Transverse test loading mechanism

A technology of loading mechanism and guiding mechanism, which is applied in vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as failure to meet the reliability evaluation requirements of the reaction rod assembly, and achieve comprehensive reliability evaluation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

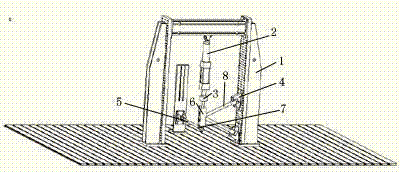

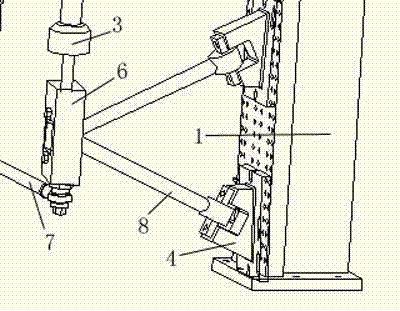

[0008] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 As shown, the lateral test loading mechanism is composed of a gantry 1, an actuator 2, a large-end loading mechanism 3, a small-end support 4 and a guiding mechanism 5, and the top of the gantry 1 is fixed with an actuator 2, which is characterized in that: The lower part of the actuator 2 is connected with a large-end loading mechanism 3, the small-end support 4 is fixedly connected with the gantry 1, one end of the V-bar assembly 8 is fixed on the large-end loading mechanism 3, and the other end is fixed on the small-end support 4 Above, the big-end loading mechanism 3 is composed of a transverse fixture 6, a spacer and a guide screw 7; the spacer is plugged into the hole of the transverse fixture 6, the big-end loading mechanism 3 and the transverse fixture 6 are connected by bolts, and the lead screw 7 is used to support The lower end of the ball pin of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com