Heat insulator for a vehicle exhaust pipe and methods for manufacturing the same

A manufacturing method and a technology for an exhaust pipe, which are applied to exhaust devices, mufflers, surface coverings, etc., can solve the problems of insufficient thermal insulation and thermal insulation functions of the thermal insulation body, and achieve the effects of shortening the light-off time and excellent thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

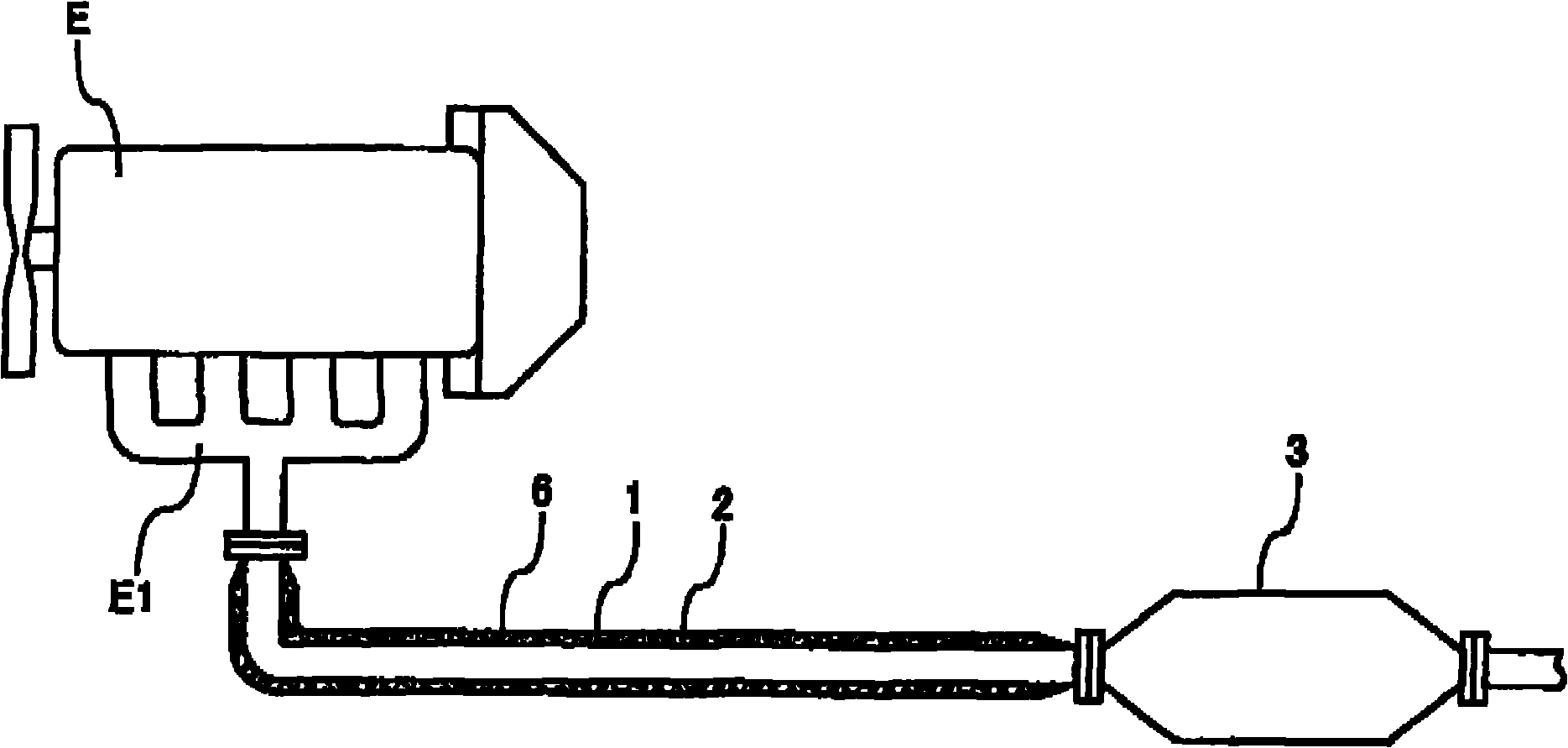

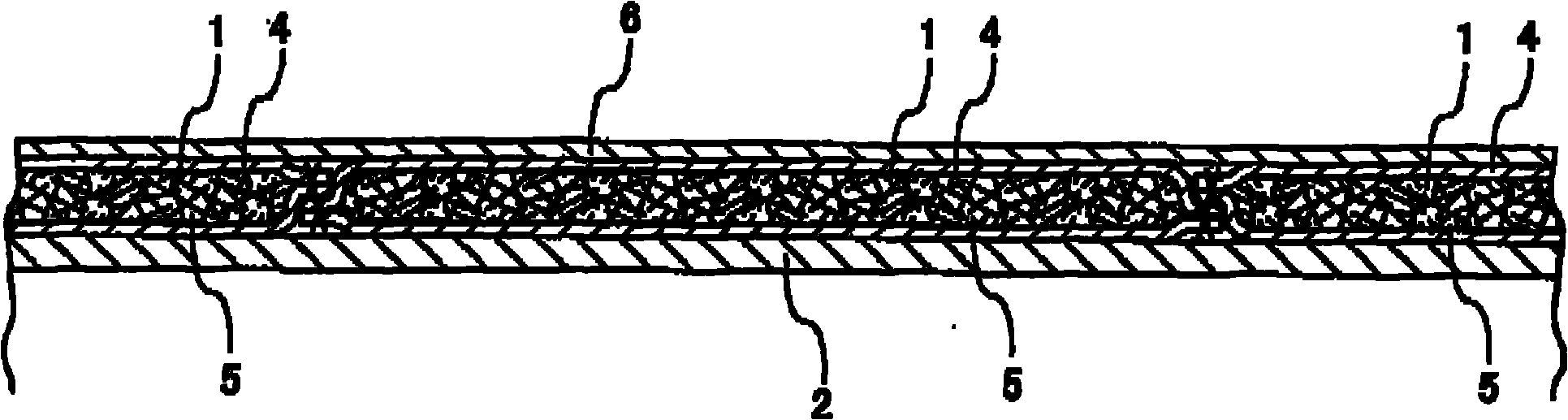

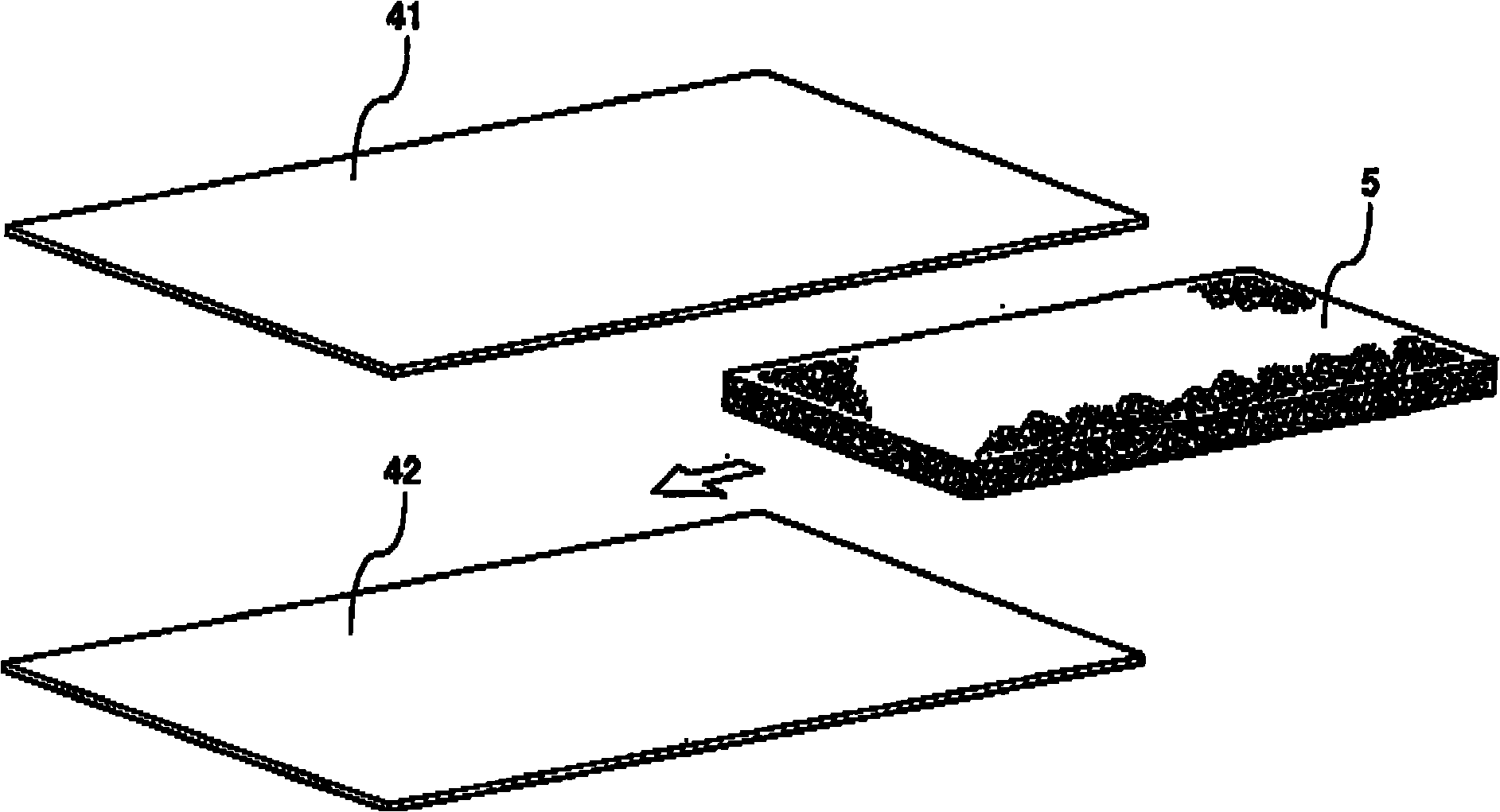

[0019] exist figure 1 Among them, the heat insulating body 1 of the present invention is arranged on the outer periphery of the exhaust pipe 2 from the upstream end of the vehicle exhaust pipe 2 connected to the exhaust manifold E1 of the engine E until it is arranged on the exhaust pipe 2. The inlet side of the catalyst device 3 midway. The enlarged cross-sectional view of the insulation body 1 is in figure 2 Indicated. The thermal insulation body 1 is equipped with a certain length of bag-shaped part 4 along the exhaust pipe 2. Actually, as shown in the figure, the necessary number of thermal insulation bodies 1 are adjacent to each other and wrapped around the outer circumference of the exhaust pipe 2, covering the exhaust manifold E1 The outer periphery of the exhaust pipe 2 between the catalyst device 3 . A deformable plate-shaped thermal insulation material 5 with a thickness of 5 to 15 mm is inserted inside each bag-shaped member 4 , and the inside of the bag-shaped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com