , a warp knitting machine stripping plate spacing automatic adjustment mechanism, the stripping plate 7 is fixed on the connecting seat 6 by screws, the fixing seat 10 is installed on the swing shaft 8 together with the swing arm 4, and can rotate around the swing shaft 8, The swing shaft 8 is fixed on the body (not shown in the figure). The swing arm 4 is connected to the transmission part through the connecting rod 9, and the movement of the transmission part drives the movement of the connecting rod 9 and the swing arm 4, and thus causes the movement of the fixing seat 10 and the knock-out plate 7 fixed thereon, so as to realize normal Braiding movement.

[0024] On the balance shaft 8 on which the stripping plate 7 and the fixed seat 10 are installed, the balance shaft seat 5 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com