Concrete pavement curing agent atomizing and spraying machine

A concrete pavement and curing agent technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of low curing agent efficiency and great harm to spraying workers, and achieve the effects of avoiding poisoning, reducing environmental pollution, and improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

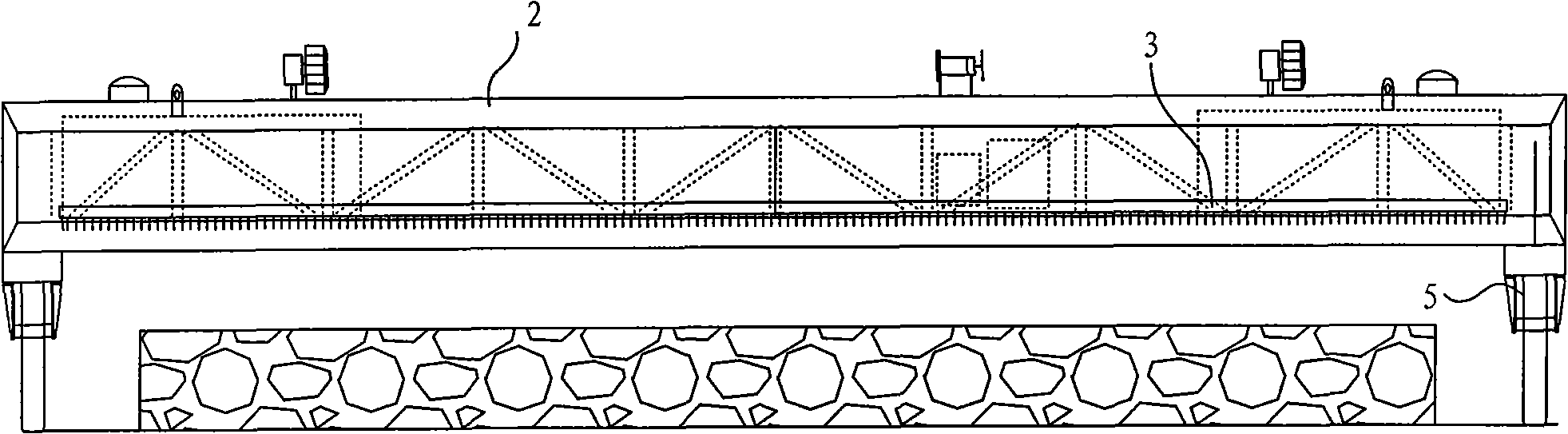

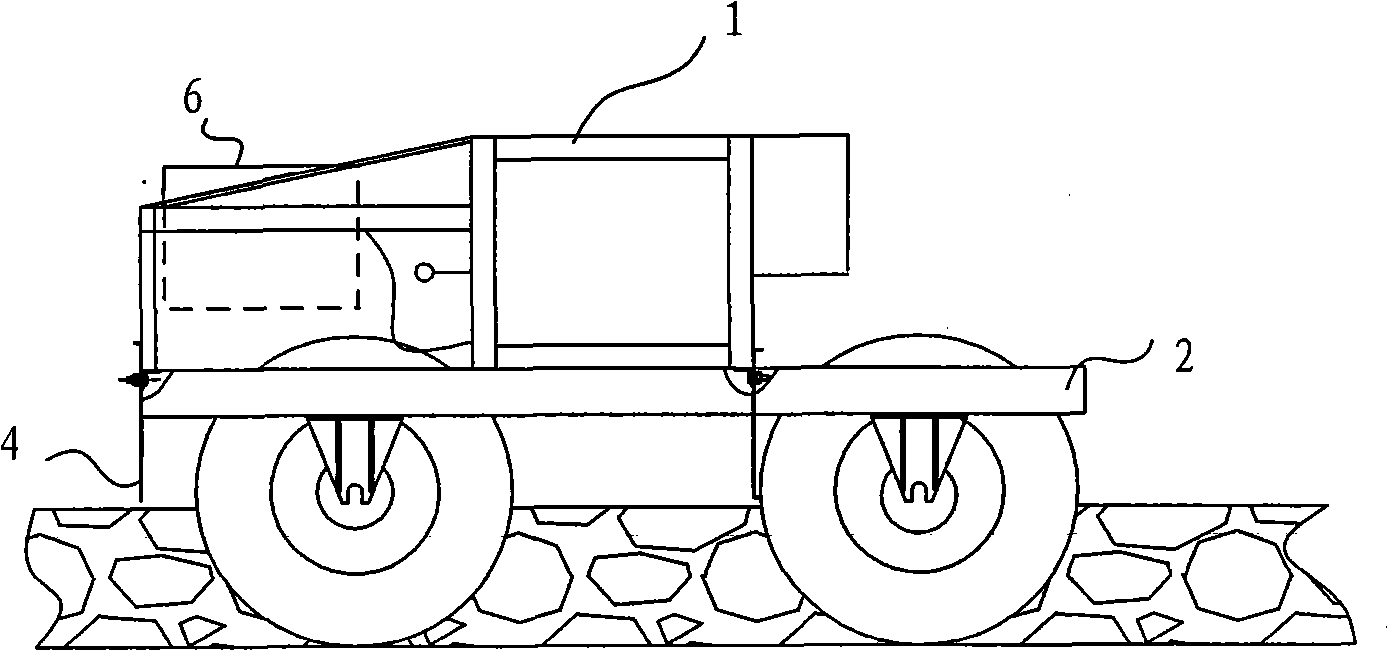

[0037] Figure 1A It is a schematic diagram of the front partial structure of the concrete pavement maintenance agent atomization sprayer provided by Embodiment 1 of the present invention, Figure 1B The schematic diagram of the side overall structure of the concrete pavement maintenance agent atomizing sprayer provided in Embodiment 1 of the present invention, as shown in Figure 1A and Figure 1B As shown, the concrete pavement maintenance agent atomization sprayer includes: a frame 1, a running device 5 is arranged on both sides of the frame 1, a bridge frame 2 is arranged on the running device 5, and the two sides of the bridge frame 2 The ends are respectively fixed with the running gear 5 on both sides; for example: the running gear can be divided into three forward gears under the control of the operator on the control cabinet, and one reverse gear automatically walks.

[0038] A spraying system 3 for spraying concrete road surface maintenance agent is arranged under th...

Embodiment 2

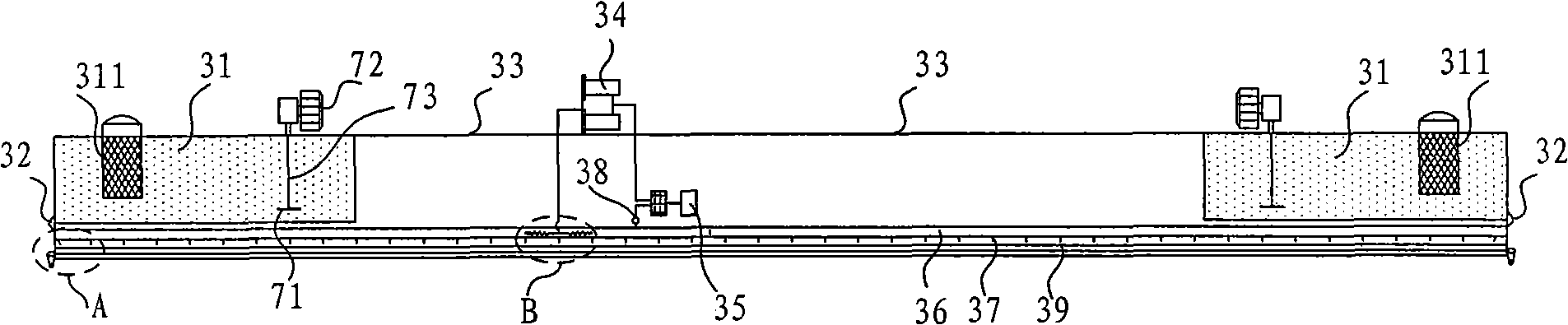

[0042] Figure 2A The structural schematic diagram of the spraying system of the concrete pavement maintenance agent atomizing sprayer provided for the second embodiment of the present invention, as Figure 2A As shown, on the basis of Embodiment 1, further, the spraying system of the concrete pavement maintenance agent atomization sprayer includes: at least two liquid storage tanks 31 for holding the sprayed concrete pavement maintenance agent, the A first ball valve 32 is installed on the side of the bottom of the liquid storage tank 31, and the first ball valve 32 is connected to a filter 34 through a pipeline 33, and the filter 34 is connected to a laterally arranged spray pipe 36 through a liquid pump 35. The liquid pump 35 is connected with the spray pipe 36 by a second ball valve 38, and more than one nozzle 37 is connected below the spray pipe 36, and the spraying direction of the nozzle 37 of the spray pipe 36 is downward, which can be controlled by the second ball va...

Embodiment 3

[0050] Figure 3A The structural schematic diagram of the walking device of the concrete pavement maintenance agent atomization sprayer provided by Embodiment 3 of the present invention, as shown in Figure 3A As shown, on the basis of Embodiment 1 and Embodiment 2, further, the walking device of the concrete road maintenance agent spraying machine may include at least two road wheels 51 and be used to control the speed and direction of the road wheels 51 The driving device 52. The speed and direction of rotation of the road wheels 51 can be independently driven by the respective driving devices 52 , or the speed of rotation and the direction of rotation of the road wheels 51 on both sides can be controlled by one driving device. The two ends of the bridge frame 2 can be respectively installed on the top of the running gear 1 on both sides. in, Figure 3B The schematic diagram of the structure of the driving device in the walking device of the concrete pavement maintenance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com