Multi-station weaving and twisting method

A multi-station, twisting technology, applied in the field of textile twisting, can solve the problems of unable to transport the hinged frame, unable to adjust the placement position of the hinged frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

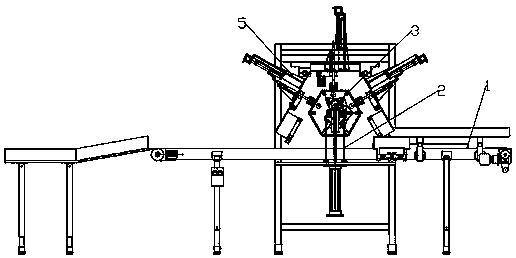

[0140] This embodiment discloses a multi-station braiding method, including a twisting frame conveying station 1, a twisting frame lifting station 2, a twisting frame rotating station 3, a twisting wire feeding station 409, and a twisting station 5.

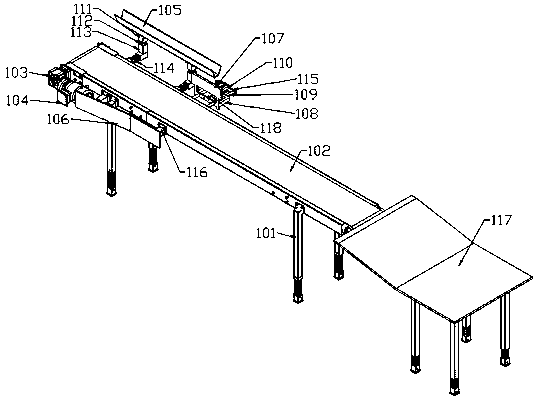

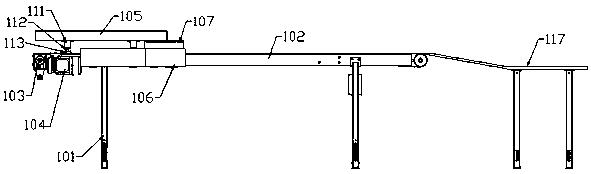

[0141] The twisted frame is placed on the conveyor belt 102, and the rollers 122 of the twisted frame are placed inside the guide groove 105 arranged along the conveying direction of the conveyor belt 102;

[0142] During the transportation process of the twisted frame, the vertically arranged regular inclined plate 106 limits one end of the twisted frame; the regular splint 107 moving in the horizontal direction regulates the other end of the twisted frame, so as to keep the two ends of the twisted frame in the conveying process in line with the other end of the twisted frame. The conveyor belts 102 are parallel.

[0143] Cylinder Ⅰ 202 drives cylinder guide rod Ⅰ 204 to lift upward, and cylinder Ⅱ 203 drives cylinder guide rod...

Embodiment 2

[0152] The twisted frame includes a hexagonal wooden frame 120, a central shaft 121 is set through the hexagonal wooden frame 120, and a roller 122 is provided at one end of the central shaft 121; 123.

[0153] This embodiment discloses a multi-station braiding machine, which includes a kink frame conveying station 1 , a kink frame lifting station 2 and a kink frame rotating station 3 .

[0154]Described winch conveying station 1 comprises the conveyer belt mechanism that is arranged on the belt conveyor frame 101, and described conveyer belt mechanism comprises conveyer belt 102 and the belt conveying speed reducer 103 that is connected with conveyer belt 102 and belt conveying motor 104; Said conveyer belt The mechanism also includes a guide groove 105 arranged along the conveying direction of the conveyor belt 102, the guide groove 105 is located on one side of the conveyor belt 102, and a vertically arranged regular inclined plate 106 is arranged on the other side of the c...

Embodiment 3

[0160] The twisted frame includes a hexagonal wooden frame 120, a central shaft 121 is set through the hexagonal wooden frame 120, and a roller 122 is provided at one end of the central shaft 121; 123.

[0161] This embodiment discloses a multi-station braiding machine, which includes a kink frame conveying station 1 , a kink frame lifting station 2 and a kink frame rotating station 3 .

[0162] Twisted frame conveying station 1 comprises the conveyer belt mechanism that is arranged on the belt conveyer frame 101, and described conveyer belt mechanism comprises conveyer belt 102 and is connected with conveyer belt 102 belt conveying speed reducer 103 and belt conveying motor 104; Described conveyer belt mechanism also It includes a guide groove 105 arranged along the conveying direction of the conveyor belt 102, the guide groove 105 is located on one side of the conveyor belt 102, and the other side of the conveyor belt 102 is provided with a vertically arranged regular inclin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com